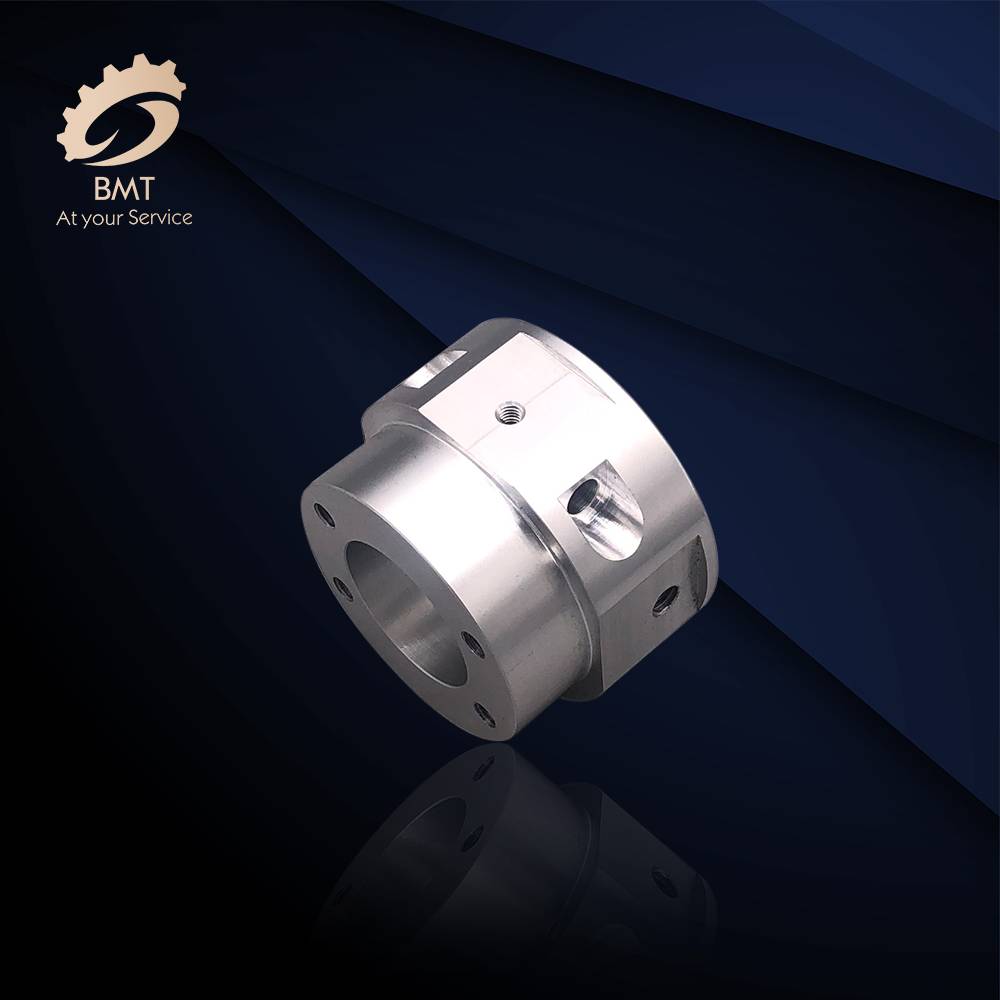

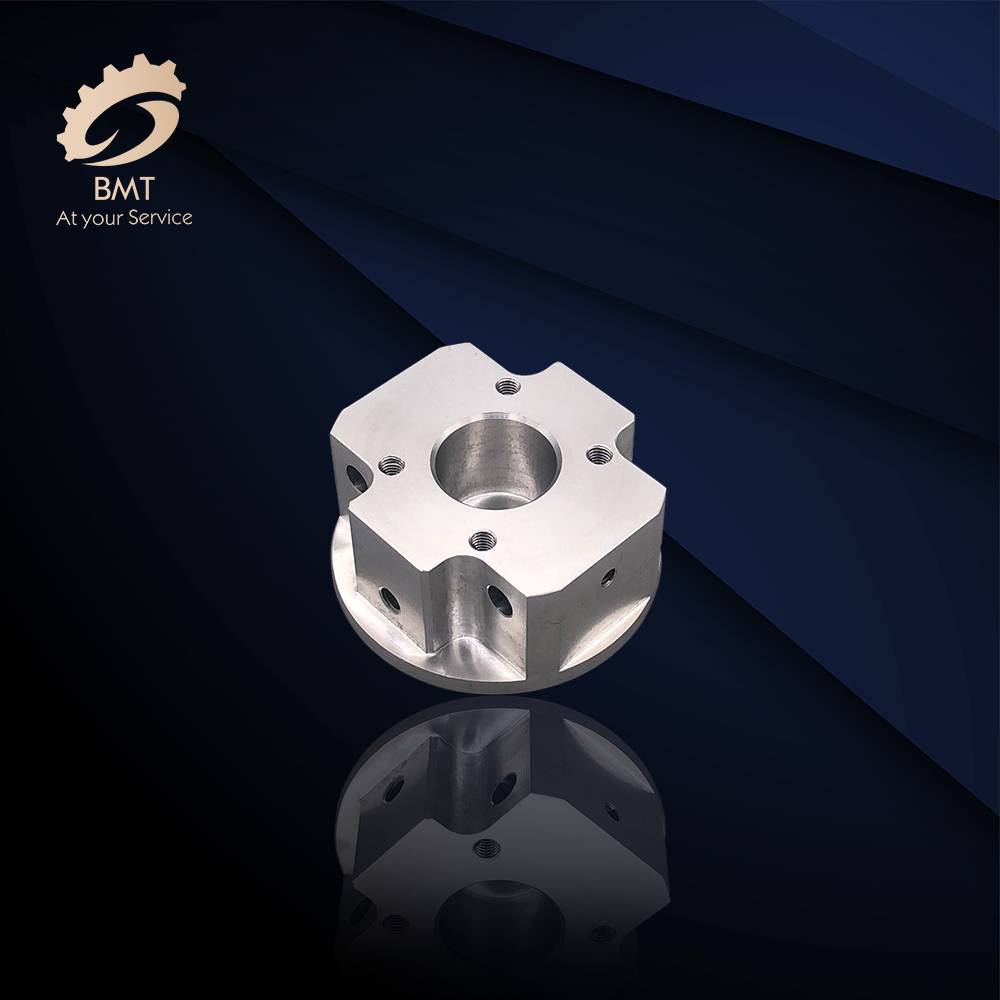

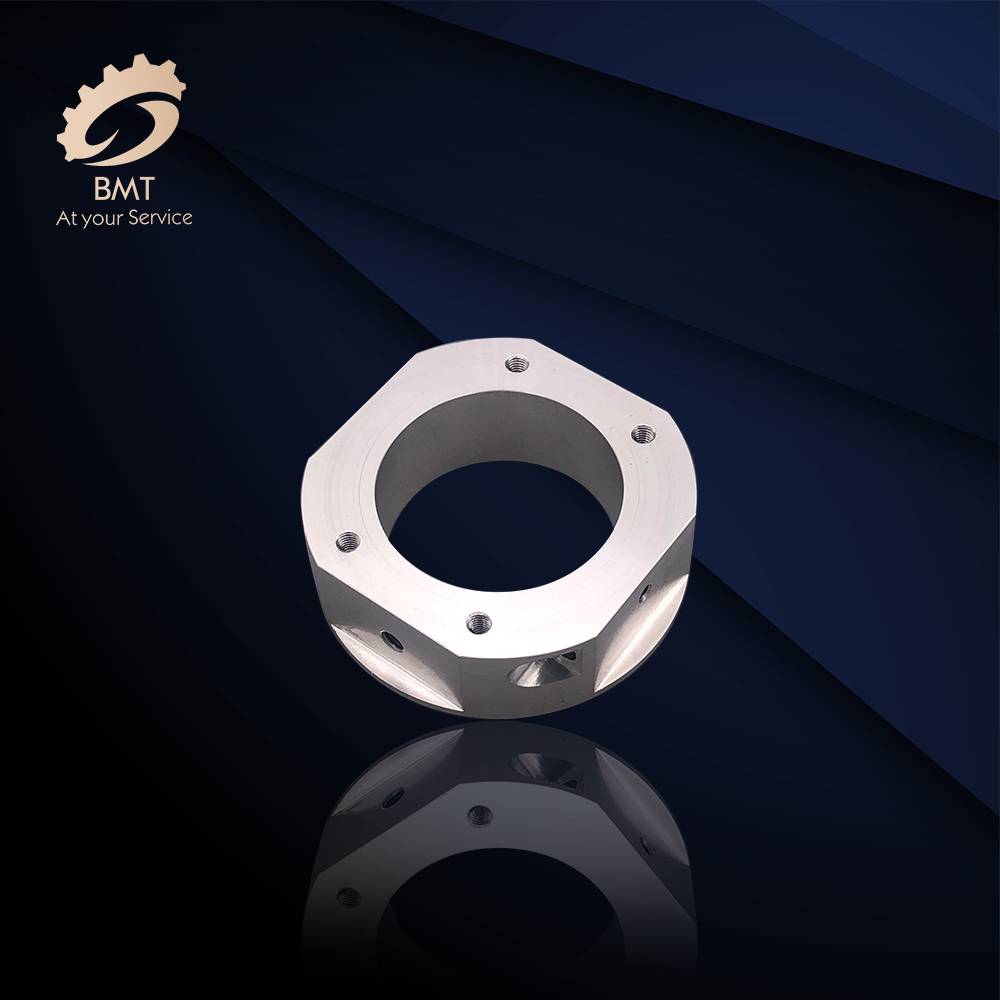

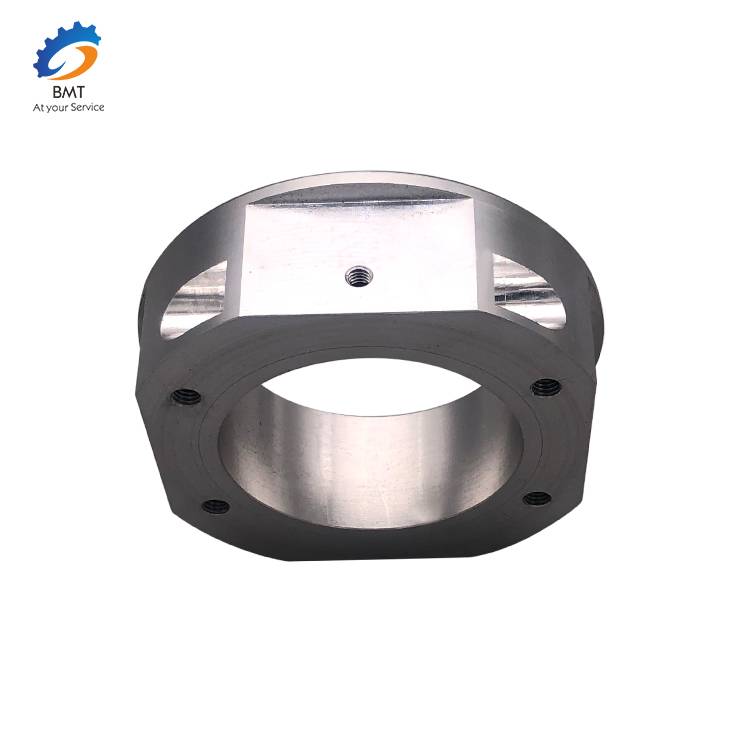

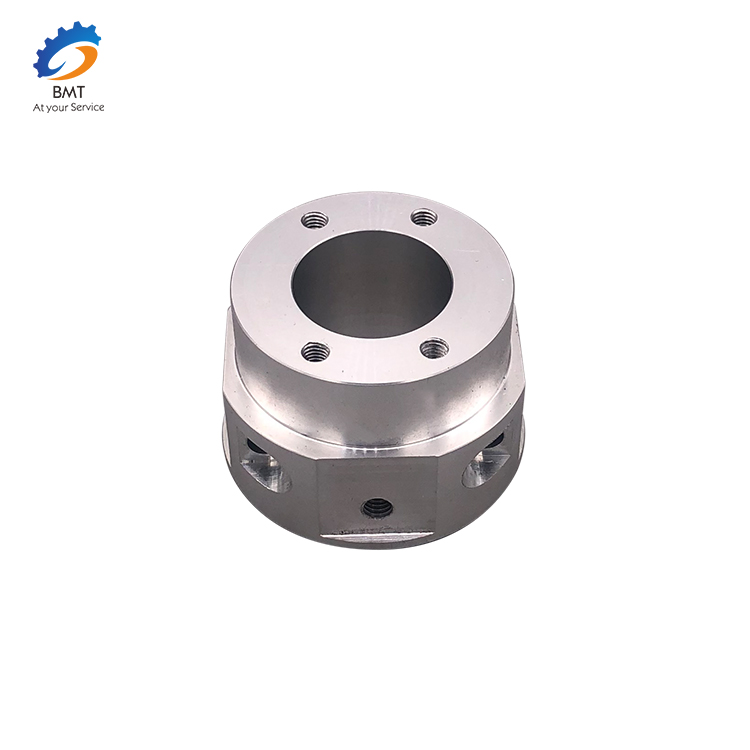

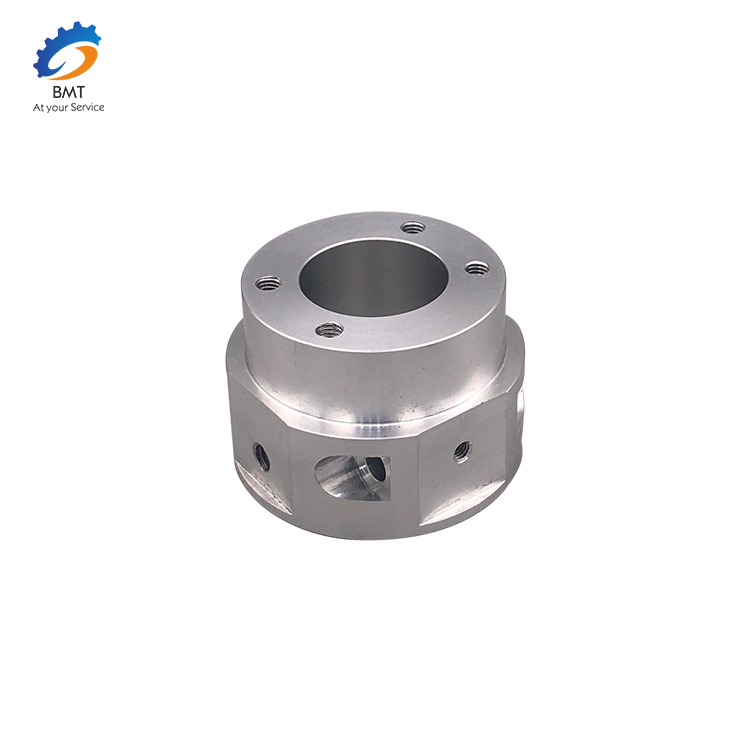

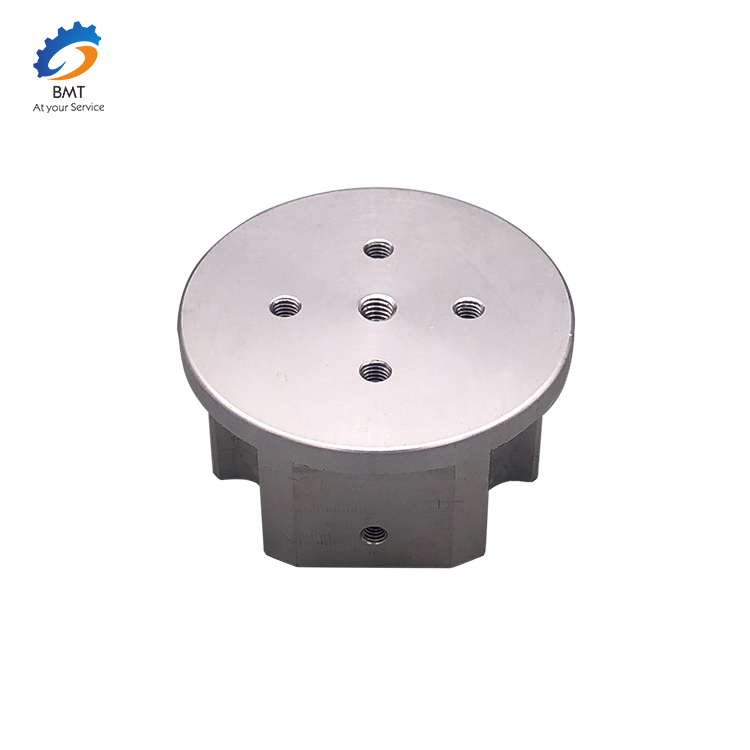

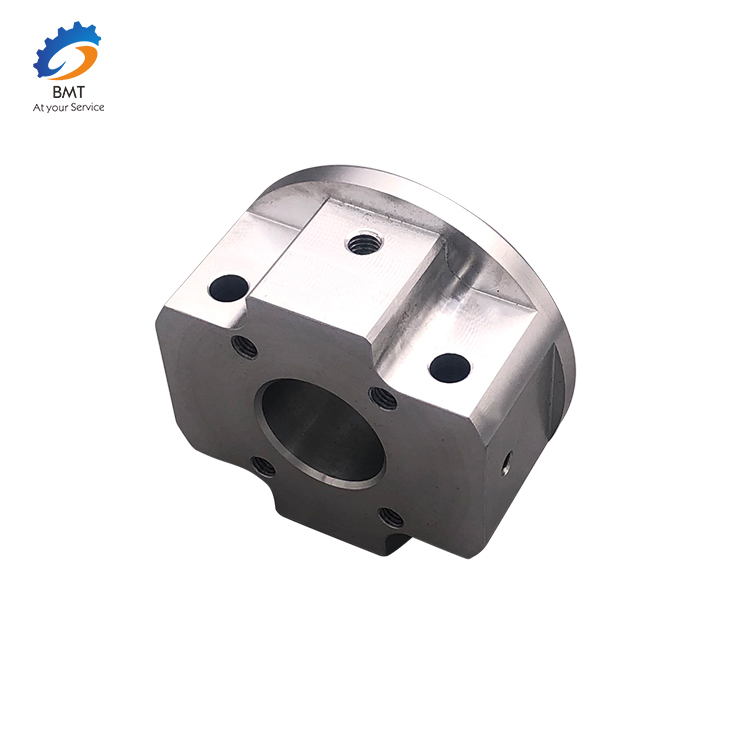

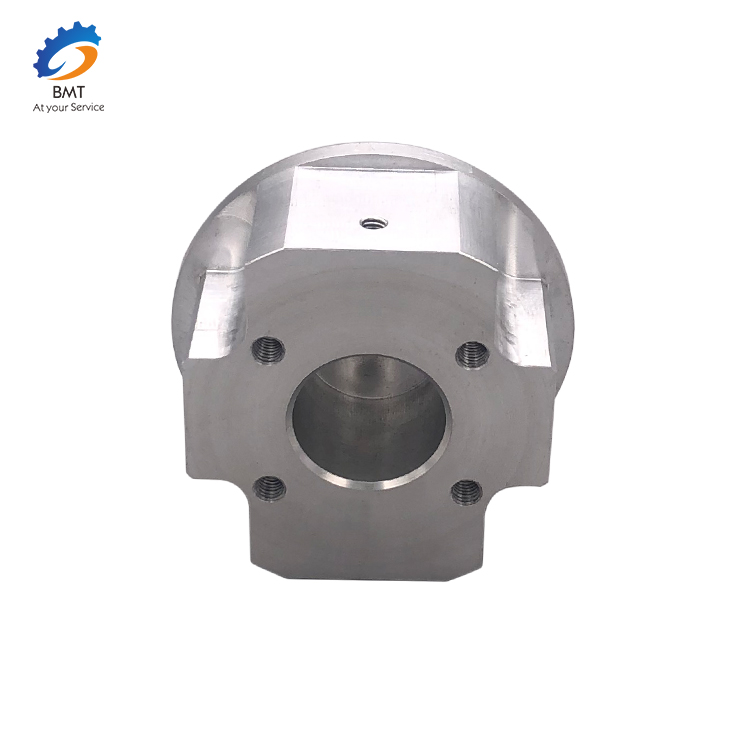

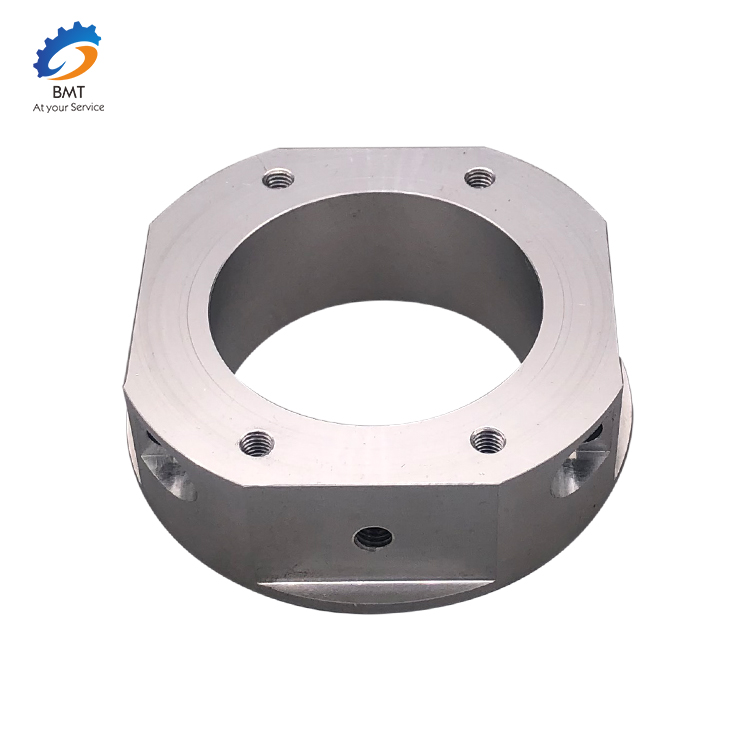

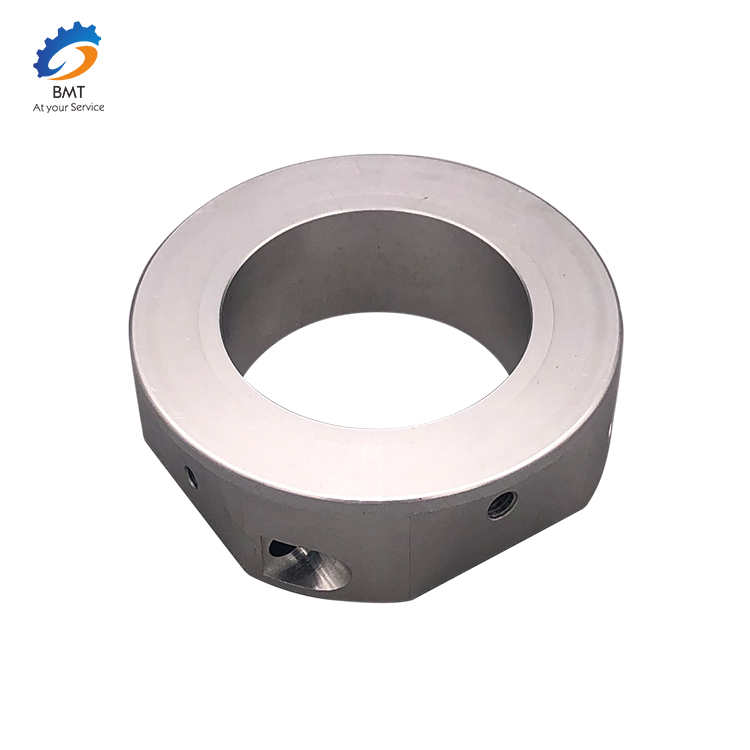

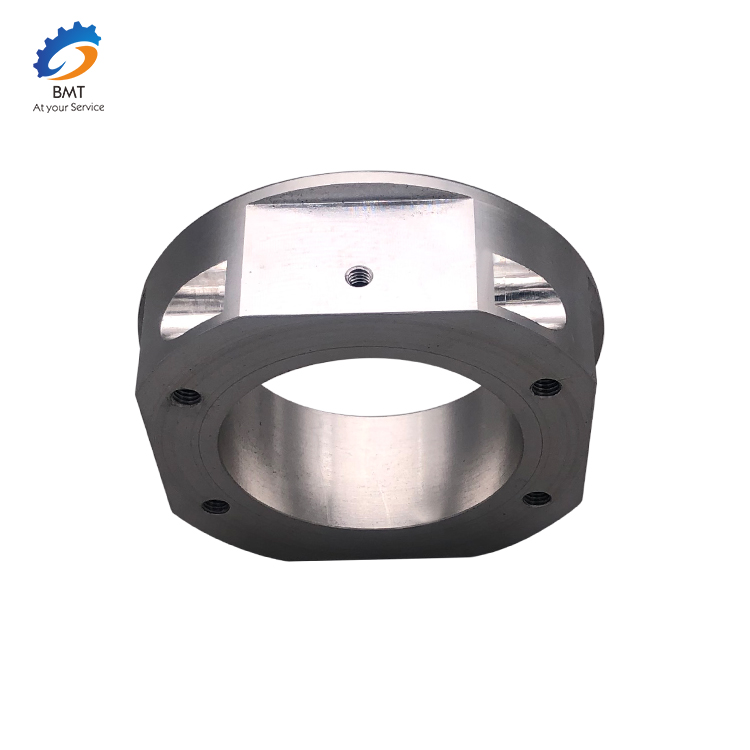

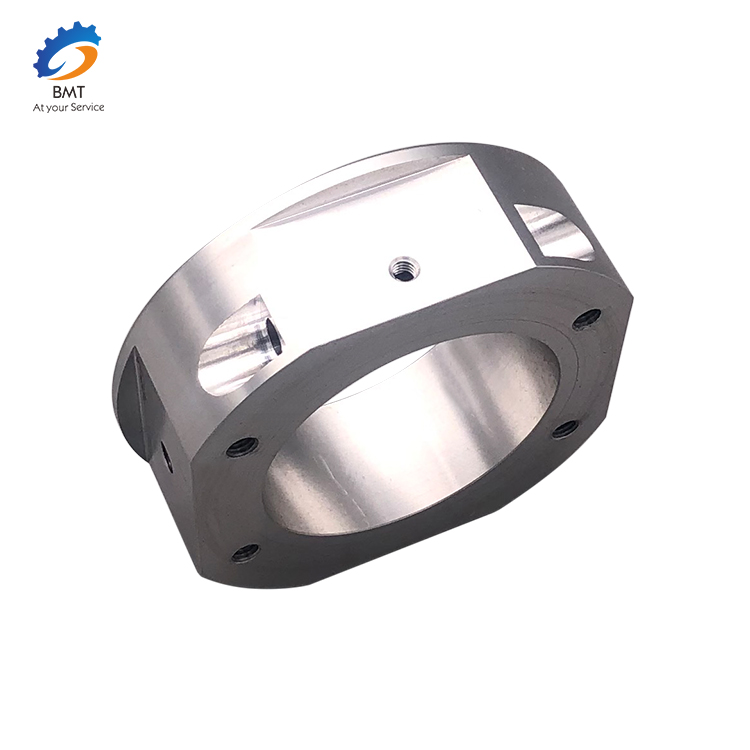

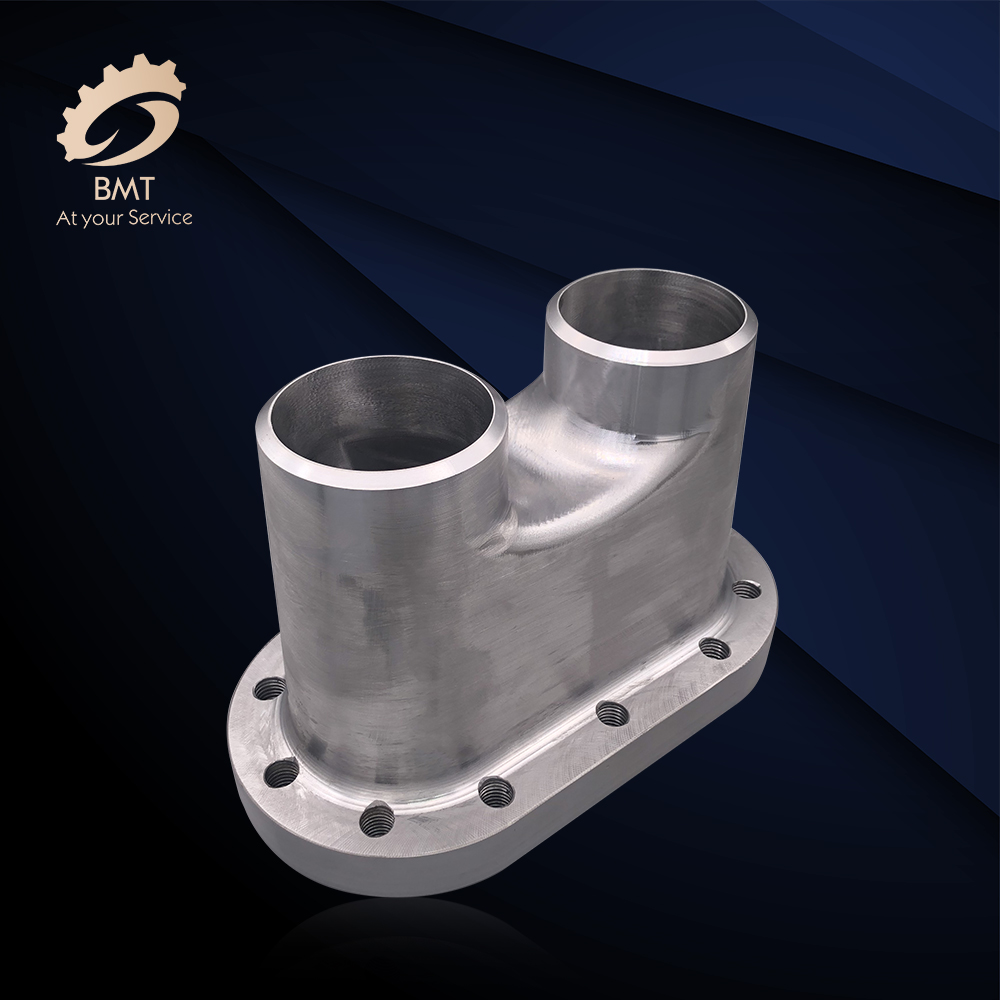

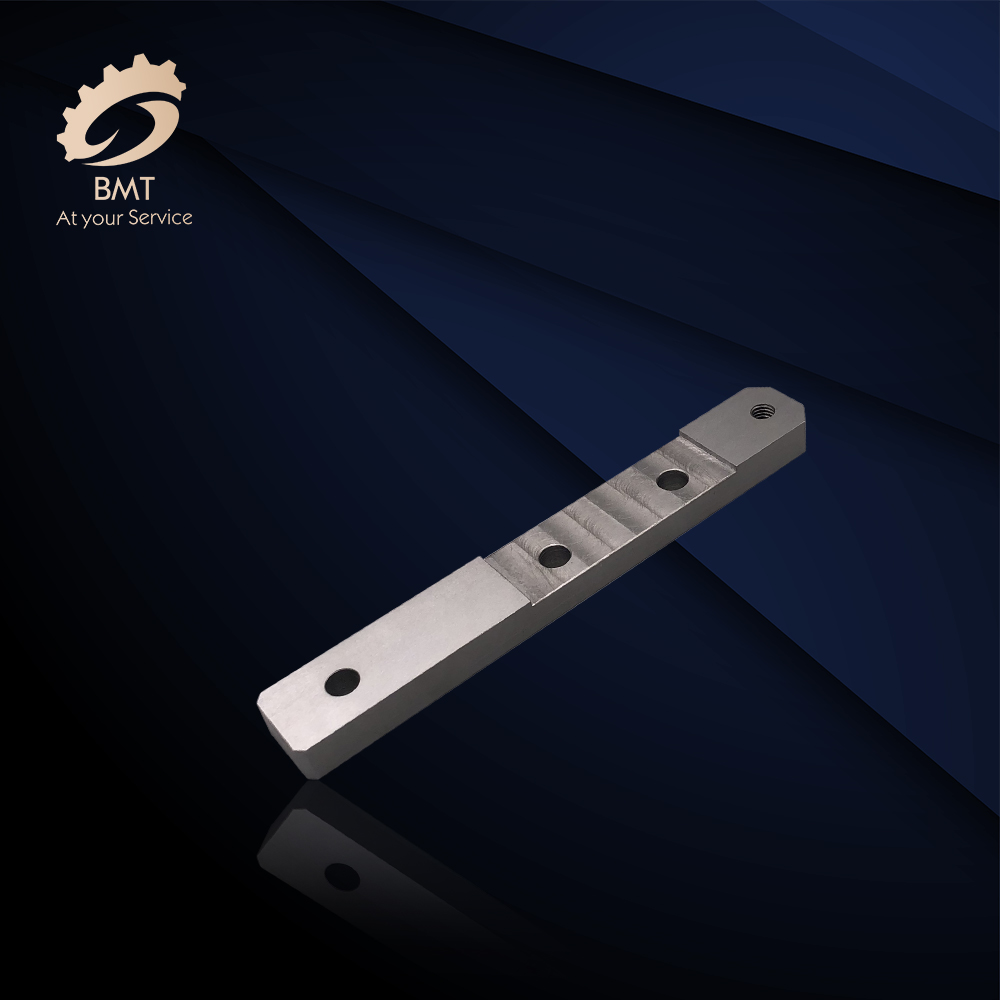

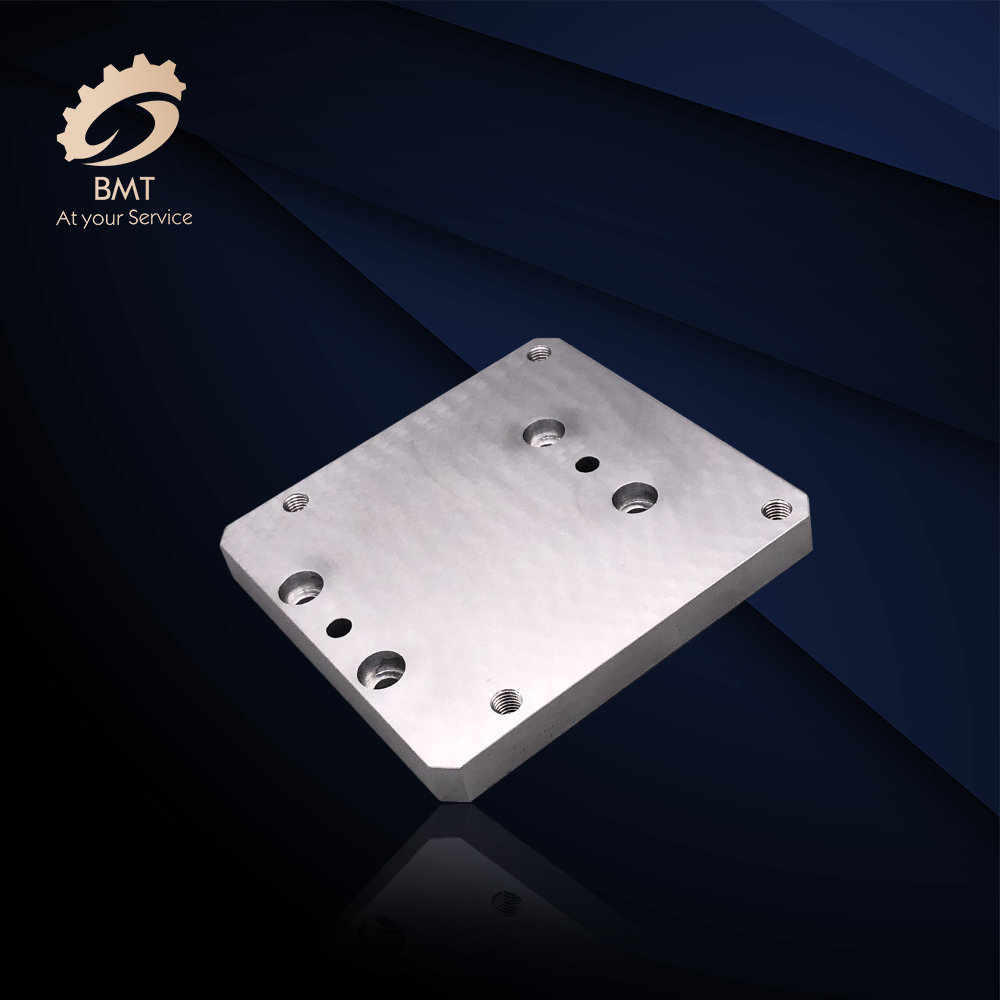

Our Precision CNC Machining Services

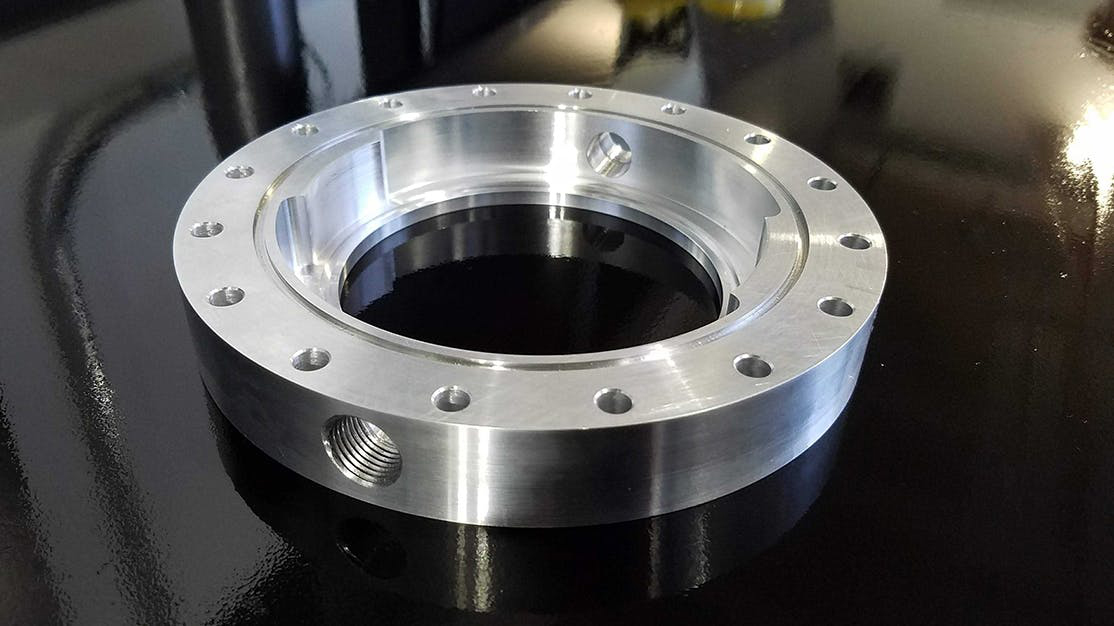

Precision machining is often used for parts that require a close tolerance. A professional engineer can manufacture complex parts with precise specifications, using a CNC controlled machine or a specialized lathe. Most machining today is completed with CNC machines and AutoCAD software, and may also use CAM programs. Most designs rely on CAD/CAM programs.

It is also employs on a wide variety of metals including stainless/carbon steel, aluminum, and brass as well as other materials like plastics. Depending on the raw material, various machines can be used. An engineer may need to use lathes, drill presses, milling machines, and high-speed robotics to remove material from the workpiece.

Product Description

BMT is proud to work with a selection of highly trusted, rigorously chosen customers. Each customer requests to offer the highest quality CNC Machined parts. By maintaining close relationships with our clients, BMT is able to offer exceptional levels of quality.

BMT commits to delivering Quality Assured CNC Machined Parts on time. It is one of the many reasons why our clients trust us with their manufacturing needs.

Trust us to deliver your CNC Machining Project on time, to specification and at a competitive price.