Titanium and Titanium Alloy Bars

BMT is specialized in producing premium titanium forging and titanium alloy forging featuring excellent mechanical capacity, tenacity, corrision resistance, low density and high intensity. BMT titanium products’ standard production and detection procedure have overcome both the technological complexity and machining difficulty of titanium forging manufacturing.

The high quality precision titanium foging production is based on our professional process design and gradually progressive method. BMT titanium forging can be applied to the range from the small skeleton supporting structure to large-size titanium forging for aircrafts.

BMT titanium forging are widely used in many industries, such as aerospace, offshore engineering, oil & gas, sports, food, automobile, mining industries, military, marine, etc. Our annual production capacity is up to 10,000 tons.

Titanium and Titanium Fittings:

Elbow (90° and 45° 3D/1.5D/2.5D/5D Elbow)

Reducer Tee, Equal Tee and Concentric Reducer And Eccentric Reducer

Stub Ends

Welded and Seamless Pipes

Pipe Cap

Flanges, etc.

Standard:

ASTM/ASME B381

Materials:

F1 (Gr. 1), F2 (Gr. 2), F3 (Gr. 3), F4 (Gr. 4), F5 (Gr. 5), F7 (Gr. 7), F9 (Gr. 9), F11 (Gr. 11), F12 (Gr. 12), F16 (Gr. 16).

BMT has already provided more than 1000 tons titanium and titanium alloy fittings, welded pipes, flanges, etc to overseas prefabrication projects. Quality is our Culture.

All photos shown here are the products we'va made for our esteemed customers and got good complimentary. We give reasonable prices with perfect quality and acceptable delivery time.

BMT's Titanium products are our new products range, except CNC Machined Parts and Sheet Metal Works. Meanwhile, we also provided Titanium and Titanium Alloy CNC Custom Machined Part.

We perennially produce and export ASTM standard titanium fittings and Chinese Standard (GB) standard titanium fittings, and titanium fittings of mutually agreed standard.

Being on of the few manufacturers that can realize quality control on the whole production process, we execute strict quality control all the way from the raw material smelting of titanium sponge to the finished products.

Having premium quality and impeccable tracking and service, we sell products including medical titanium fittings, all over the world. We have become one of the biggest suppliers and exporters of titanium fittings in China.

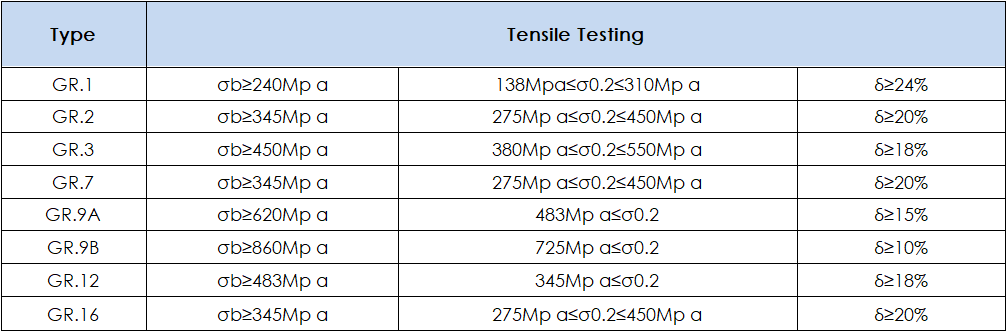

Available Material Chemical Composition

Available Material Chemical Composition

Inspection test:

- NDT Test

- Ultrasonic Test

- LDP Test

- Ferroxyl Test

Productivity (Max and Min amount of Order): Unlimited, according to order.

Lead Time: The general lead time is 30 days. However, it depends on the amount of the order accrdingly.

Transportation: The general way of transportation is by Sea, by Air, by Express, by Train, which shall be selected by customers.

Packing:

- Pipe ends to be protected with plastic or cardboard caps.

- All fittings to be packed to protect ends and facing.

- All other goods will be packed by foam pads and related plastic packing and plywood cases.

- Any wood used for packing must be suitable to prevent contamination by contact with handling equipment.