Custom Made CNC Machining Parts Service

CNC Machined Parts

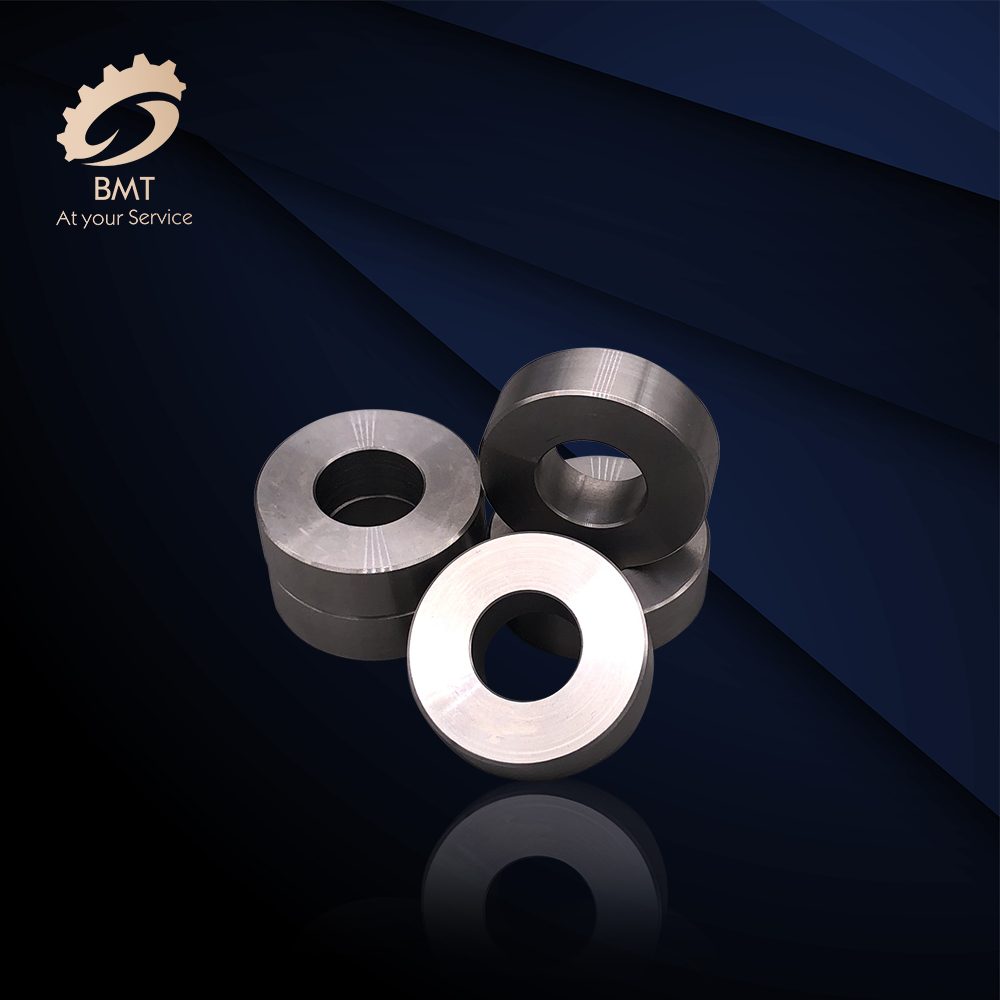

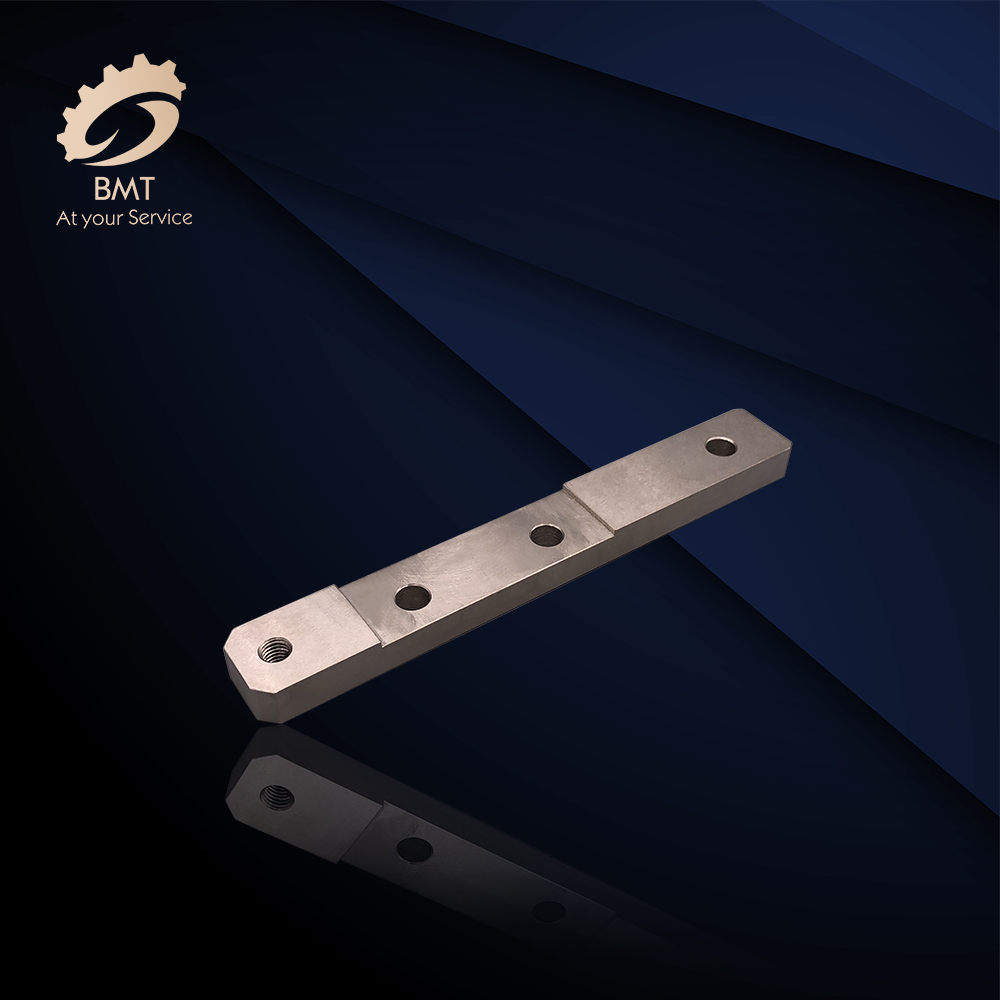

CNC machined parts can often vary in complexity. From simple planar parts to demanding, highly complex curved geometries, it’s vital to choose the correct CNC machine for the job. Different types of CNC machines exist and can be used for different parts.

The type of machine used (CNC lathe, 3 axis CNC milling machine or 4/5 axis machining center, etc) will usually be determined by the complexity of the part. Part complexity, geometry and dimensions affect the type of machine chosen, alongside tolerances, end-use of the product, and the type of material.

CNC Machined Parts

CNC machined parts can often vary in complexity. From simple planar parts to demanding, highly complex curved geometries, it’s vital to choose the correct CNC machine for the job. Different types of CNC machines exist and can be used for different parts.

The type of machine used (CNC lathe, 3 axis CNC milling machine or 4/5 axis machining center, etc) will usually be determined by the complexity of the part. Part complexity, geometry and dimensions affect the type of machine chosen, alongside tolerances, end-use of the product, and the type of material.

CNC Design

Widely speaking, a more complex part will require more consideration during machining due to its design, specific dimensions and requirements. Design engineers should always, where possible, work to create simple, easy to produce parts while the part is in the design process. The simpler the design, the easier it will be to manufacture, and, by default, the cheaper the overhead costs will be.

Mechanical designers are always considering how to create designs that require fewer components while offering maximum performance. This can drive costs down while also ensuring efficiency and higher output.

CNC Design

Widely speaking, a more complex part will require more consideration during machining due to its design, specific dimensions and requirements. Design engineers should always, where possible, work to create simple, easy to produce parts while the part is in the design process. The simpler the design, the easier it will be to manufacture, and, by default, the cheaper the overhead costs will be.

Mechanical designers are always considering how to create designs that require fewer components while offering maximum performance. This can drive costs down while also ensuring efficiency and higher output.

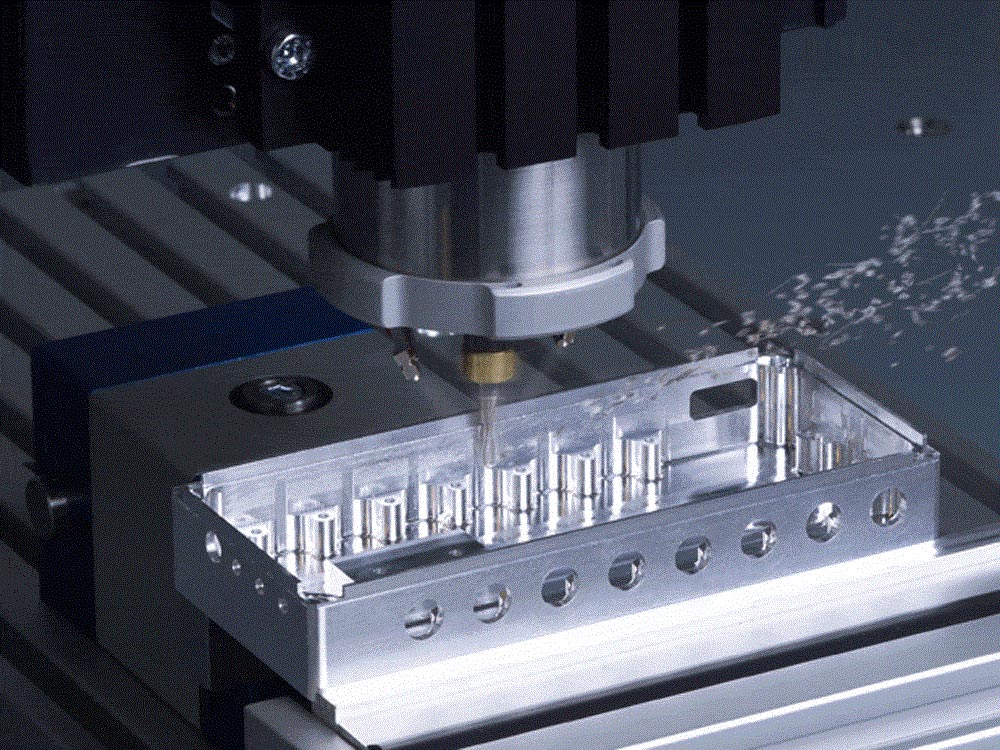

The complexity of components is always a consideration for mechanical designers, and high-performance components that are efficiently designed will consider the machining lead time. Precision engineering can reduce the risk often caused by human error. Small errors in measurement, execution or production can lead to projects and products being entirely compromised. With this in mind, it is worth ensuring you are working with experienced designers, engineers and manufacturers.

Having said that, complex CNC machining will be needed, where high levels of accuracy and finishing may result in a longer lead time. The general rule is that 4/5 axis CNC Machining will be needed for a complex part and complex shapes. This is because the machine can work to 4/5 different angles/axes to achieve the final shape, rather than two or three that operate on just X and Y.

By incorporating a further three axes, A, B and C, more accurate and complex parts can be machined, without the need to re-orientate the part manually within the machine. The fact that 5 axis CNC milling can offer ‘single setup’ is a large, time-reducing benefit.

High accuracy of tools and experienced operators can help ensure that the required part can be produced with highly accurate results and a fast lead time. It is always worth getting in contact with an experienced manufacturer to enquire about their machining capabilities and how they can best help you. At BMT, we can offer a free 24 Hour Quote; see how we can help your project today. Get it.