Titanium Machining Difficulties

The thermal conductivity of titanium alloy is small, so the cutting temperature is very high when processing titanium alloy. Under the same conditions, the cutting temperature of processing TC4[i] is more than double that of No. 45 steel, and the heat generated during processing is difficult to pass through the workpiece. Release; the specific heat of titanium alloy is small, and the local temperature rises quickly during processing. Therefore, the temperature of the tool is very high, the tool tip is sharply worn, and the service life is reduced.

The low elastic modulus of titanium alloy[ii] makes the machined surface prone to springback, especially the machining of thin-walled parts is more serious, which is easy to cause strong friction between the flank and the machined surface, thereby wearing the tool and chipping. blade.

Titanium alloy has strong chemical activity, and it is easy to interact with oxygen, hydrogen and nitrogen at high temperature, which increases its strength and reduces its plasticity. The oxygen-rich layer formed during heating and forging makes machining difficult.

Machining principles of titanium alloy materials[1-3]

In the machining process, the selected tool material, cutting conditions and cutting time will affect the efficiency and economy of titanium alloy cutting.

1. Select a reasonable tool material

According to the properties, processing methods and processing technical conditions of titanium alloy materials, the tool materials should be selected reasonably. The tool material should be selected more commonly used, low price, good wear resistance, high thermal hardness, and has sufficient toughness.

2. Improve cutting conditions

The rigidity of the machine-fixture-tool system is better. The clearance of each part of the machine tool should be adjusted well, and the radial runout of the spindle should be small. The clamping work of the fixture should be firm and rigid enough. The cutting part of the tool should be as short as possible, and the thickness of the cutting edge should be increased as much as possible when the chip tolerance is sufficient to improve the strength and rigidity of the tool.

3. Appropriate heat treatment of the processed material

The properties and metallographic structure of titanium alloy materials are changed by heat treatment [iii], so as to improve the machinability of materials.

4. Choose a reasonable cutting amount

Cutting speed should be low. Because the cutting speed has a great influence on the temperature of the cutting edge, the higher the cutting speed, the sharper increase in the temperature of the cutting edge, and the temperature of the cutting edge directly affects the life of the tool, so it is necessary to choose the appropriate cutting speed.

Send your message to us:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts for Italy

-

CNC Machining Aluminum Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium and Titanium Alloy Fittings

-

Titanium and Titanium Alloy Forgings

-

Titanium and Titanium Alloy Wires

-

Titanium Bars

-

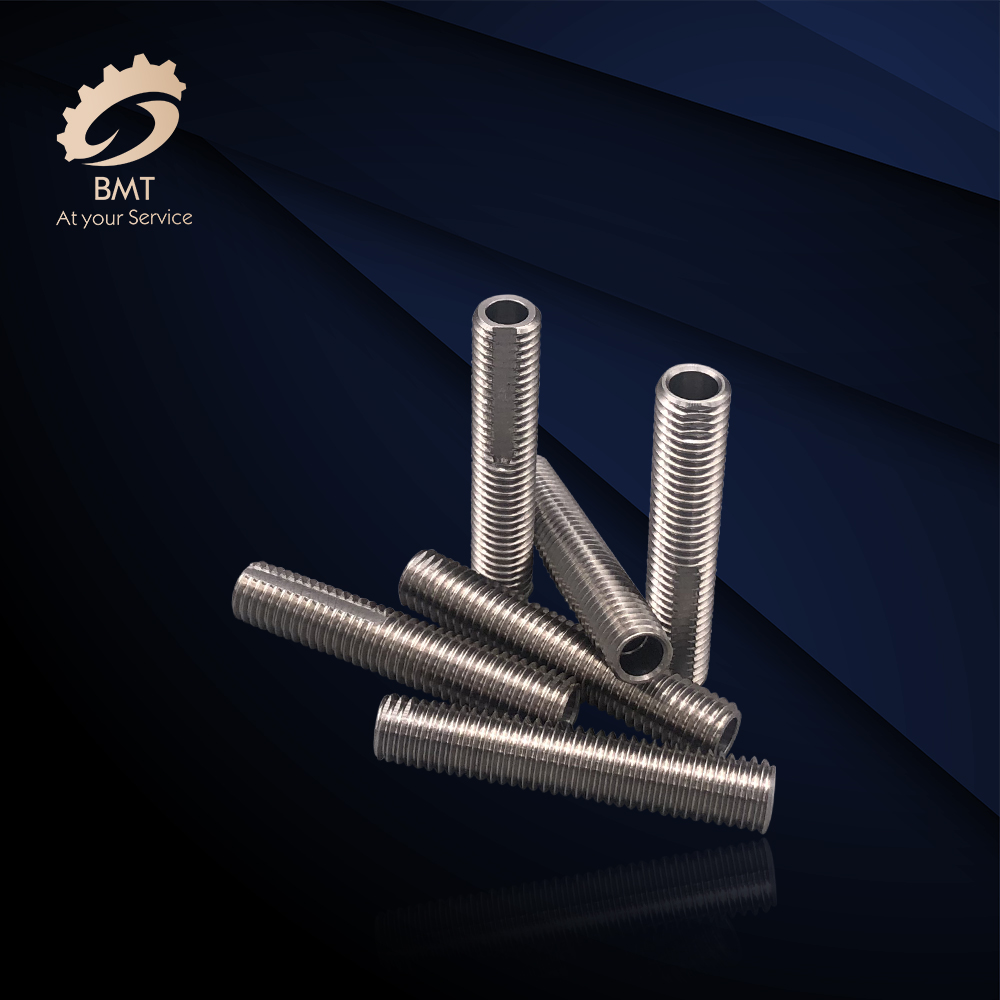

Titanium Seamless Pipes/Tubes

-

Titanium Welded Pipes/Tubes