we can easily provide top quality solutions, competitive value and best client company. Our destination is “You come here with difficulty and we provide you a smile to take away” for Short Lead Time for China Factory Customized Metal Steel CNC Lathe Machining Parts, If you are interested within our products and solutions, you should come to feel absolutely free to ship us your inquiry. We sincerely hope to ascertain win-win company relationships with you.

we can easily provide top quality solutions, competitive value and best client company. Our destination is “You come here with difficulty and we provide you a smile to take away” for China Machining Part, CNC Lathe Machine, Wide selection and fast delivery for you personally! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

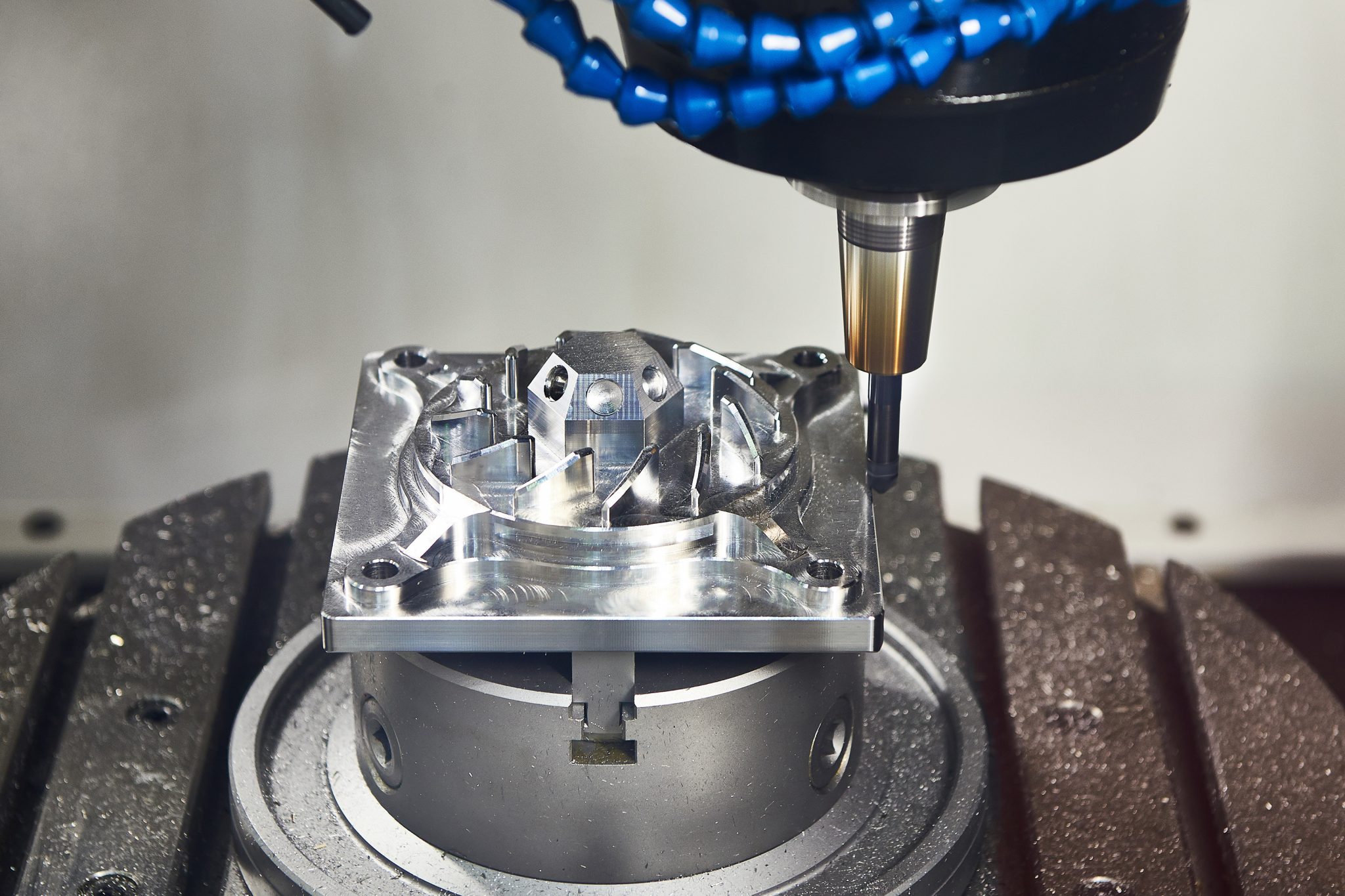

China Top CNC Milling Parts Manufacturer & Factory

What Is CNC Drilling & How CNC Drilling Works

Custom CNC Milling Service

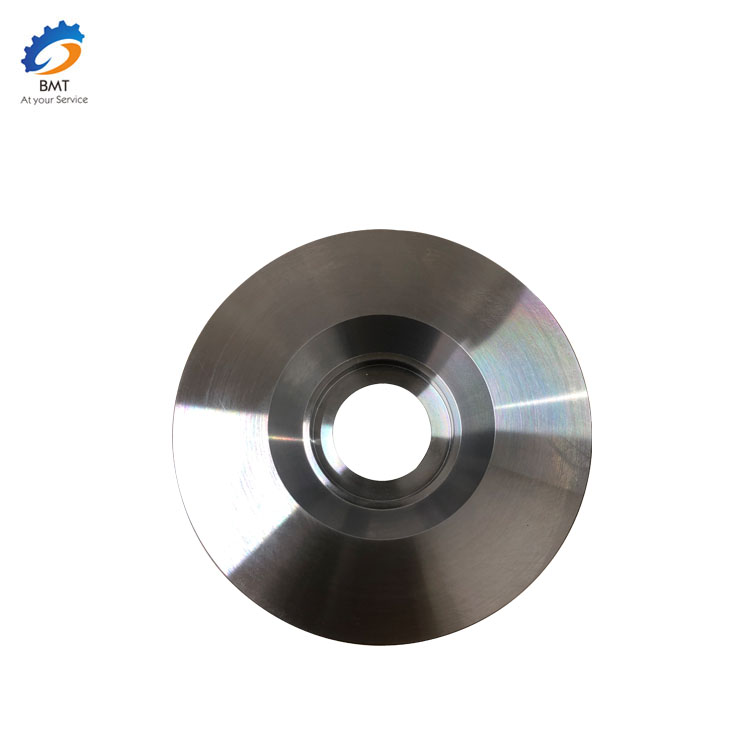

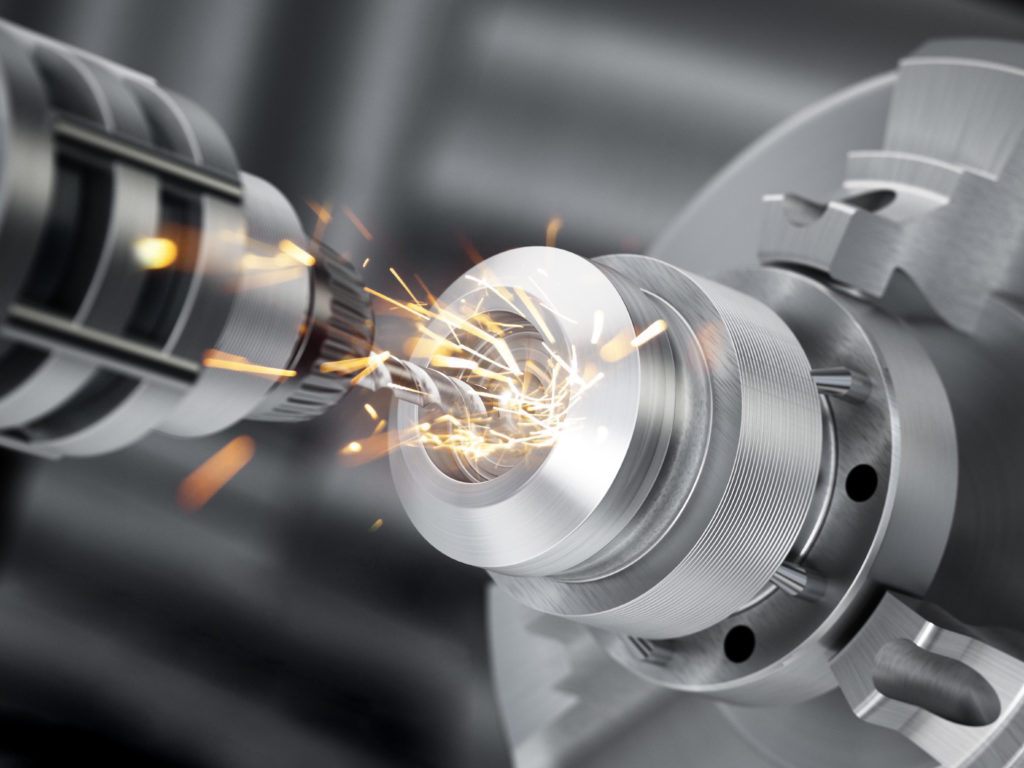

Cnc Surface Finishing Service

Metal finishing or metal finishes, it is the process of utilizing different techniques to alter the surface of an object, for improving the appearance and properties like corrosion resistance, tarnish resistance, chemical resistance, wear resistance, and hardness, modifying electrical conductivity, removing burrs or applying specific colors to the machined components.

It usually through adding a layer of metal or non-metal coating on the exterior of a metallic workpiece, which can also clean the part at the same time. The metal surface finishing services commonly applied on various CNC machining parts made of aluminum, stainless steel, brass and more materials.

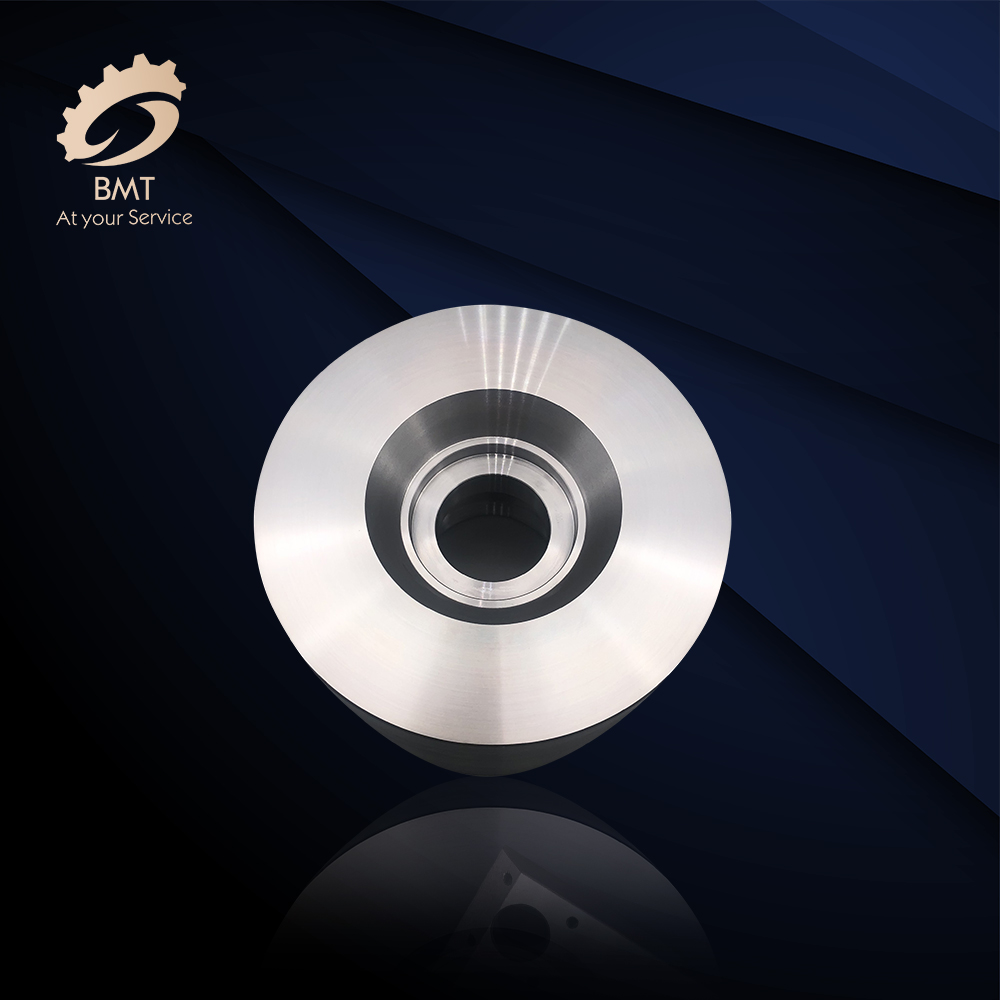

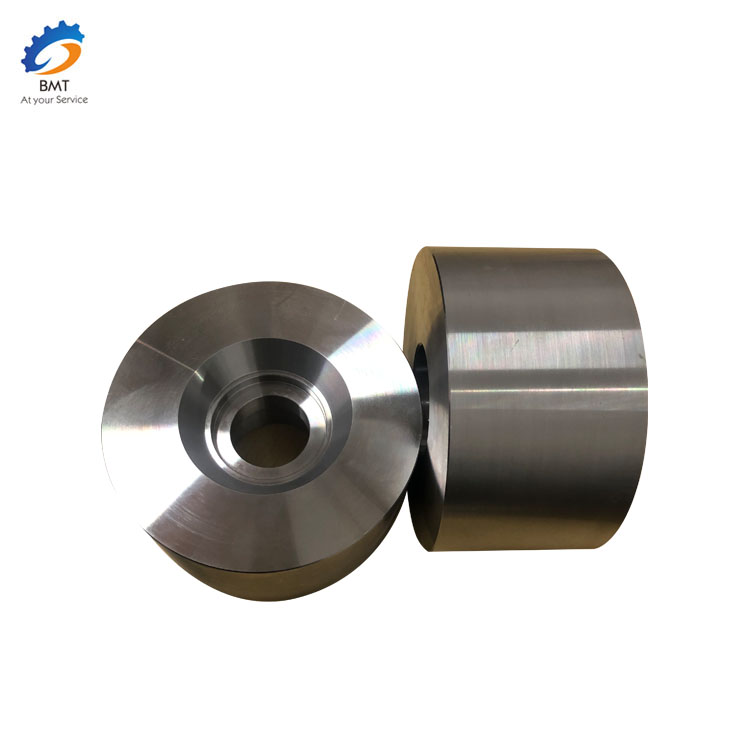

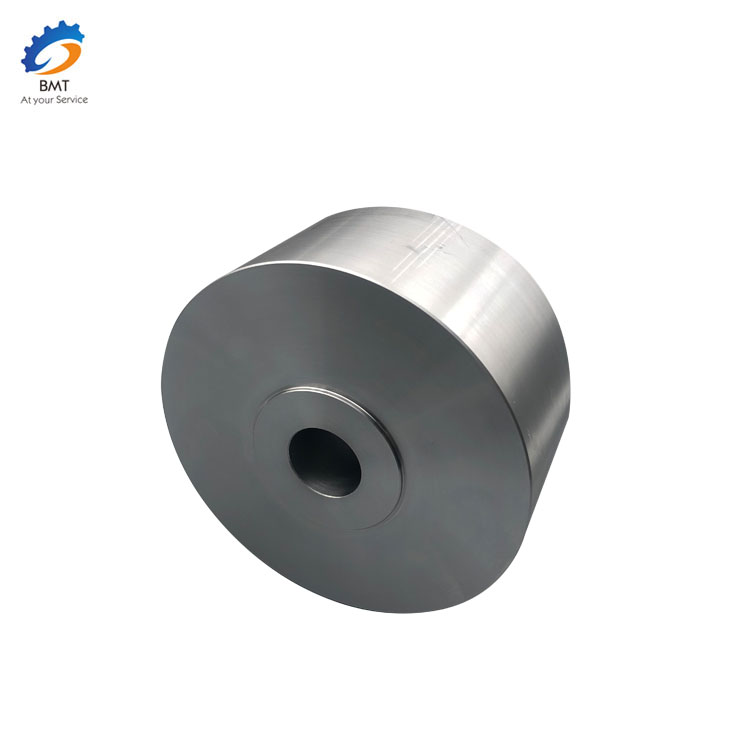

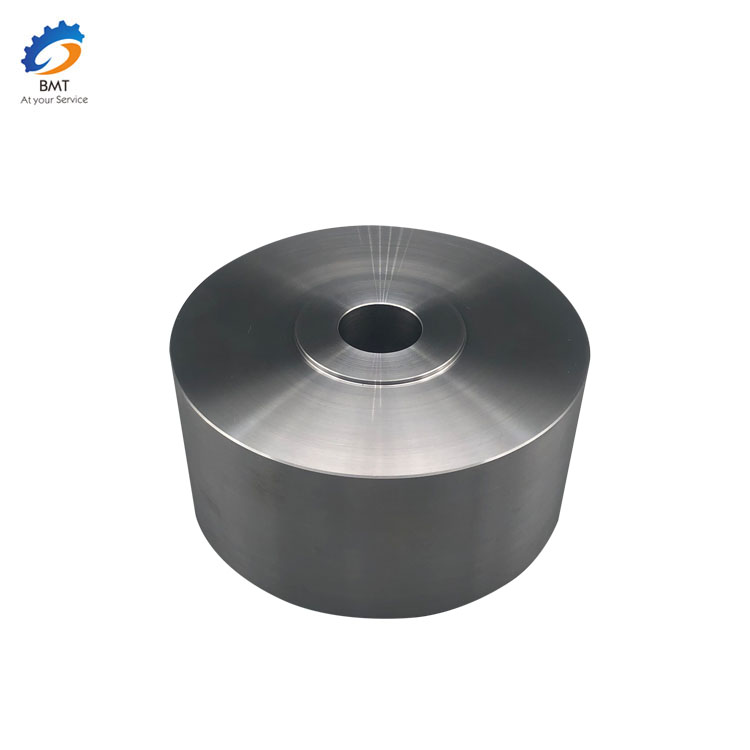

Custom CNC Turning Lathe Services

we can easily provide top quality solutions, competitive value and best client company. Our destination is “You come here with difficulty and we provide you a smile to take away” for Short Lead Time for China Factory Customized Metal Steel CNC Lathe Machining Parts, If you are interested within our products and solutions, you should come to feel absolutely free to ship us your inquiry. We sincerely hope to ascertain win-win company relationships with you.

Short Lead Time for China Machining Part, CNC Lathe Machine, Wide selection and fast delivery for you personally! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!