Titanium Machining Difficulties

(1) The deformation coefficient is small:

This is a relatively obvious feature in the machining of titanium alloy materials. In the process of cutting, the contact area between the chip and the rake face is too large, and the stroke of the chip on the rake face of the tool is much larger than that of the general material. Such a long-term walking will cause serious tool wear, and Friction also occurs during walking, which increases the temperature of the tool.

(2) High cutting temperature:

On the one hand, the small deformation coefficient mentioned above will lead to a part of the temperature increase. The main aspect of the high cutting temperature in the titanium alloy cutting process is that the thermal conductivity of the titanium alloy is very small, and the length of the contact between the chip and the rake face of the tool is short.

Under the influence of these factors, the heat generated during the cutting process is It is difficult to transmit it out, and it mainly accumulates near the tip of the tool, causing the local temperature to be too high.

(3) The thermal conductivity of titanium alloy is very low:

The heat generated by cutting is not easily dissipated. The turning process of titanium alloy is a process of large stress and large strain, which will generate a lot of heat, and the high heat generated during processing cannot be effectively diffused. On the blade, the temperature rises sharply, the blade softens, and the tool wear is accelerated.

The specific strength of titanium alloy products is very high among metal structural materials. Its strength is comparable to that of steel, but its weight is only 57% of that of steel. In addition, titanium alloys have the characteristics of small specific gravity, high thermal strength, good thermal stability and corrosion resistance, but titanium alloy materials are difficult to cut and have low processing efficiency. Therefore, how to overcome the difficulty and low efficiency of titanium alloy processing has always been an urgent problem to be solved.

Send your message to us:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

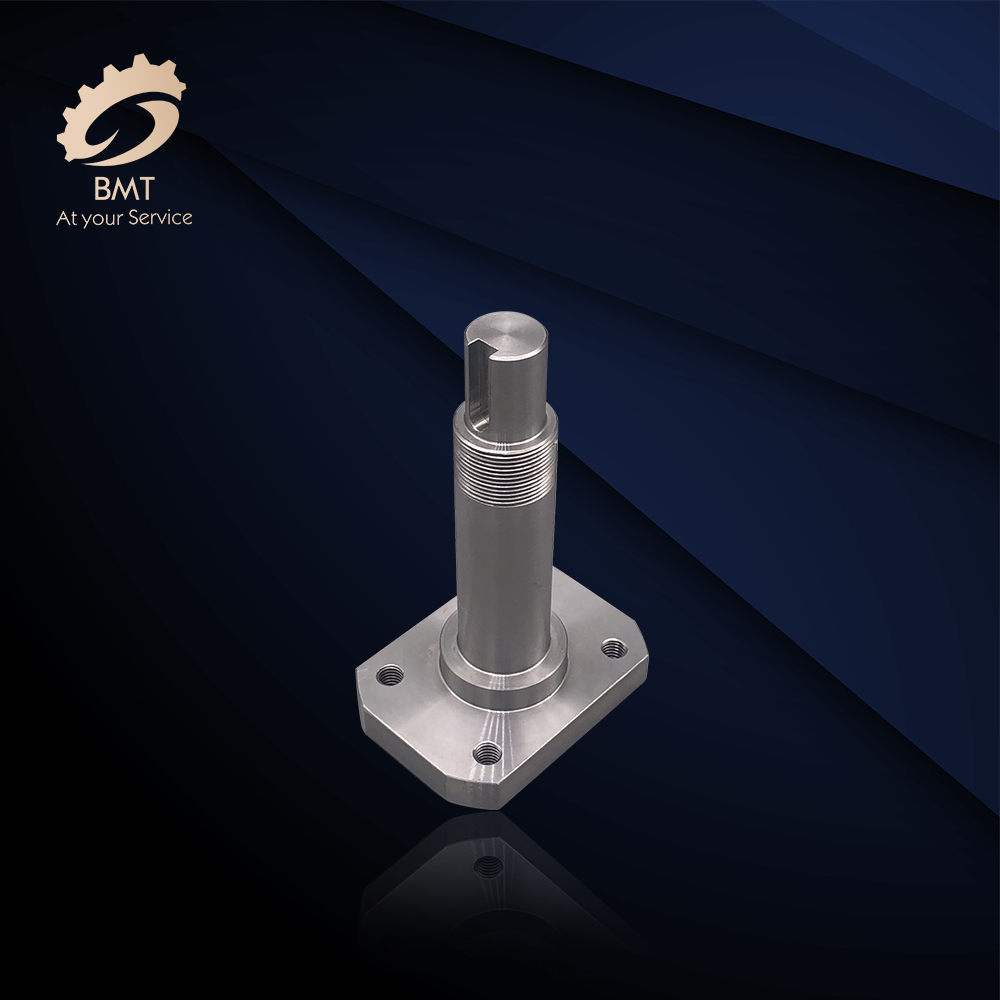

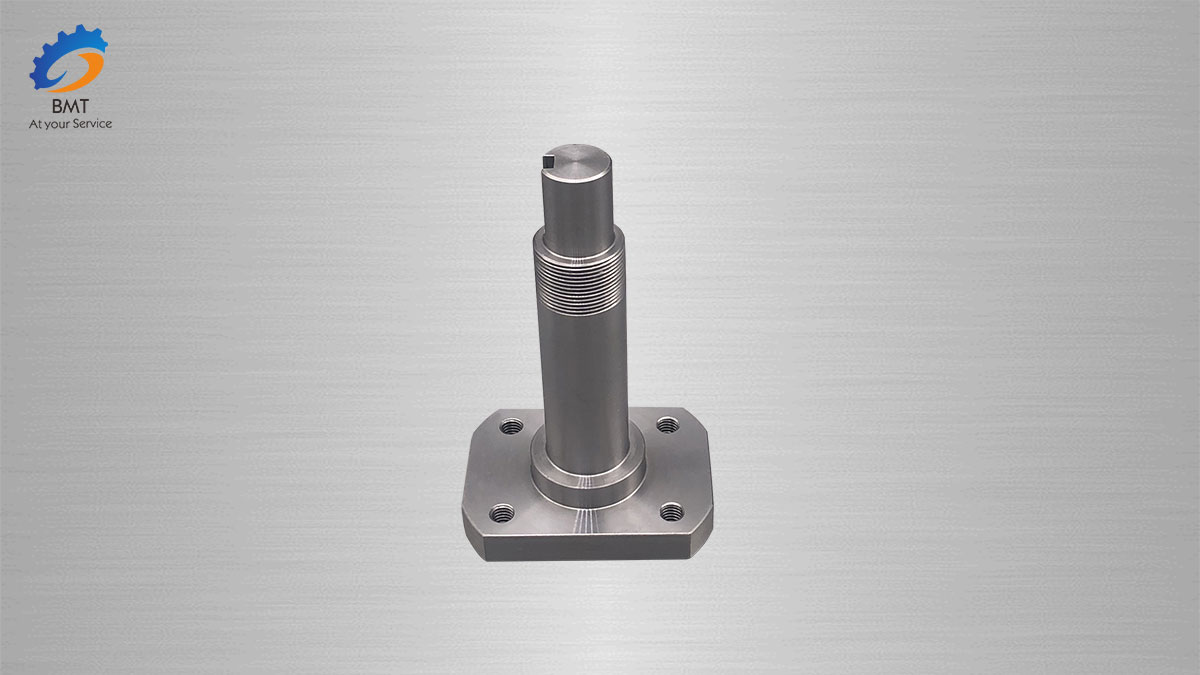

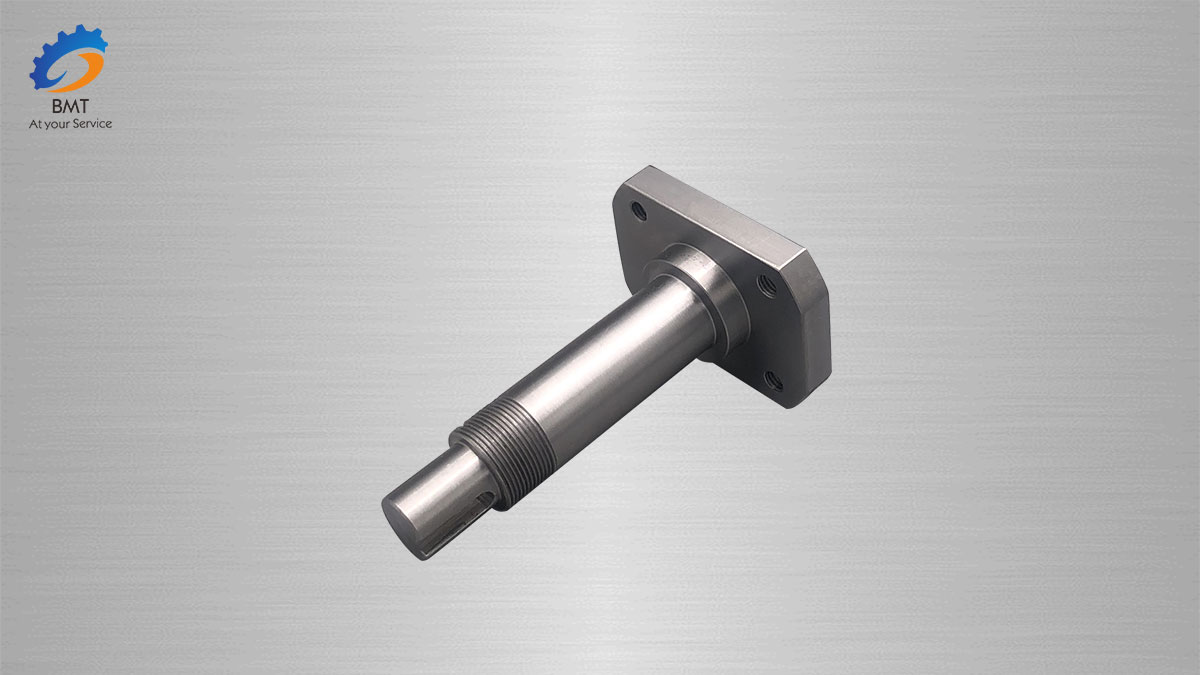

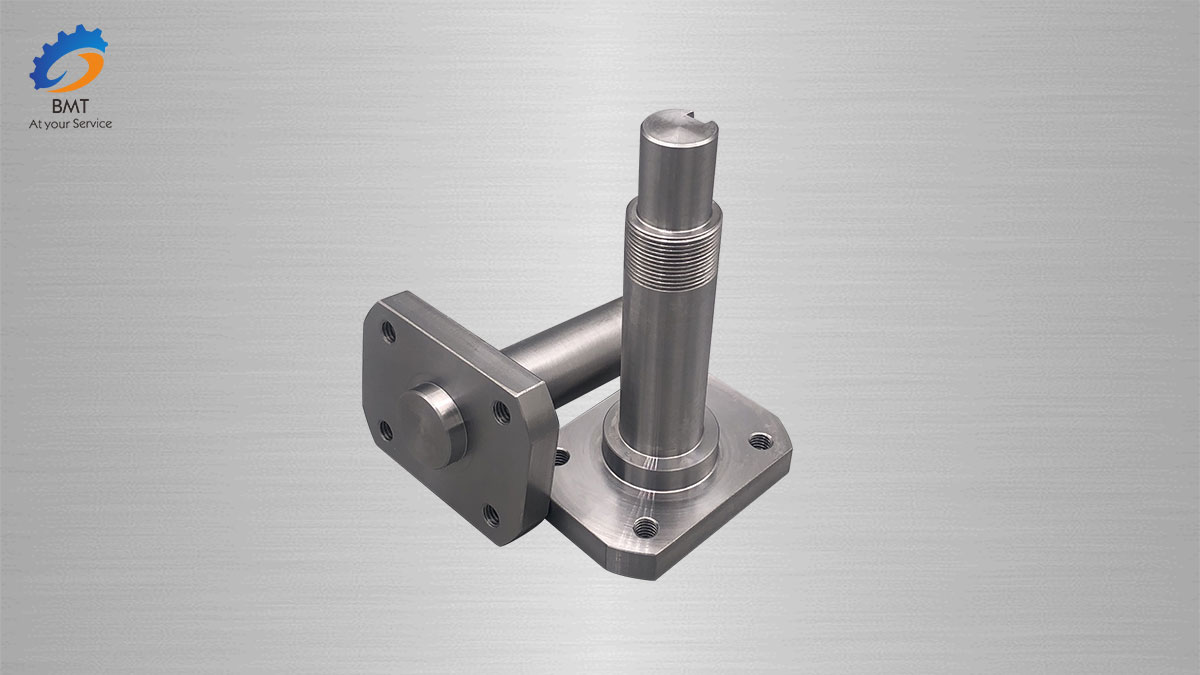

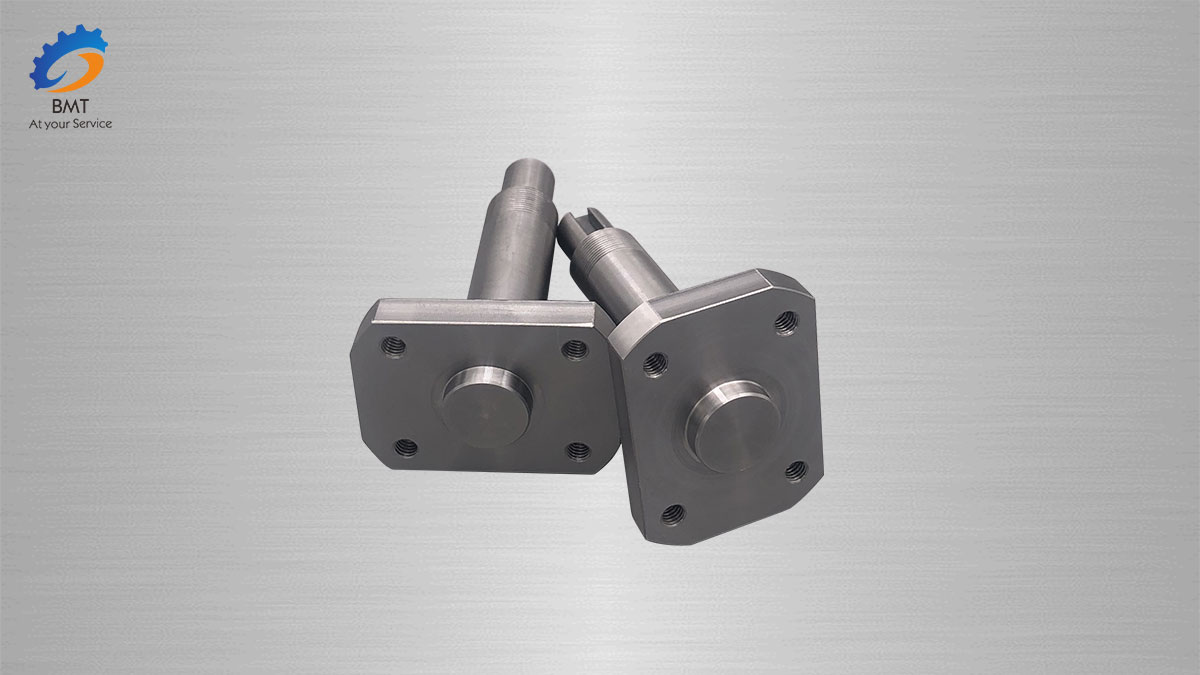

Axis High Precision CNC Machining Parts

-

CNC Machined Parts for Italy

-

CNC Machining Aluminum Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium and Titanium Alloy Fittings

-

Titanium and Titanium Alloy Forgings

-

Titanium and Titanium Alloy Wires

-

Titanium Bars

-

Titanium Seamless Pipes/Tubes

-

Titanium Welded Pipes/Tubes