Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for Factory Cheap China Custom High Precision CNC Machining Service Aluminum Parts Milling with Anodizing, At present, corporation name has much more than 4000 kinds of products and gained very good status and big shares on current market domestic and abroad.

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for Auto Parts, China CNC Milling, Today, We are with great passion and sincerity to further fulfill our global customers’ needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Product Description

Precision machining can bring any manufacturing process to the next level. It can work wonders for operational efficiency, minimize turnaround time, and cut production cost. Who knows this better than one of China’s major CNC Turning and Milling components manufacturers with 15 years of experience under its belt? BMT has been providing exceptional precision parts for industries ever since.

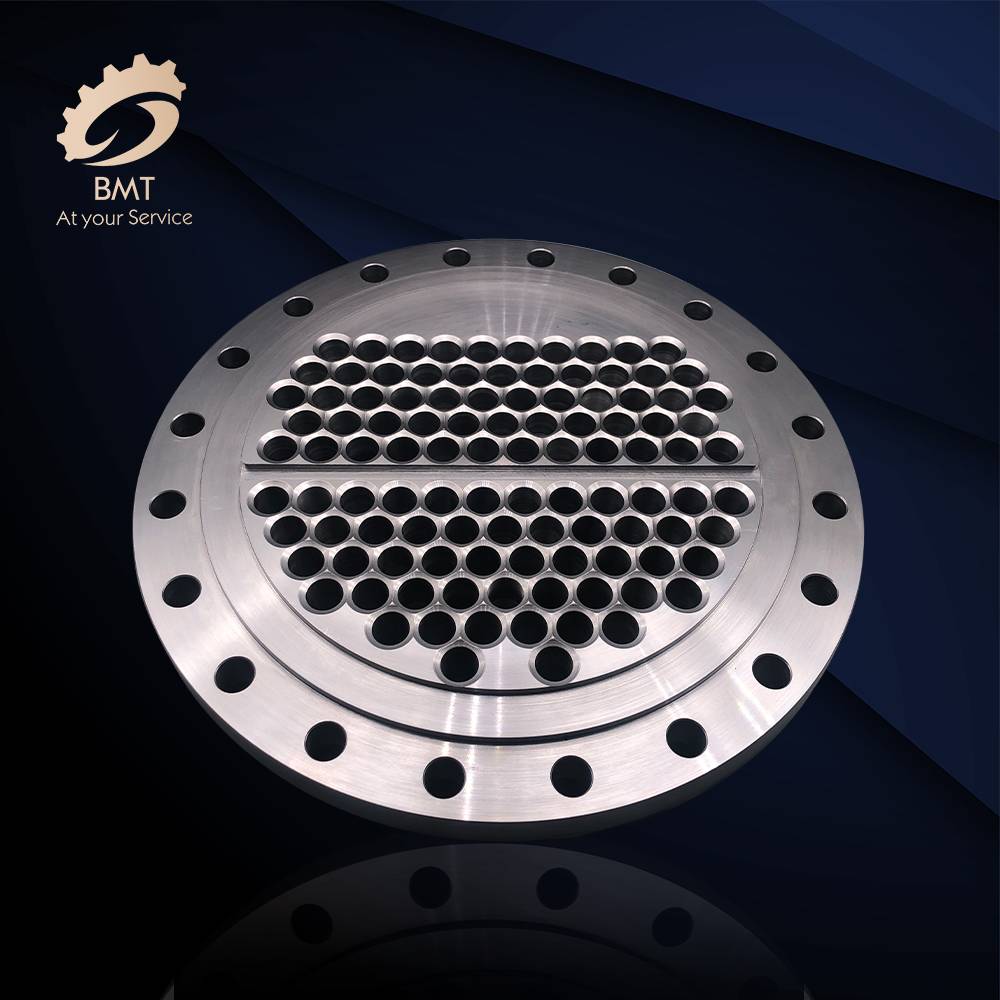

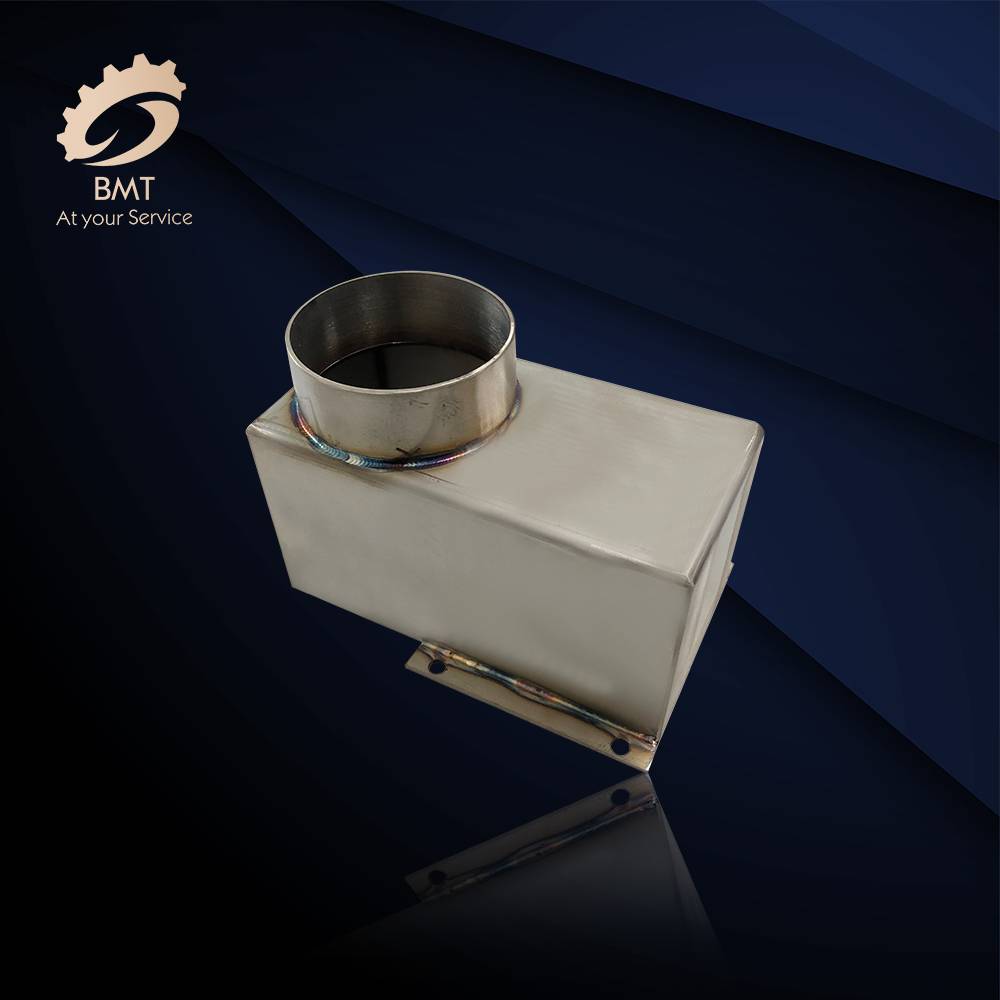

Our CNC manufacturing capabilities are backed up by state-of-the-art equipment, including 3-axis and 4-axis machines, conventional lathes, bandsaw cutting machines, milling tools, laser engravers, radial drilling machine, WEDM, etc. What does that mean to you? BMT has everything it takes to supply you with whatever precision items you need – from milling and turning components to automatic machining and sheet metal and stamping ones.

Product Description

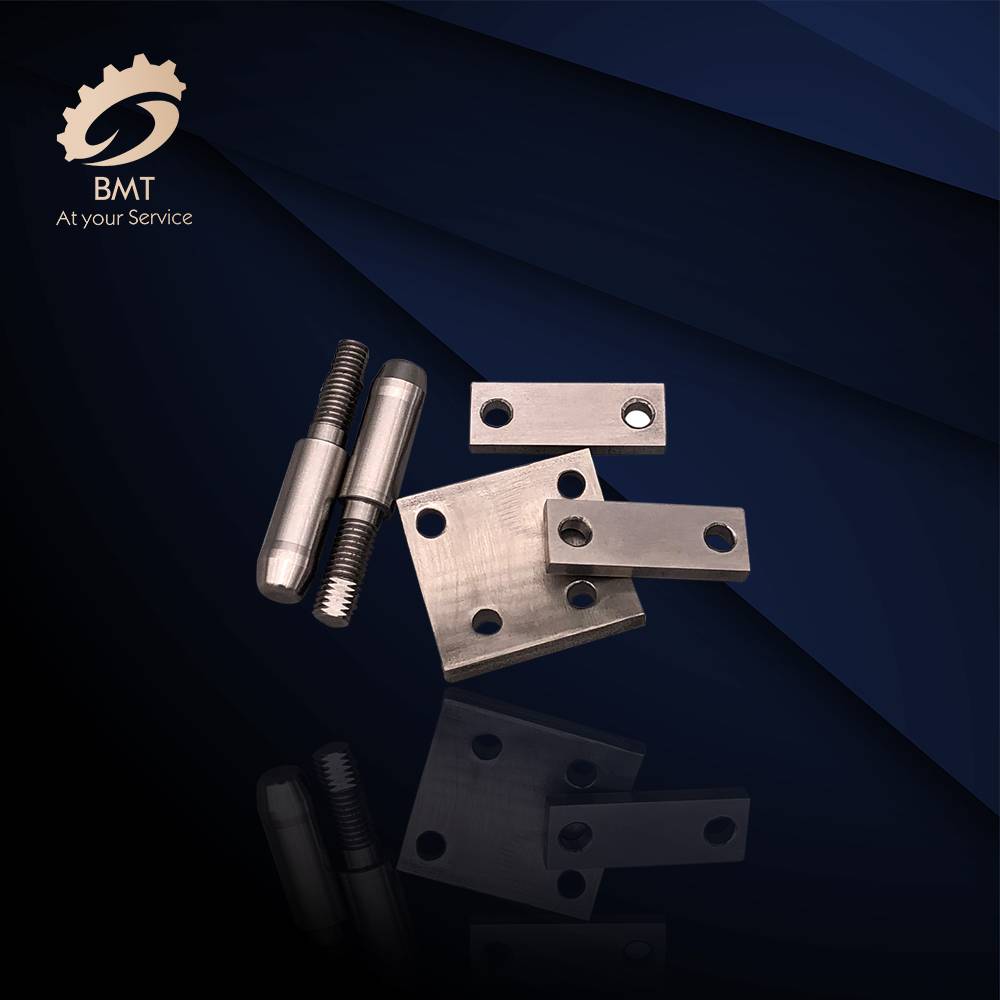

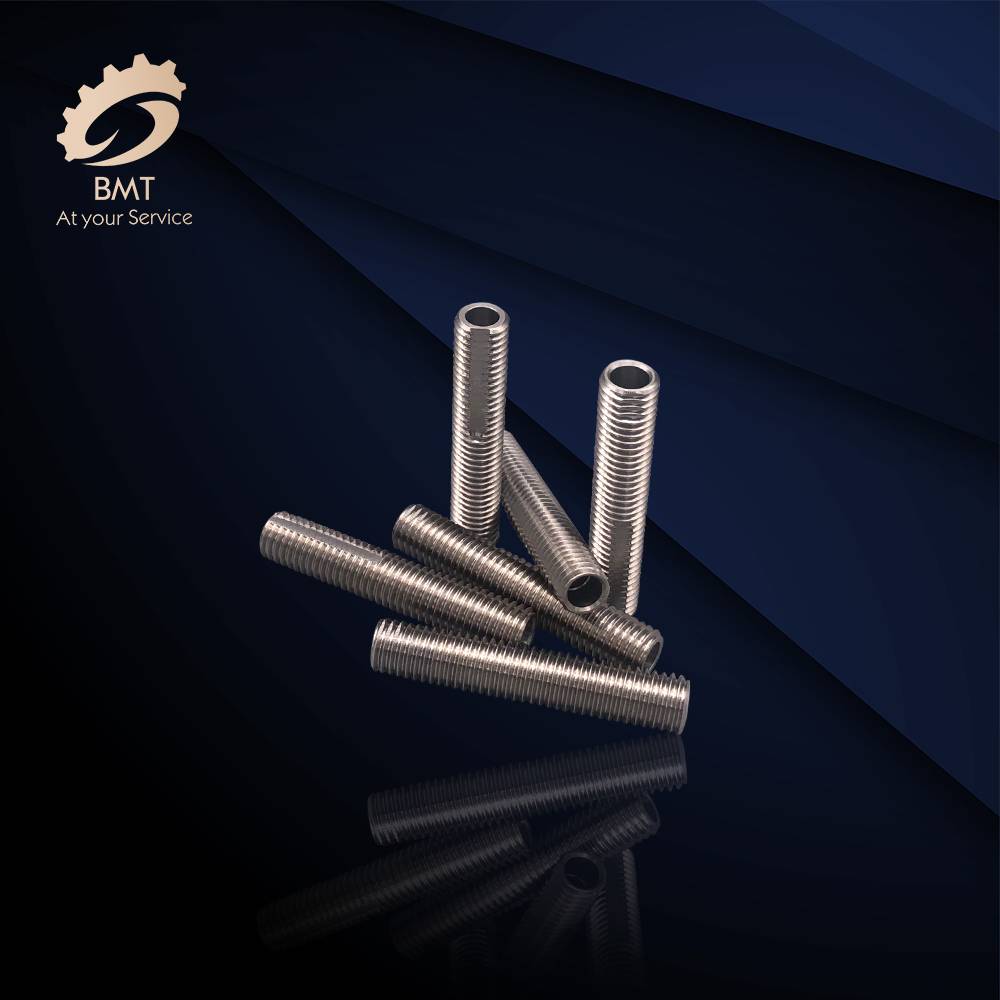

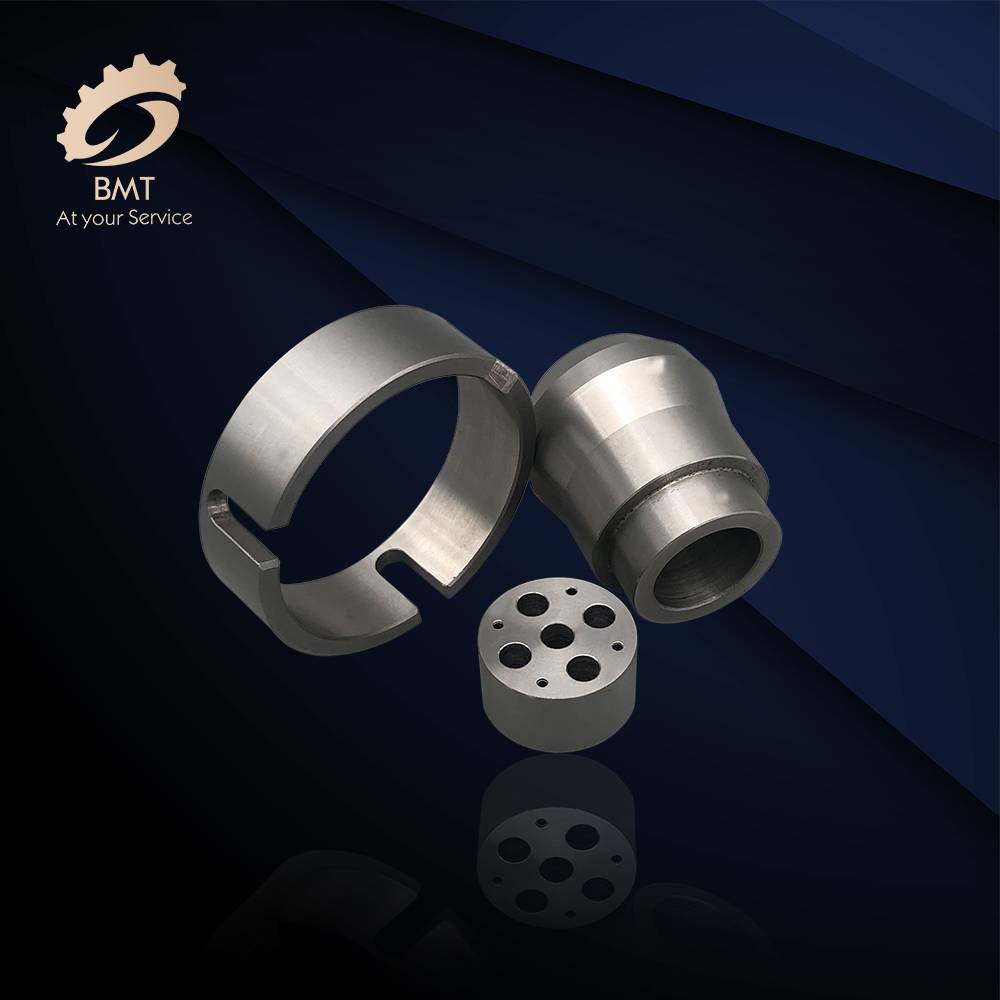

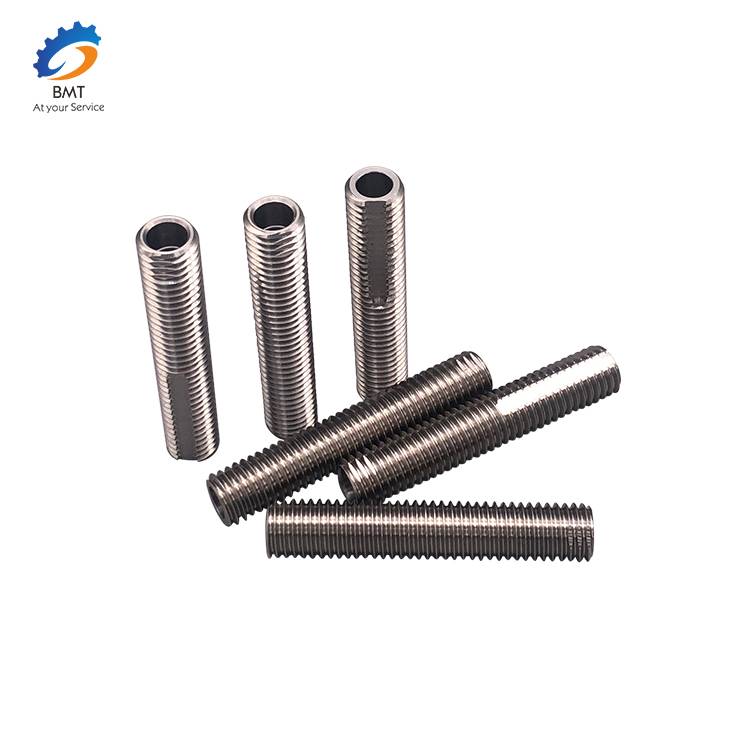

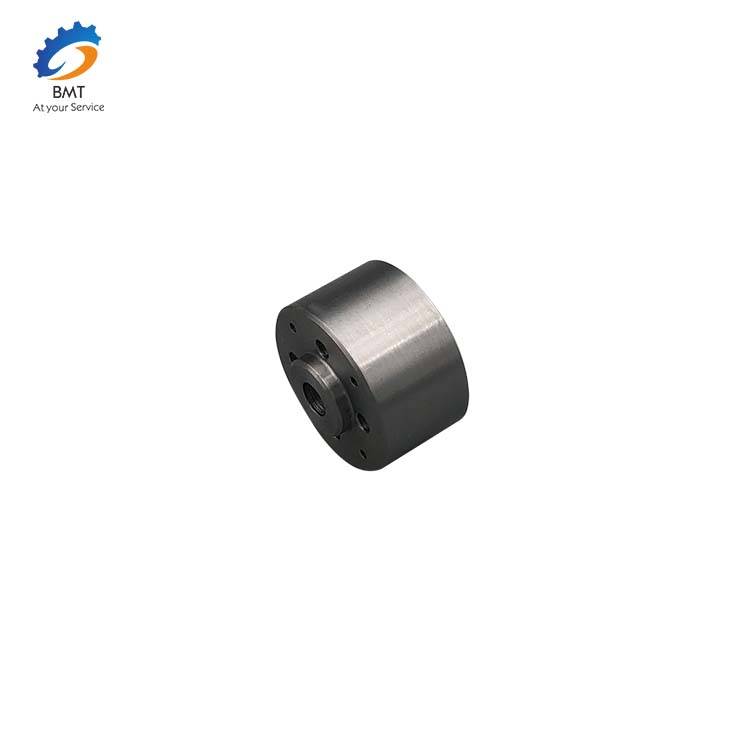

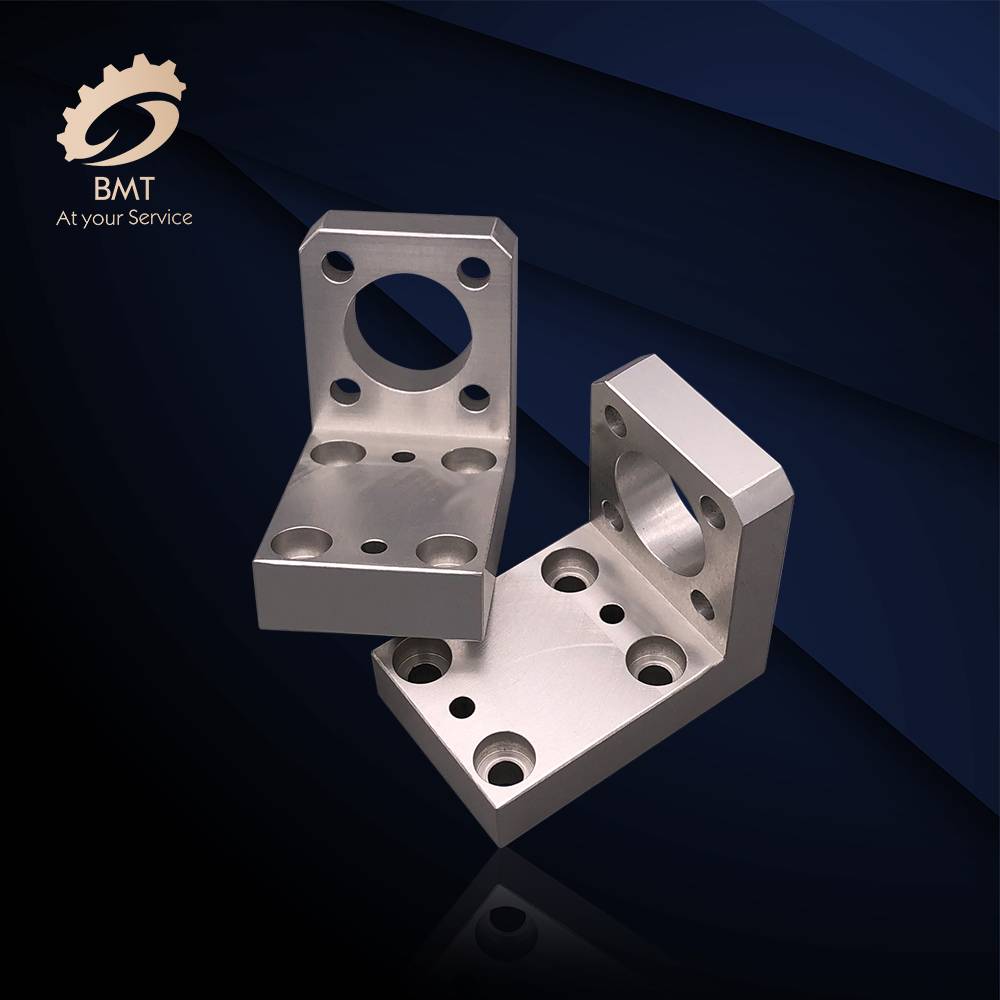

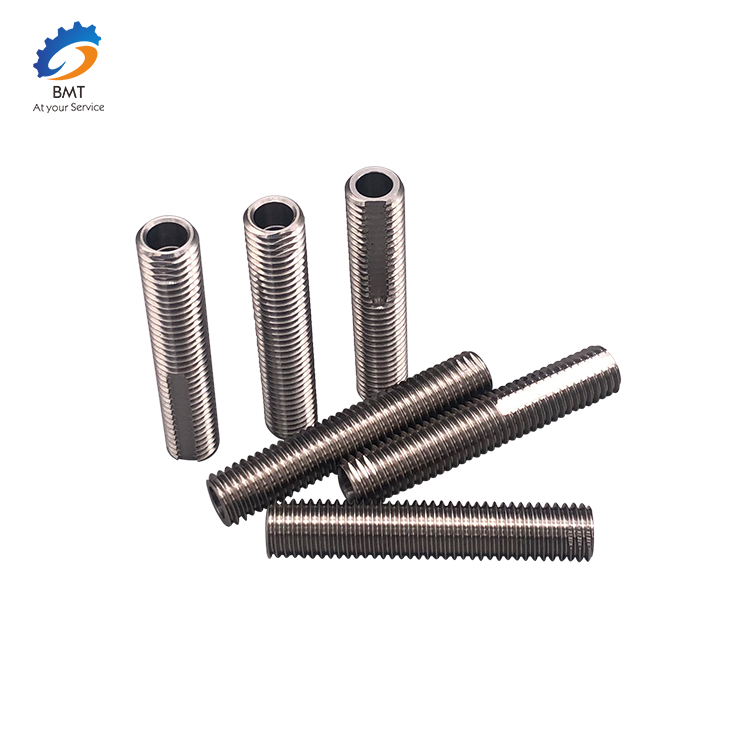

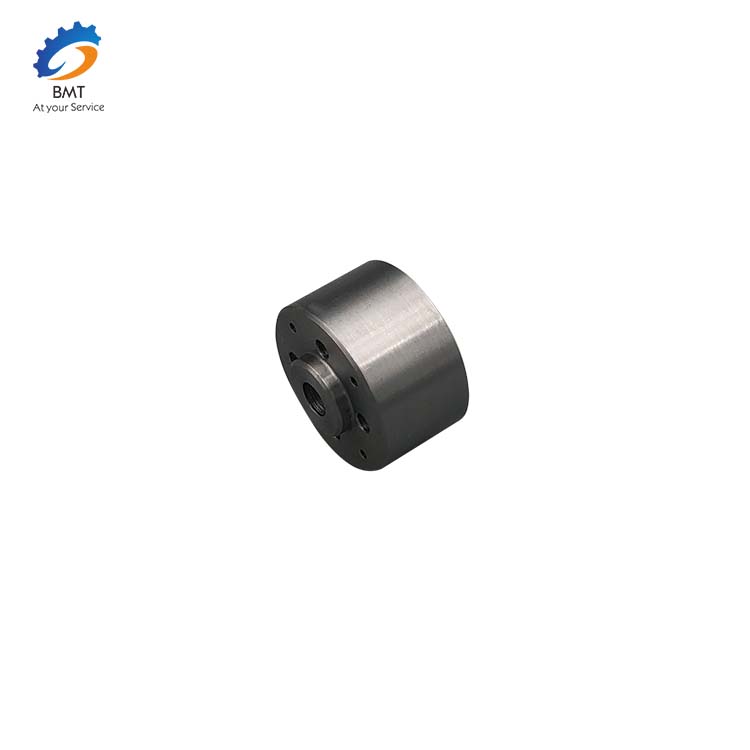

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Precision Machining Parts

Why Choose Our CNC Machined Parts?

With us, you can benefit from much more than just a varied assortment of precision items. As one of the top CNC machining parts suppliers, we are in a position to provide you with professional related to:

Quality

Our products can be designed to comply with ROHS, REACH, ASTM, ISO, and other international standards.

Durability

All of our CNC parts undergo a range of control procedures to ensure that they can withstand regular use. With us, you can take advantage of precision machining while saving a lot.

Service

Do you need help with installing some components or want to order custom machined parts? Contact us at your convenience.

Although our main production facility is based in Dalian, China, we supply CNC machining parts outside China, too. The coverage of BMT extends far beyond local markets, and we’ve successfully made a name for ourselves in the USA, Germany, Italy, Saudi Arabic and Russia. The world’s leading manufacturer trust us as we always meet their needs.

If you’re engaged in one of these or any other industry that relies on the use of CNC technologies, rest assured that BMT can help you take your production up a notch. We work with a variety of materials, including stainless steel, aluminum, titanium, bronze, brass, etc. Let us know what your manufacturing processes call for, and we’ll supply you with that for a reasonable price.

For your convenience, you can find the much-needed CNC machined parts in a few clicks with the help of a search bar on our website. Feel free to send us emails or call us at any time. BMT—At Your Service!

CNC Machining

Computer numerical control machining is a computer-aided technique that can be used in conjunction with a broad range of equipment. It requires software and programming, usually in the G-code language, to guide a machining tool in shaping the workpiece according to preset parameters. As opposed to manually guided methods, CNC Machining is an automated process. Some of its benefits include:

High production cycles: Once the CNC machine has been properly coded, it usually needs minimal maintenance or downtime, allowing for a faster production rate.

Low manufacturing costs: Due to its turnover speed and low manual labor requirements, CNC machining can be a cost-efficient process, particularly for high-volume production runs.

Uniform production: CNC machining is typically precise and yields a high level of design consistency among its products.

Precision Machining

Any machining process that requires small cutting tolerances or finest surface finishes may be considered a form of precision machining. Like CNC machining, precision machining can be applied to a wide number of fabrication methods and tools. Factors such as stiffness, damping, and geometric accuracy can influence the exactness of a precision tool’s cut. Motion control and the machine’s ability to respond at rapid feed rates are also important in precision machining applications.