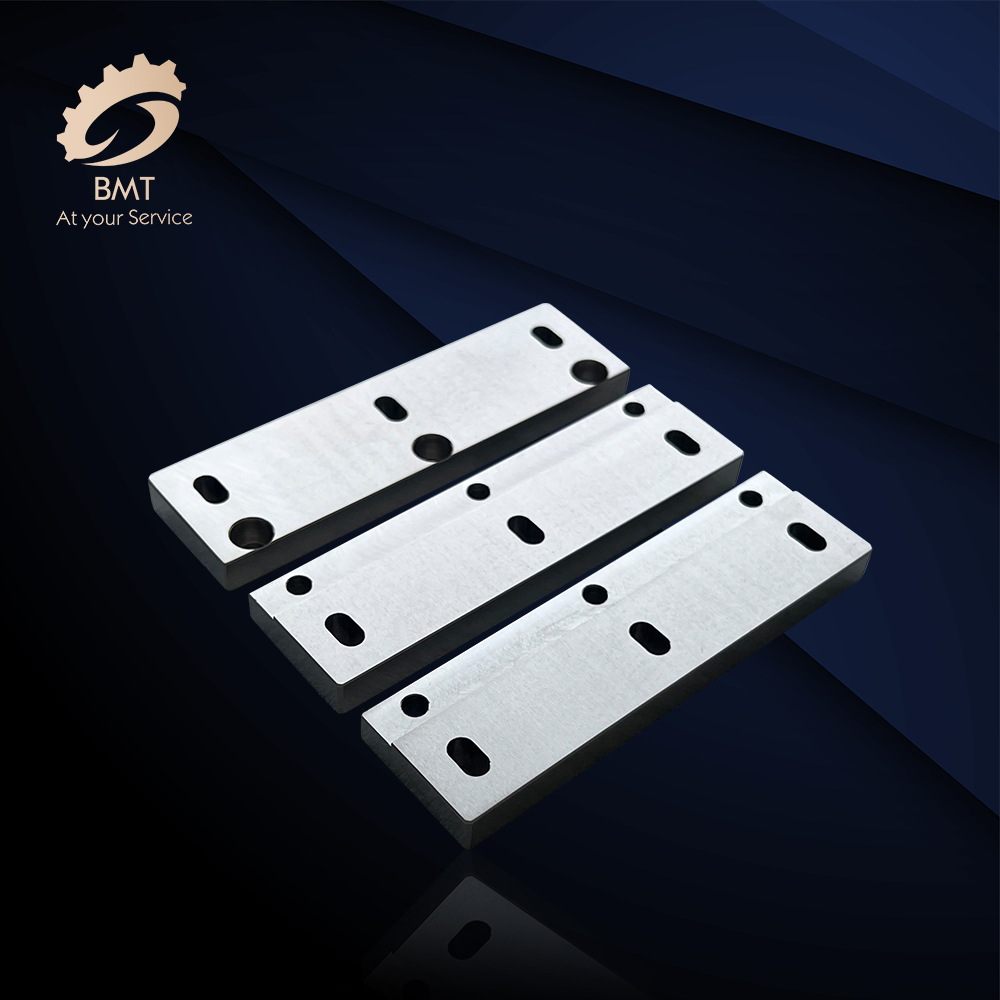

Mold Machining Parts Manufacturer

Introducing our high-quality Mold Machining Parts, designed to meet the demands of precision engineering and manufacturing. Our Mold Machining Parts are crafted with precision and attention to detail, ensuring that they meet the exact specifications required for molds used in various industries such as automotive, aerospace, and consumer goods. Our Mold Machining Parts are manufactured using the latest technologies and techniques, ensuring that each part is made with precision and accuracy. We understand the importance of precision in mold machining, and our parts are designed to meet the highest standards of quality and performance.

Our Mold Machining Parts are made from high-quality materials, ensuring that they are durable and long-lasting. Whether you need core pins, ejector pins, or any other mold machining parts, you can trust that our products will meet and exceed your expectations. One of the key features of our Mold Machining Parts is their precision and accuracy. We take great care to ensure that each part is manufactured to the tightest tolerances, ensuring that they fit perfectly and function flawlessly within your molds. This level of precision is essential for ensuring the quality and consistency of the products that are being manufactured using these molds.

In addition to their precision, our Mold Machining Parts are also designed for ease of use and maintenance. We understand that time is of the essence in the manufacturing industry, and our parts are designed to be easy to install and maintain, minimizing downtime and maximizing productivity. Our Mold Machining Parts are also designed to be versatile and adaptable, ensuring that they can be used in a wide range of mold types and configurations. Whether you are working with injection molds, blow molds, or compression molds, you can trust that our parts will meet your needs and specifications.

We take great pride in the quality of our Mold Machining Parts and are committed to providing our customers with the best products and service possible. Our team of highly skilled engineers and technicians are dedicated to ensuring that each part is manufactured to the highest standards, and we are constantly striving to improve and innovate our products to meet the evolving needs of the industry.

When it comes to mold machining, precision and quality are of the utmost importance. With our Mold Machining Parts, you can trust that you are getting the best products available. Whether you are a mold manufacturer, a tool and die maker, or a production manager, you can rely on our parts to help you meet your manufacturing needs and achieve the highest levels of quality and efficiency.

Send your message to us:

-

Axis High Precision CNC Machining Parts

-

Titanium and Titanium Alloy Fittings

-

Titanium and Titanium Alloy Forgings

-

Titanium and Titanium Alloy Wires

-

Titanium Bars

-

Titanium Seamless Pipes/Tubes

-

Titanium Welded Pipes/Tubes

-

Aluminum CNC Machining Parts

-

Auto Parts Machining

-

CNC Auto Parts Machined Parts

-

CNC Machined Components

-

Aluminum Sheet Metal Fabrication

-

Automotive Industry

-

Centerless Grinding

-

CNC Machining Advantages

-

CNC Machining Aluminum Parts