Shorten Your Production Cycle

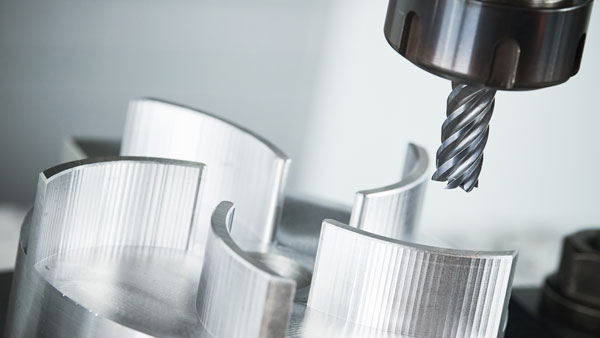

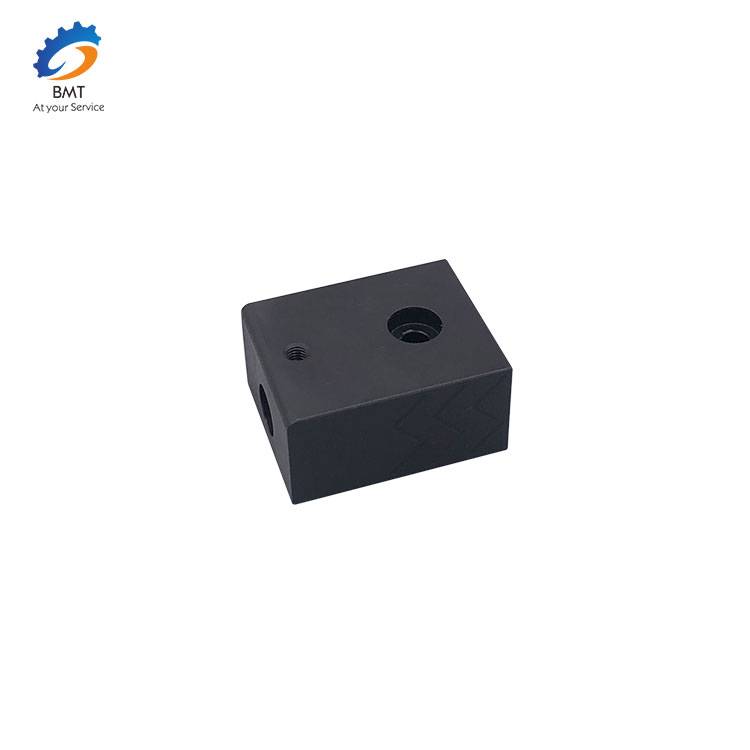

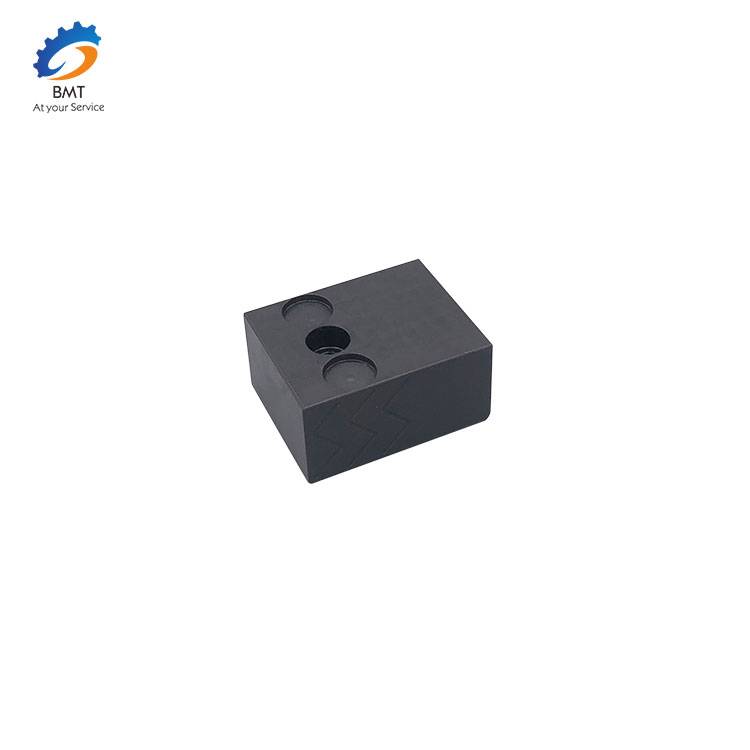

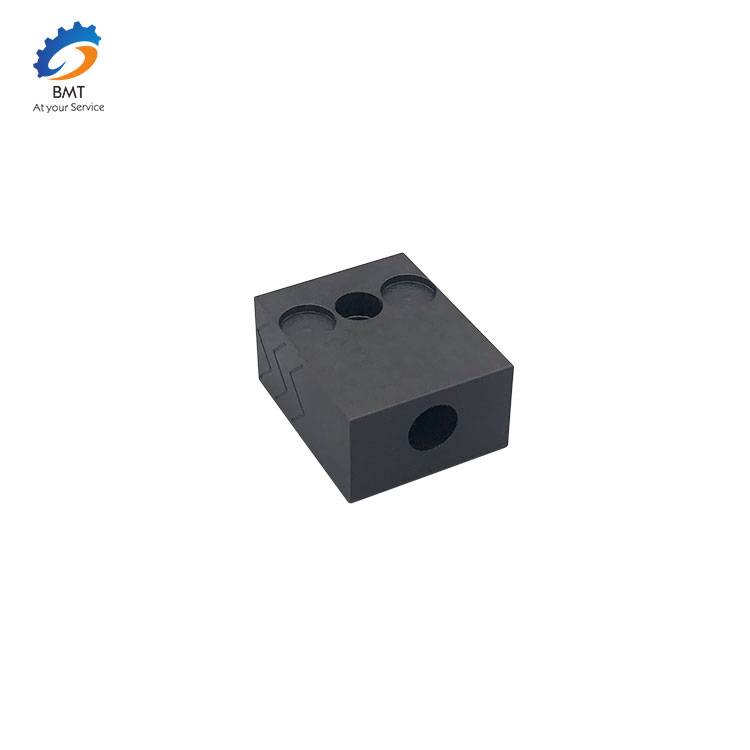

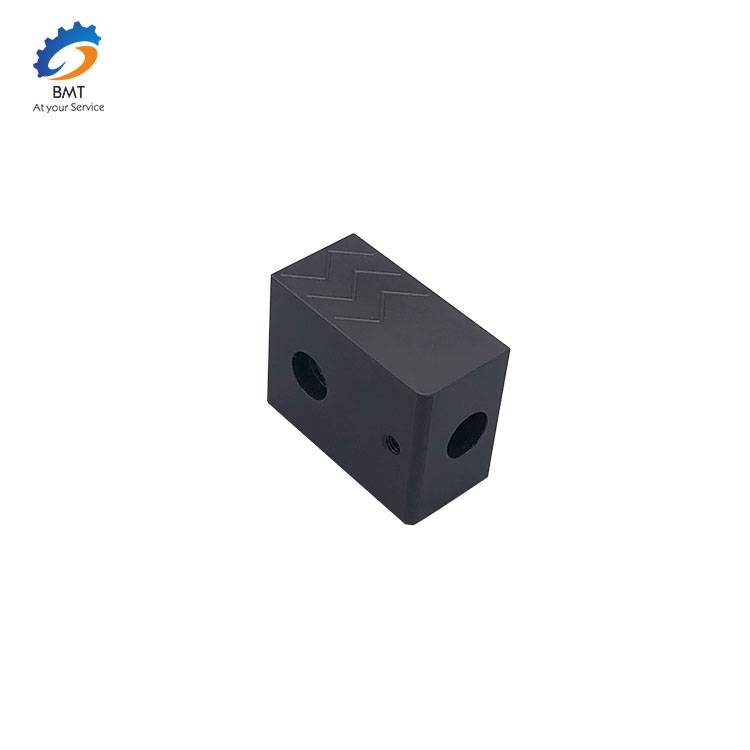

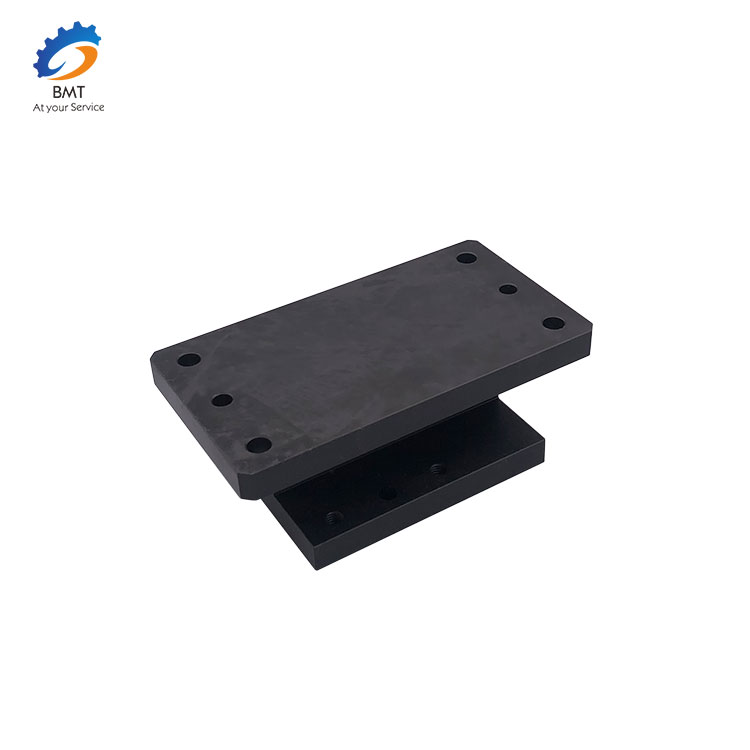

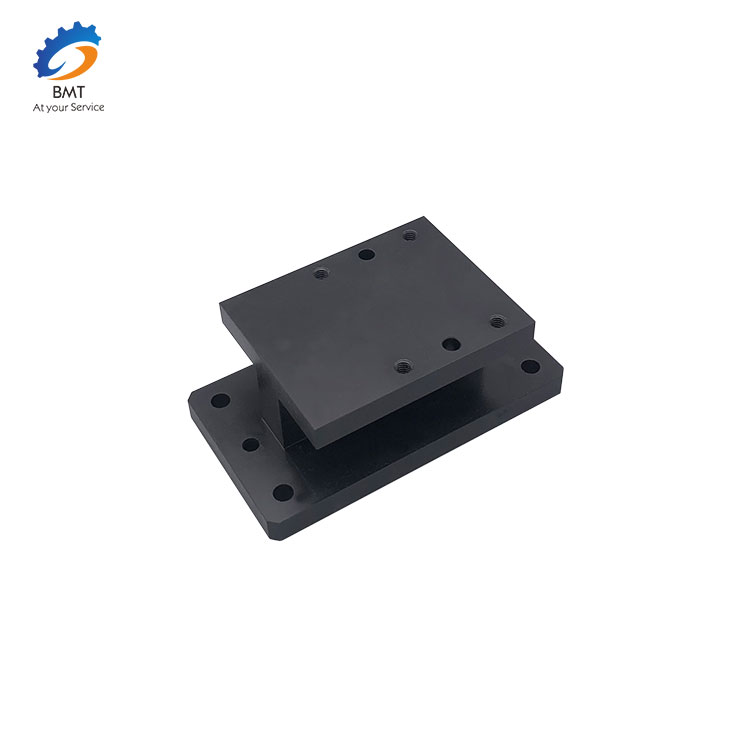

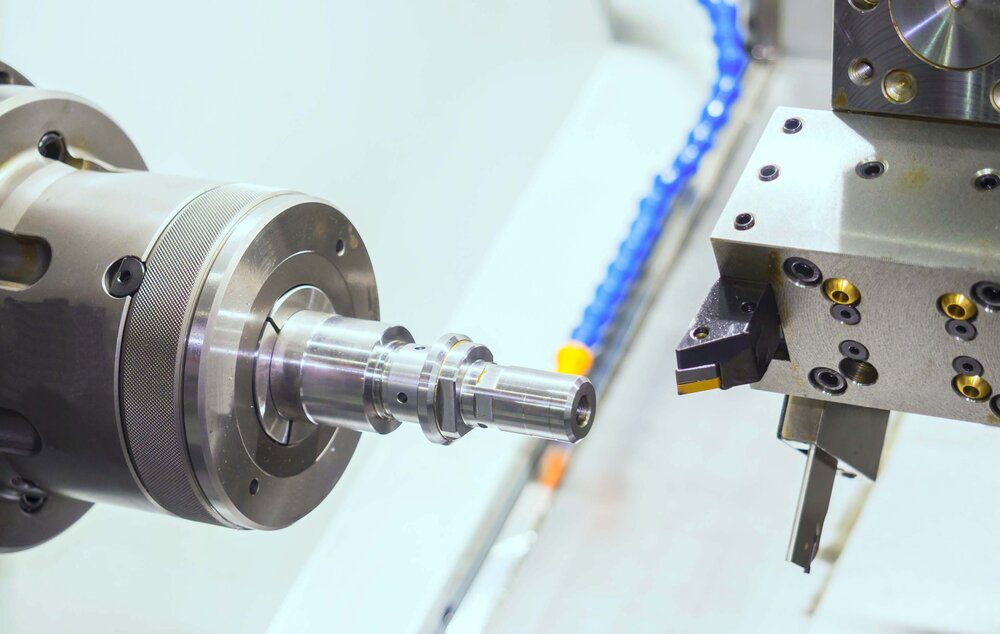

This manufacturing technique is a fully automated machine that uses computer-aided manufacturing software and computer-aided design. For parts with simpler designs, the operator can directly input the command programs into the machine. But for more complicated designs, a CAM or CAD drawing has to be generated first and integrated into the system. An alternative way is to use Coordinate Measuring Machines (CMMs) to physically map the instructions of the design into the system. The software will create and provide the steps needed for the machine automatically to create the parts we need.

There is less room for error because the machine will follow the instructions down the letter to create the product. What’s even better is that this operation is highly-repeatable, which allows the quicker production of identical parts.

The earlier applications of CNC machines are slower and are employed only for high volume production. Now, in BMT, technology has greatly improved. Using complex software and tools, it allows direct integration of computer-generated models to the program for the process to be even faster. This also allows using CNC machining services for low volume requirements to be more affordable and practical.

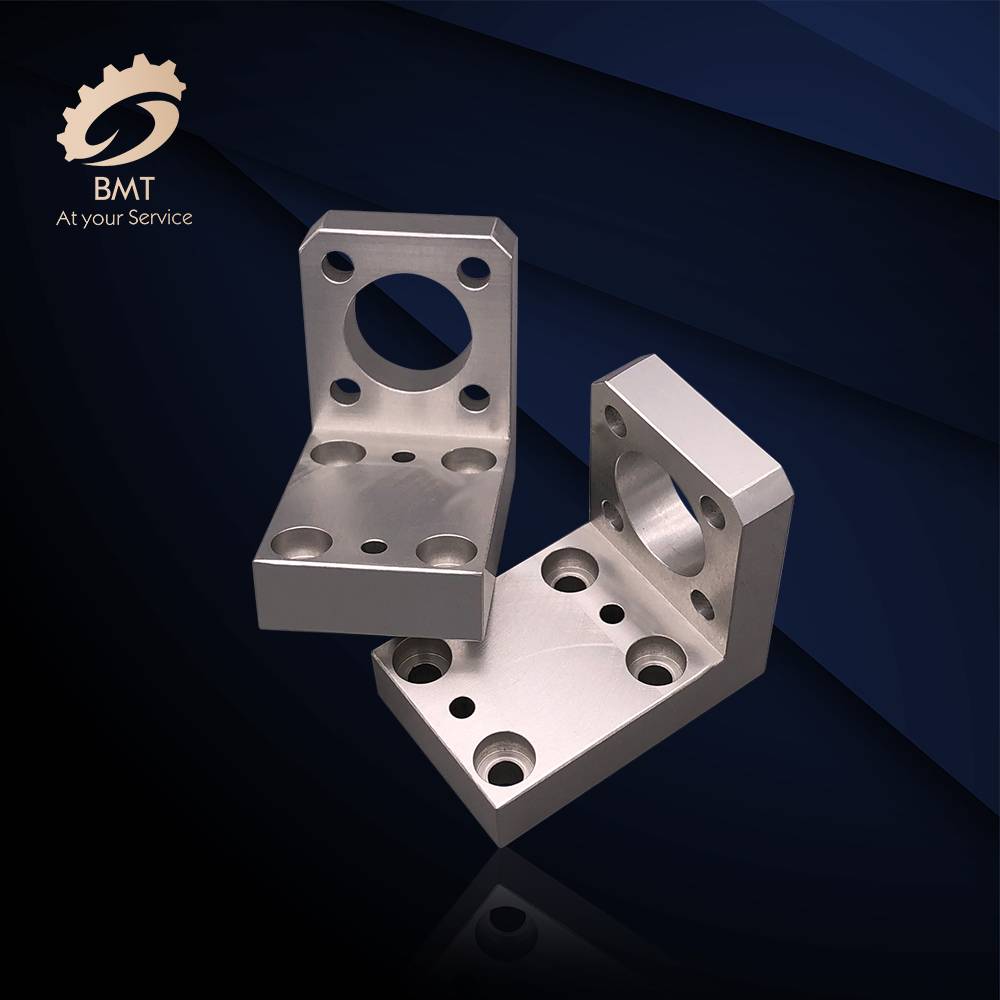

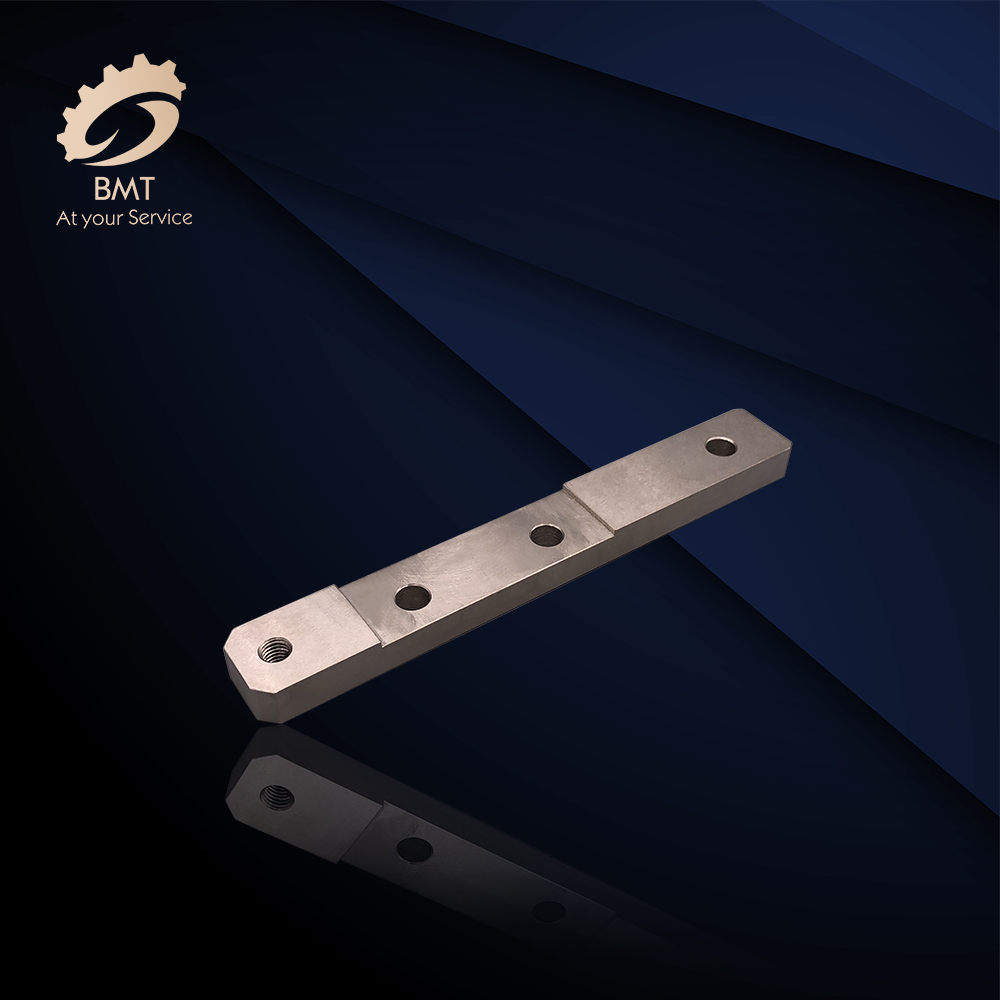

No matter what industry you are in or what your requirement is, with the use of our top CNC machining services, we can make prototypes, small-batch orders, and low volume production. Our company combines the use of cutting-edge technology, advanced machinery, and talented engineers and we can deliver the products to exceed your expectations. The CNC machines we have can withstand extreme conditions and environments for several applications in almost every industry.

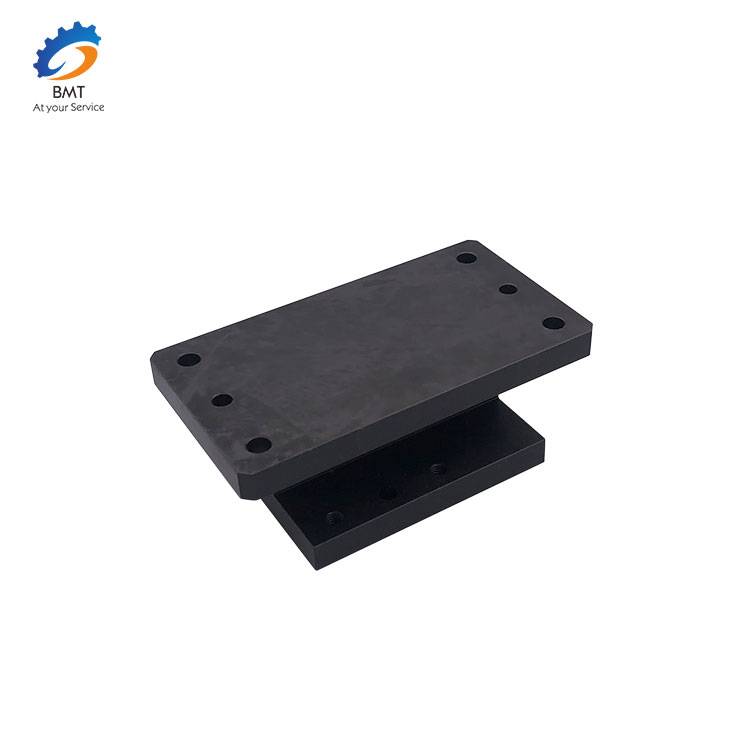

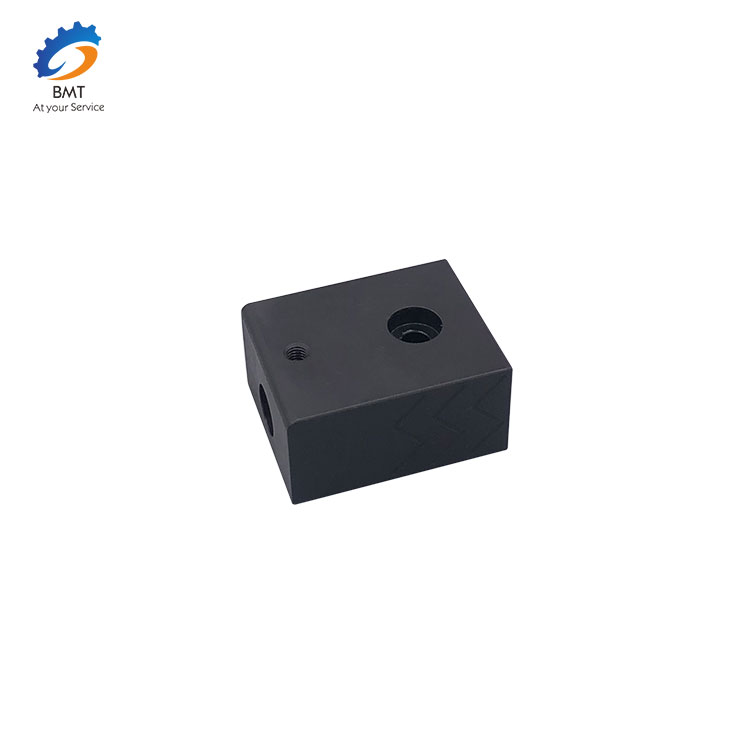

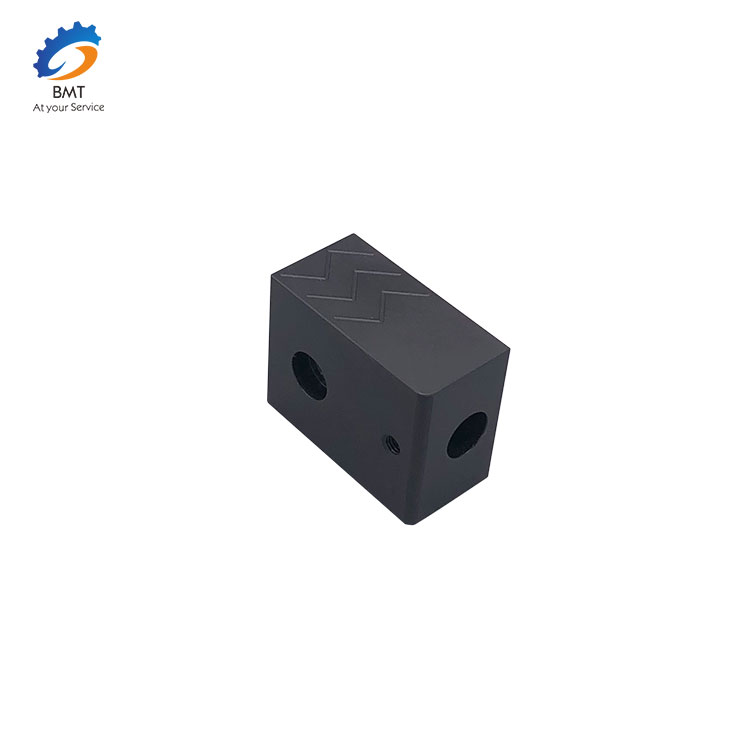

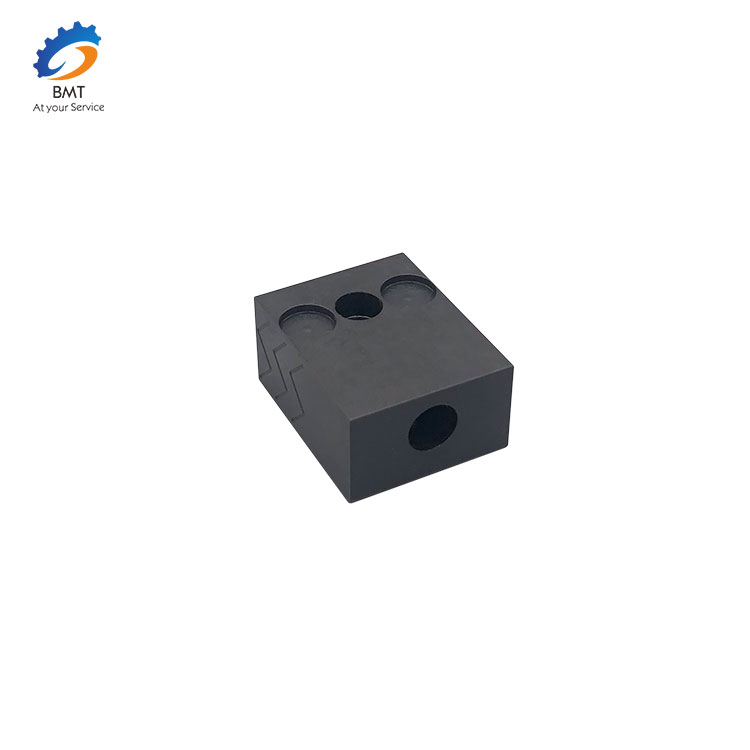

Metals and Plastic Materials

The metals and plastic materials we commonly employed are listed as below and you can choose as what you want:

| METALS | TOLERANCES | ADVANTAGES & CONSIDERATIONS | FINISH & APPEARANCE |

| Stainless Steel | +/- 0.005″ | High Strength High Corrosion Resistance High Weldability |

Standard Machined Finish with the appearance customer requests, like plating, anodizing, blasting, etc. |

| Carbon Steel | +/- 0.005″ | High Machinability High Weldability Can Be Hardened Not Corrosion Resistant |

|

| Aluminum | +/- 0.005″ | High StrengthHigh Strength Low Weight High Machinability Low Cost |

|

| Brass | +/- 0.005″ | High Strength Low Weight High Machinability Low Cost |

| PLASTICS | TOLERANCES | ADVANTAGES & CONSIDERATIONS | FINISH & APPEARANCE |

| HDPE | +/- 0.008″ | Medium Impact Strength Flexible |

Standard Machined Finish |

| PC | +/- 0.008″ | Medium Tensile High Impact Strength Maintains Properties Over Temperatures High Optical Clarity |

|

| ABS | +/- 0.008″ | Medium Tensile High Impact Strength Electrical Insulator High Machinability Low Cost |

|

| Acrylic | +/- 0.008″ | High Tensile Strength Can Be Polished |

|

| Nylon | +/- 0.008″ | High Tensile Medium Impact Strength Maintains Properties Over Temperatures |

|

| Delrin | +/- 0.008″ | Medium Tensile Medium Impact Strength Holds Machining Tolerances Well Good Wear & Fatigue Resistance |

|

| ULTEM | +/- 0.008″ | High Tensile Strength High Working Temperature Electrical Insulator High Optical Clarity |

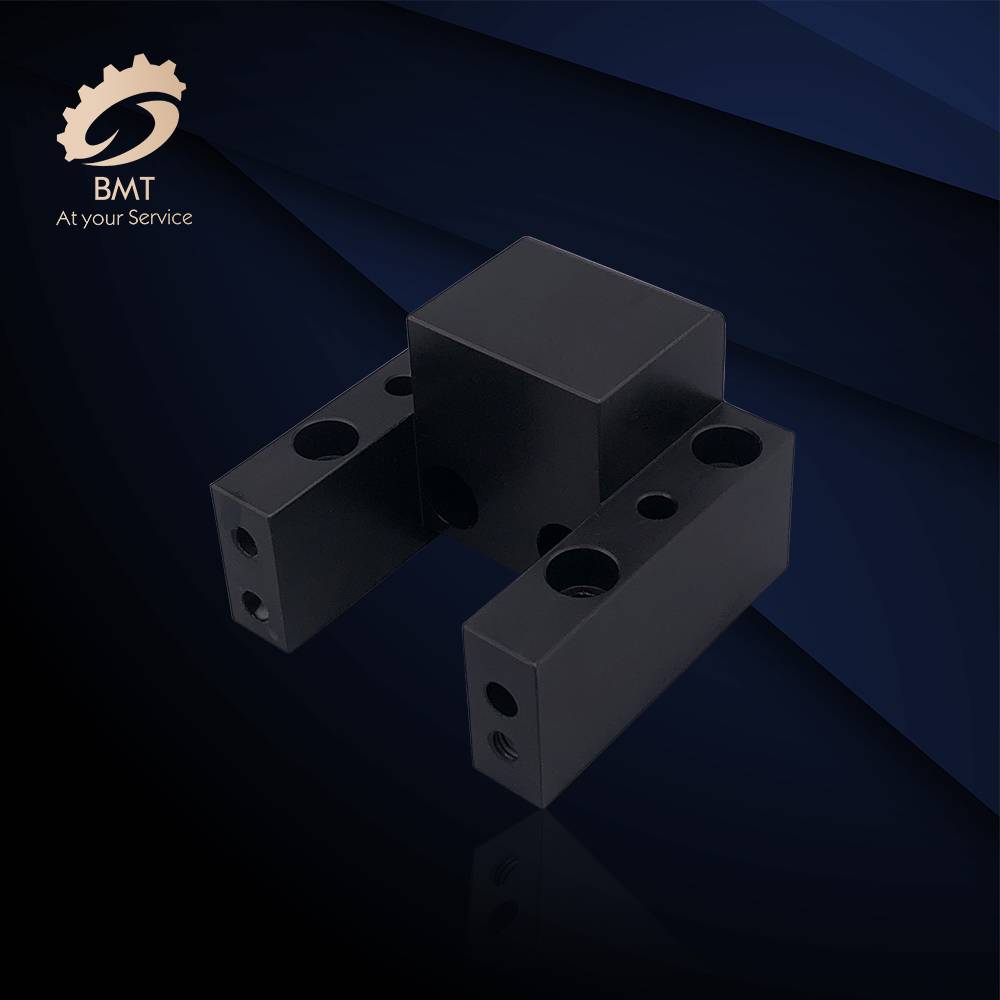

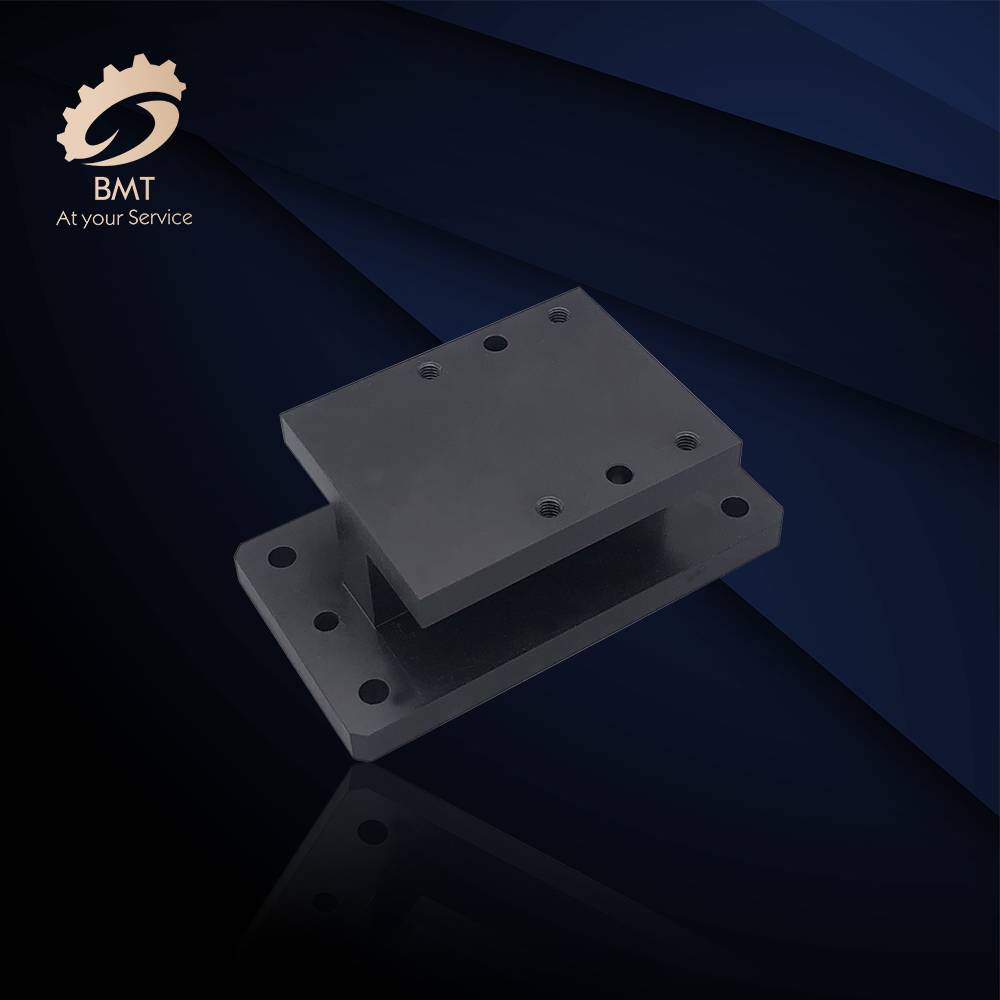

Do you want to shorten the production cycle and reduce your overall production cost?

BMT has the right solution. Simplify the manufacturing process with CNC machining services, which can help you speed up the production of large volume machined parts with the highest level of precision and accuracy.

In today’s manufacturing, outsourcing is the key. BMT can provide you with rapid CNC machining according to your specific requirements. All you need to do is to send the CAD files or drop an inquiry to our contact email. We provide you with a fast and free quote for CNC machining services and get you machined parts processed in the shortest time possible.