We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Hot Sale for China OEM Customized High-Pressure Die-Casting Precision Machining Supplier Metal Magnesium-Zinc-Aluminum Alloy Die-Casting Parts, Sincerely hope to build long lasting company relationships with you and we’re going to do our best company in your case.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Aluminum Die Casting, China Die Casting, In the new century, we promote our enterprise spirit “United, diligent, high efficiency, innovation”, and stick to our policy”basing on quality, be enterprising, striking for first class brand”. We would take this golden opportunity to create bright future.

Custom Made CNC Machining Parts

Mechanical parts processing technology refers to the process of changing the dimensions or properties of the workpiece through a mechanical equipment. According to the difference in the way of processing, it can be divided into cutting and pressure processing.

Mechanical parts processing methods mainly include: turning, milling, planing, inserting, grinding, drilling, boring, punching, sawing and other methods. It can also include wire cutting, casting, forging, electro-corrosion, powder processing, electroplating, and heat treatment and so on.

1. Turning:

There are vertical lathe machine and horizontal lathe machine; new equipment has CNC lathe machine, mainly processing rotary body;

2. Milling:

There are vertical milling and horizontal milling; new equipment has CNC milling, also known as the CNC machining center, mainly process groove and shape plan area. Of course, it can also process camber with two axes or three axes CNC Machining Center.

3. Planing:

Mainly process shape plan area surface. Under normal circumstances, the surface roughness is not higher than milling machine;

4. Inserting:

It can be understood as a vertical planer, suitable for non-complete circular arc processing.

5. Grinding:

There are plane grinding, circular grinding, inner hole grinding, and tool grinding, etc. High precision surface processing, the workpiece surface roughness is particularly high;

6. Drilling:

Normally, it is holes processing.

7. Boring:

It is mainly boring hole through the boring tools or blade, as well as the processing of large diameter, high precision hole, and larger workpiece shape.

8. Punching:

It is mainly punching molding through punching machine, which can punch round or special-shaped hole.

9. Cutting and Sawing:

It is mainly cutting material through the sawing machine, often used in the blanking process.

Any machine is made up of many precise parts, without the machining parts, the machine is incomplete. That’s the reason why the machining parts play the most important role in mechanical industries.

With the development of automation, mechanical processing technology has also begun to automate the direction of continuous evolution, it must play an important role in the development of the future society, you know, the power of mechanical process is the development of the national economy. In BMT, we apply the technology very well, so as to provide the best machining parts to our customers. If anything needed, please contact us immediately.

Product Description

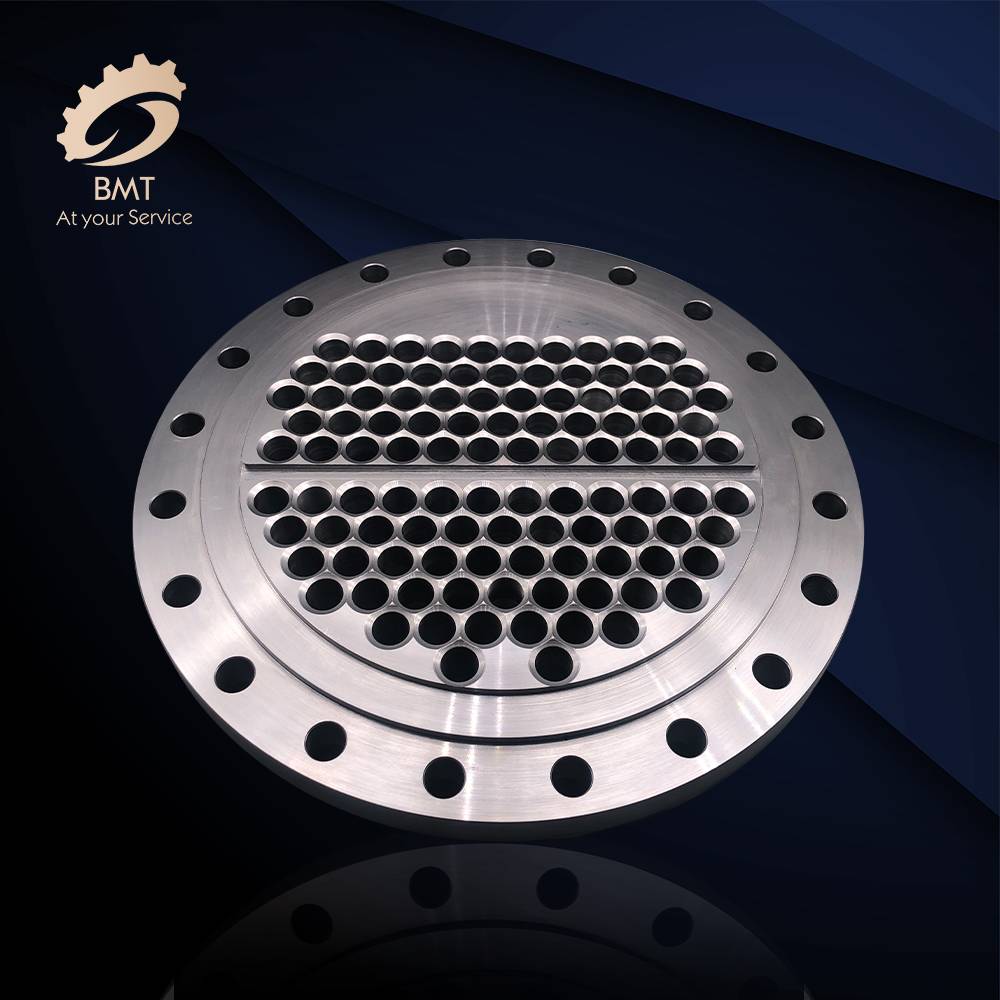

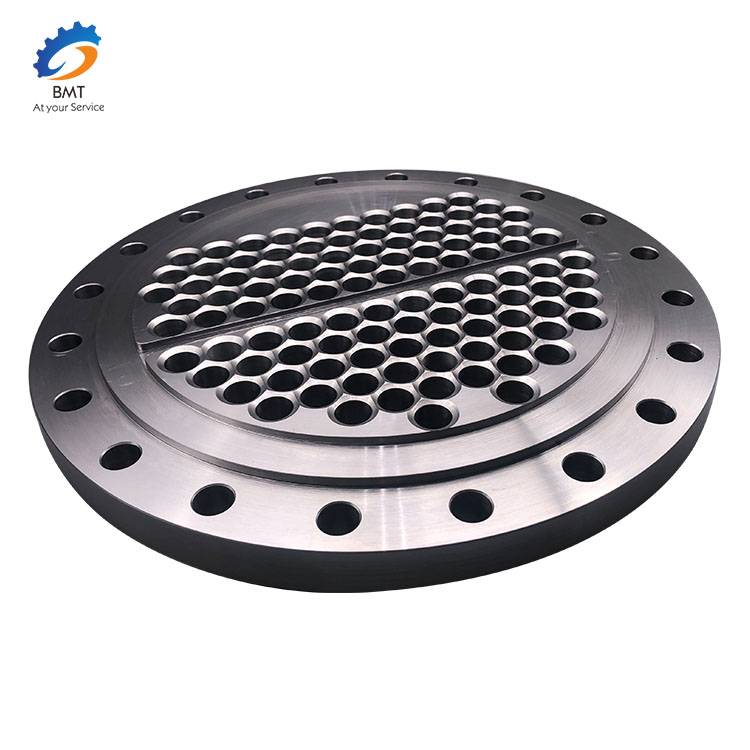

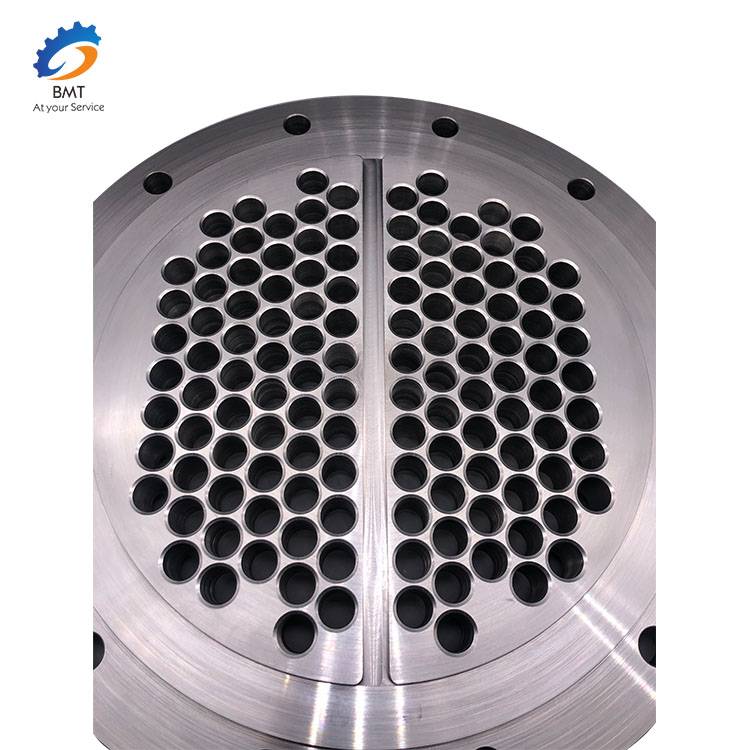

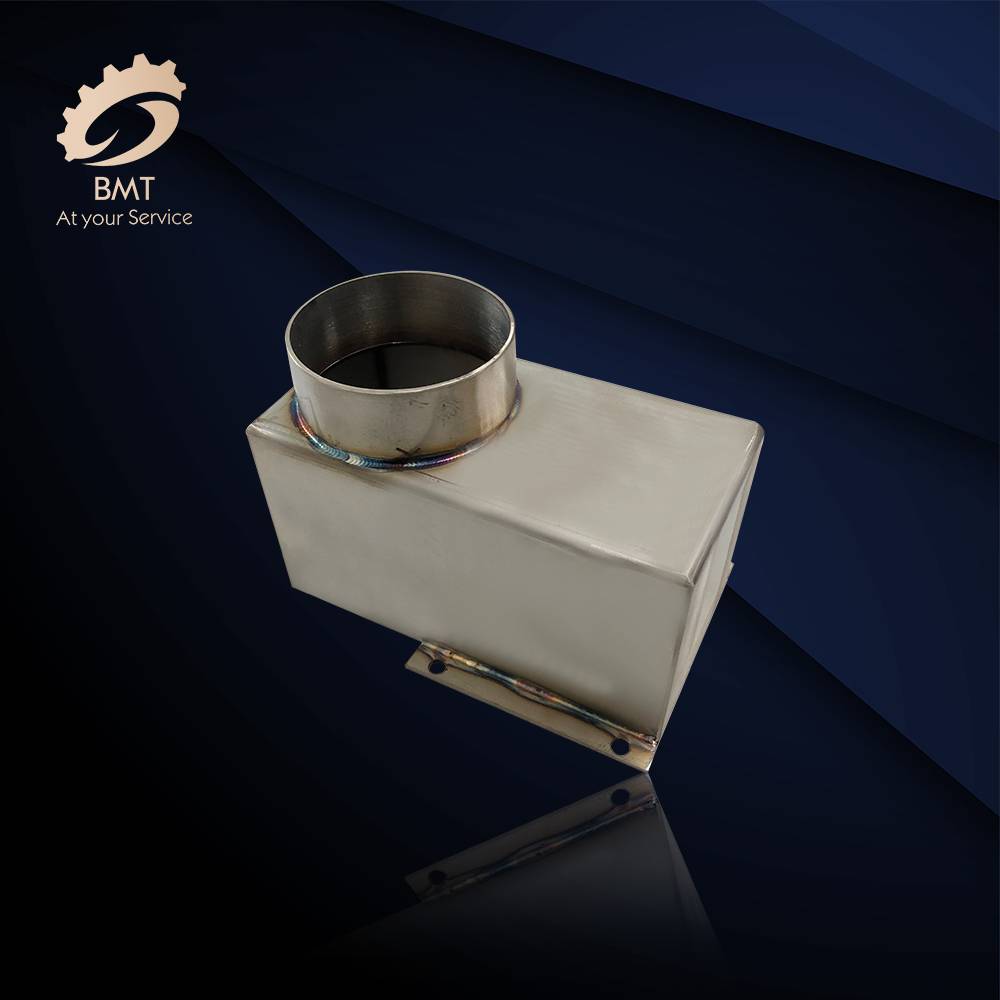

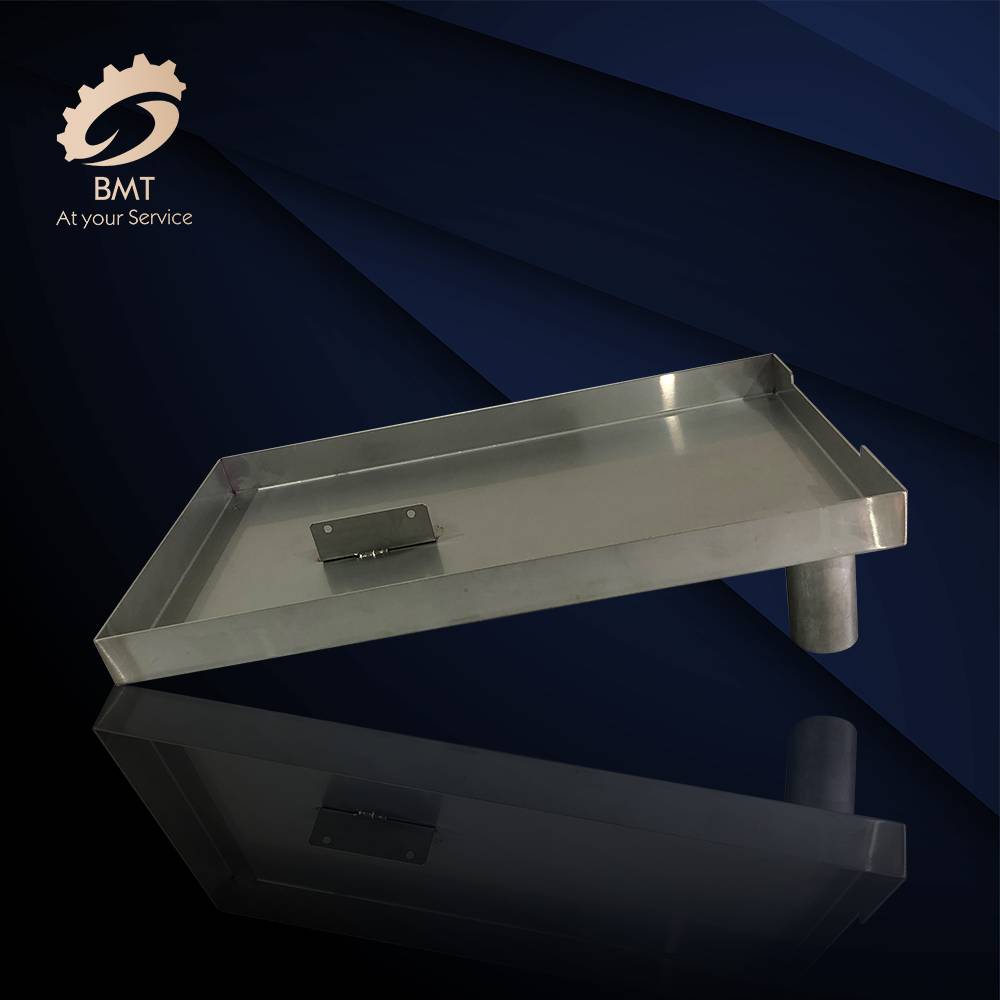

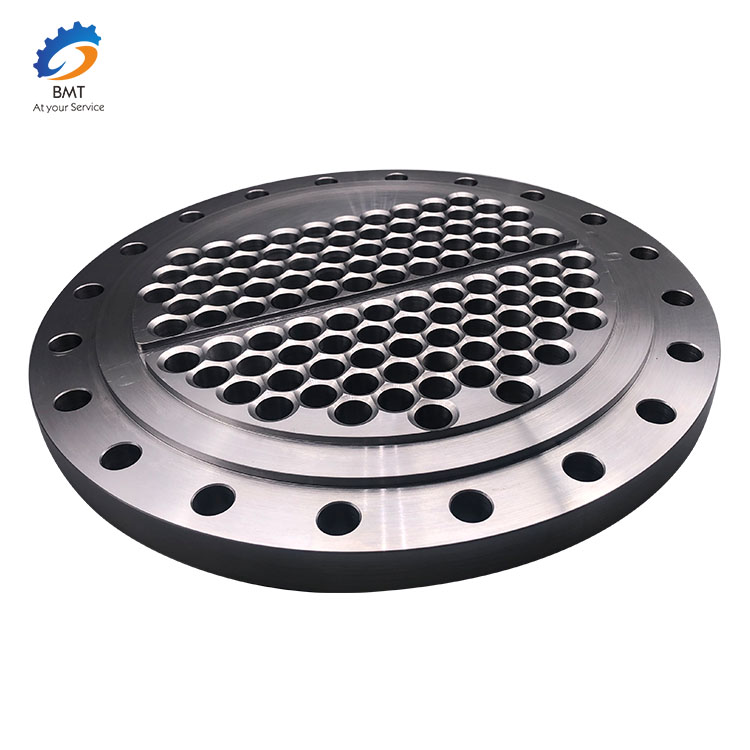

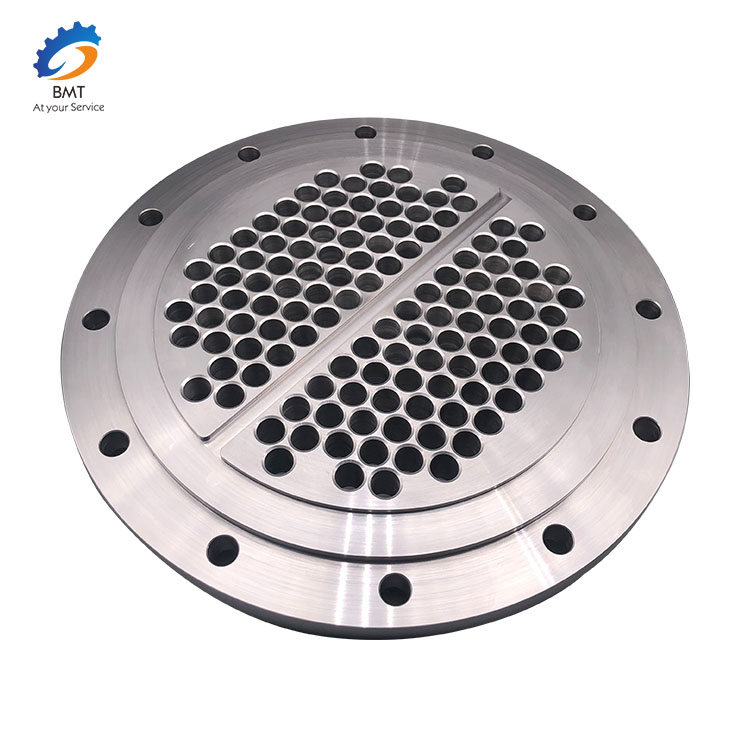

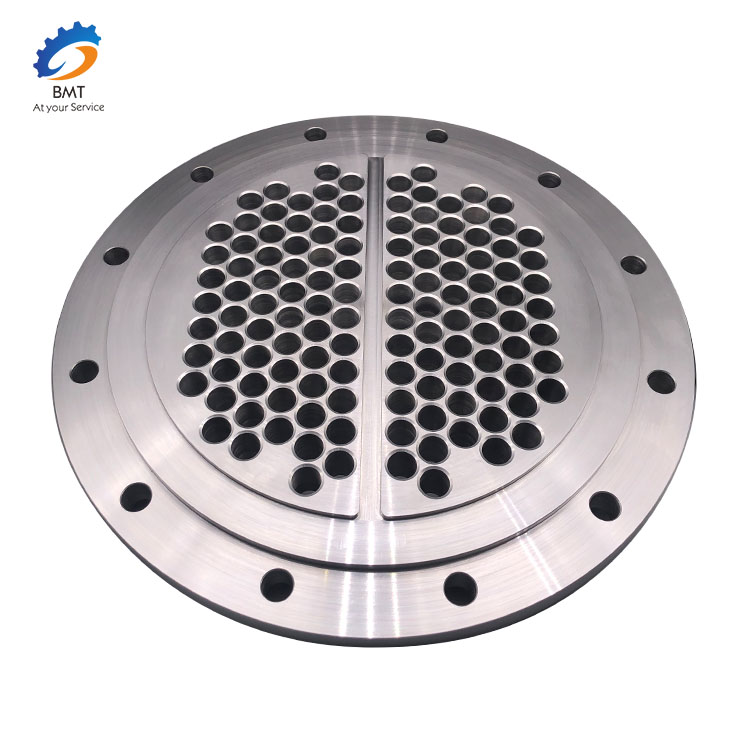

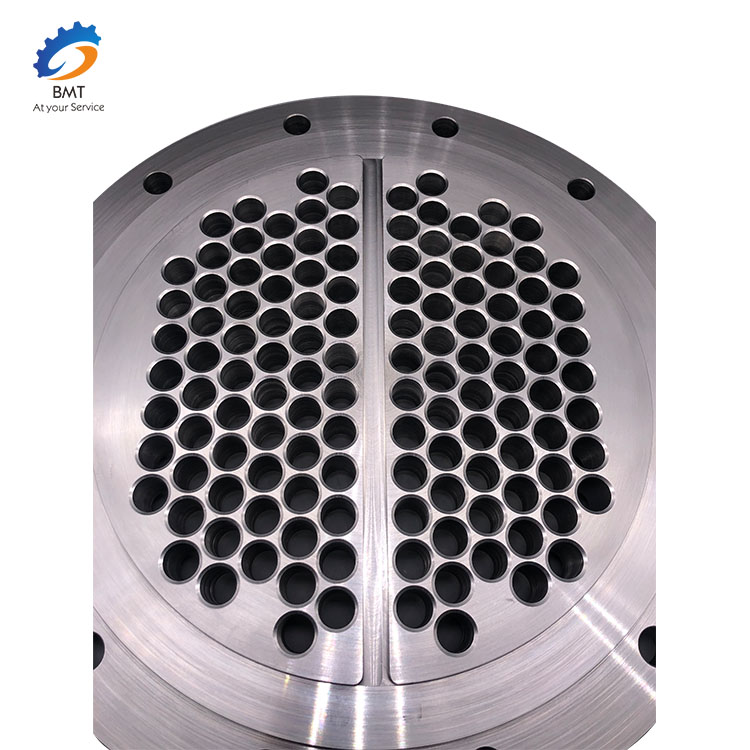

Plate tube 1

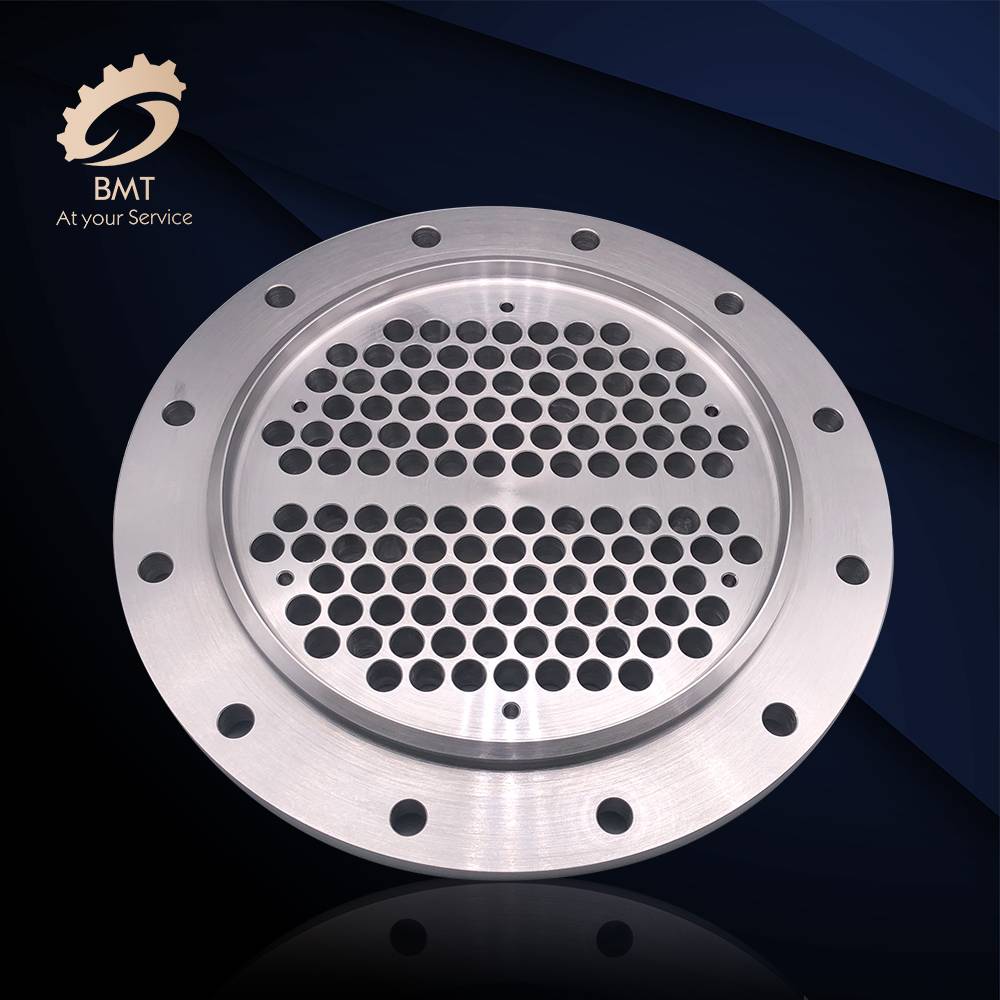

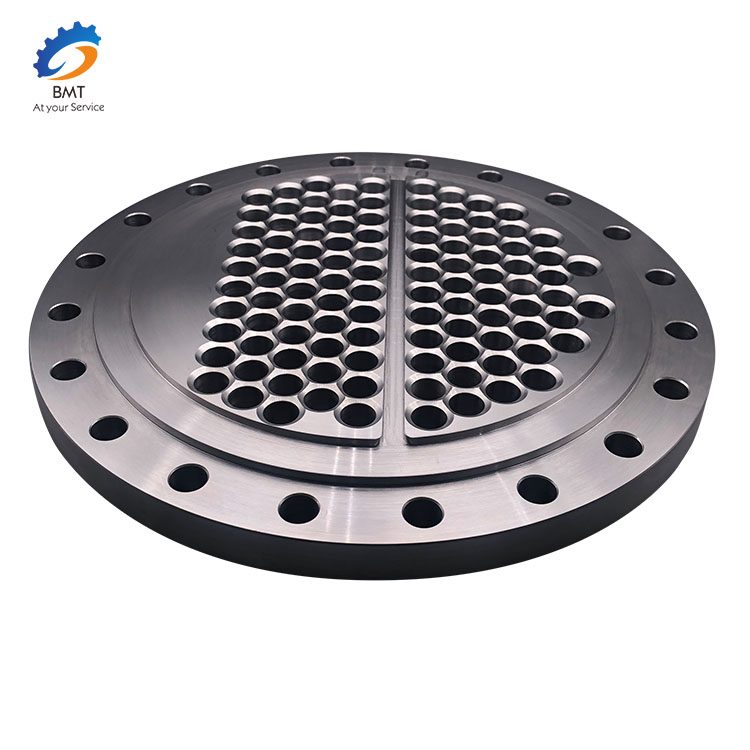

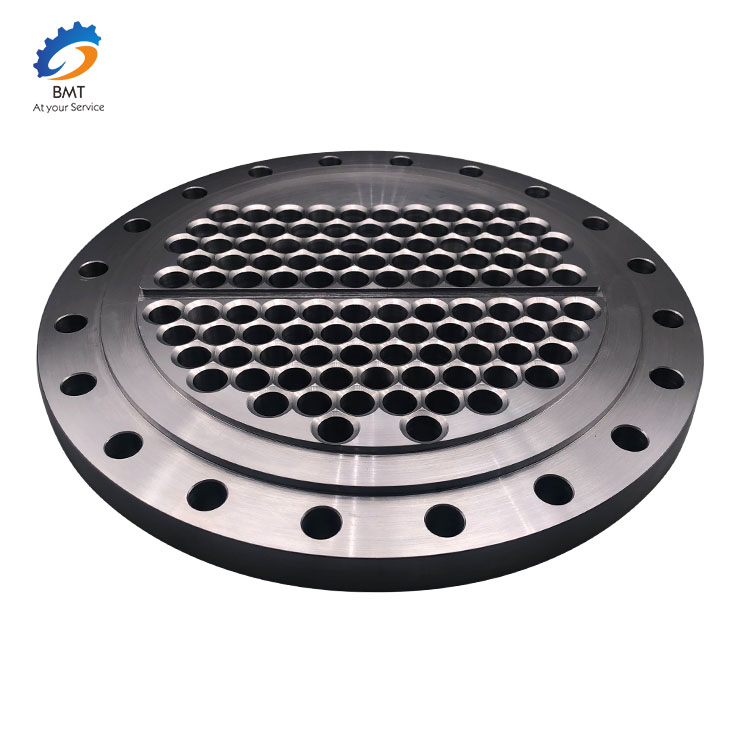

Plate tube 2

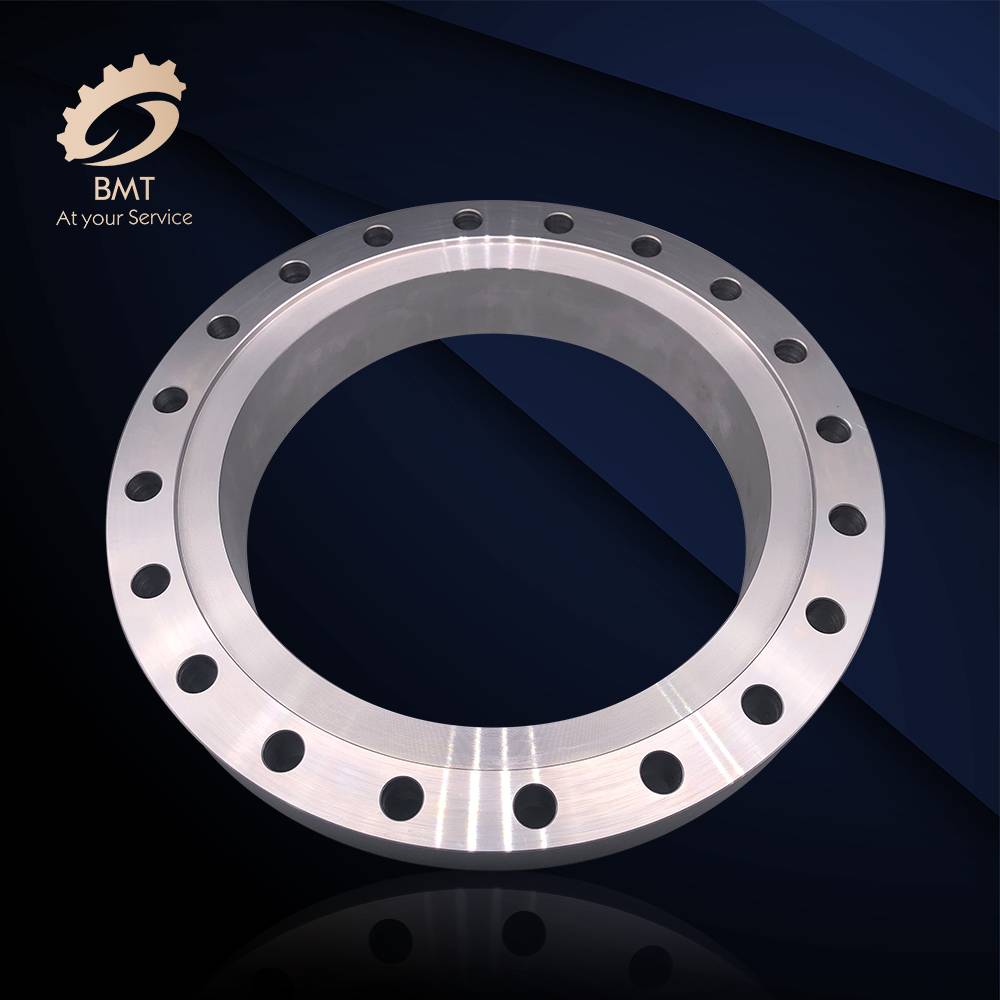

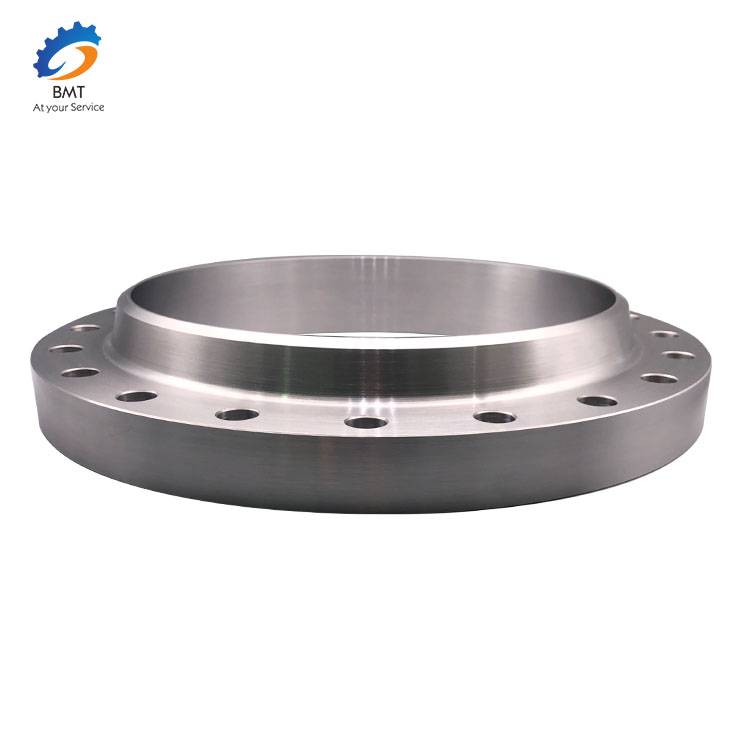

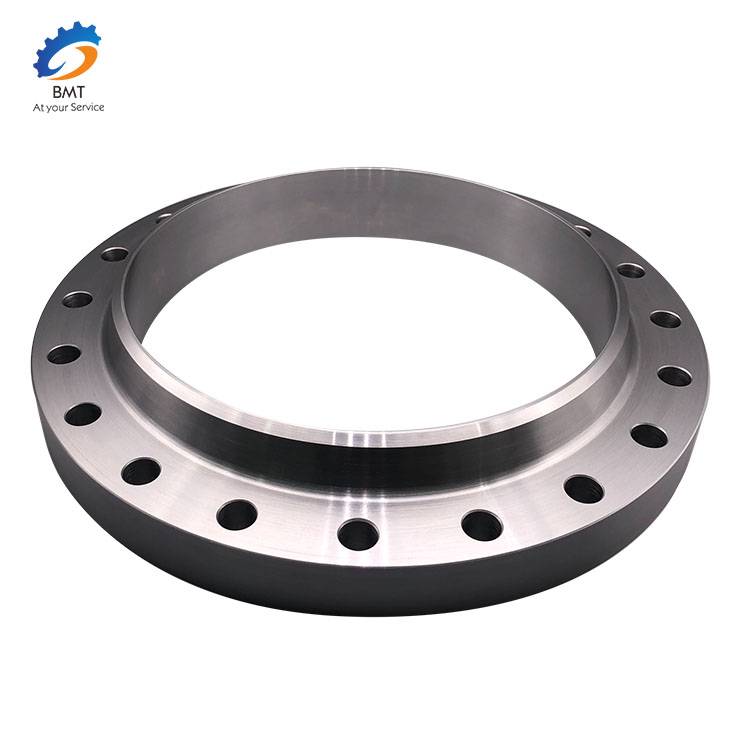

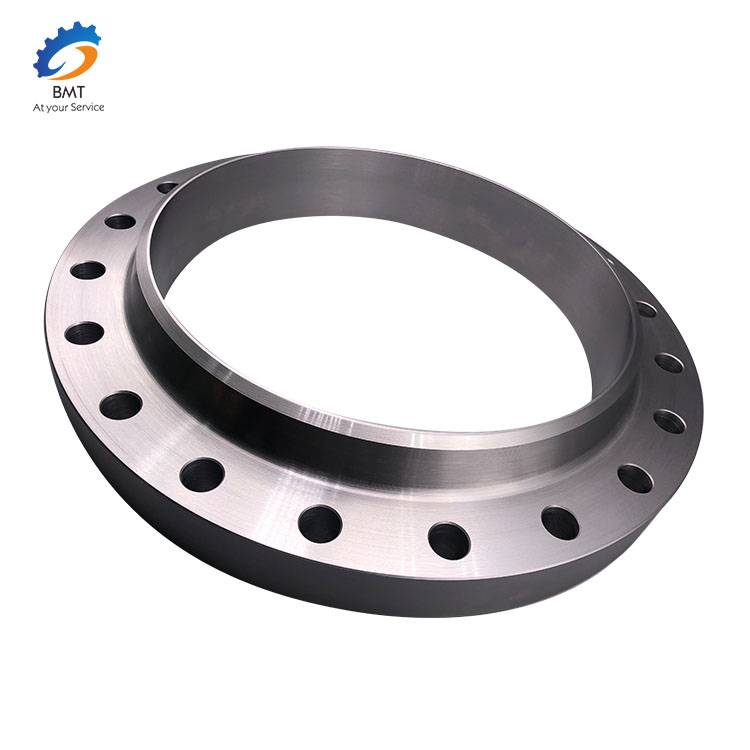

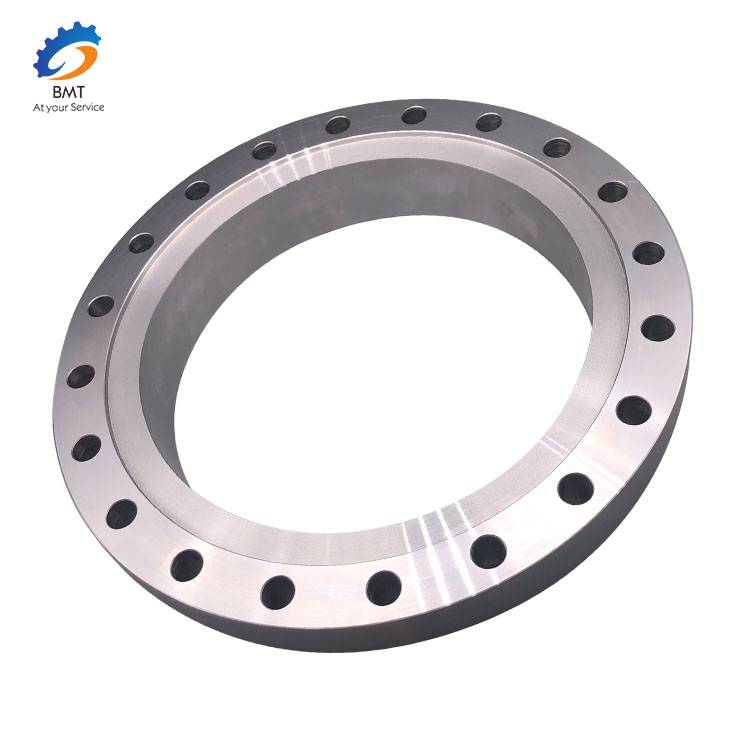

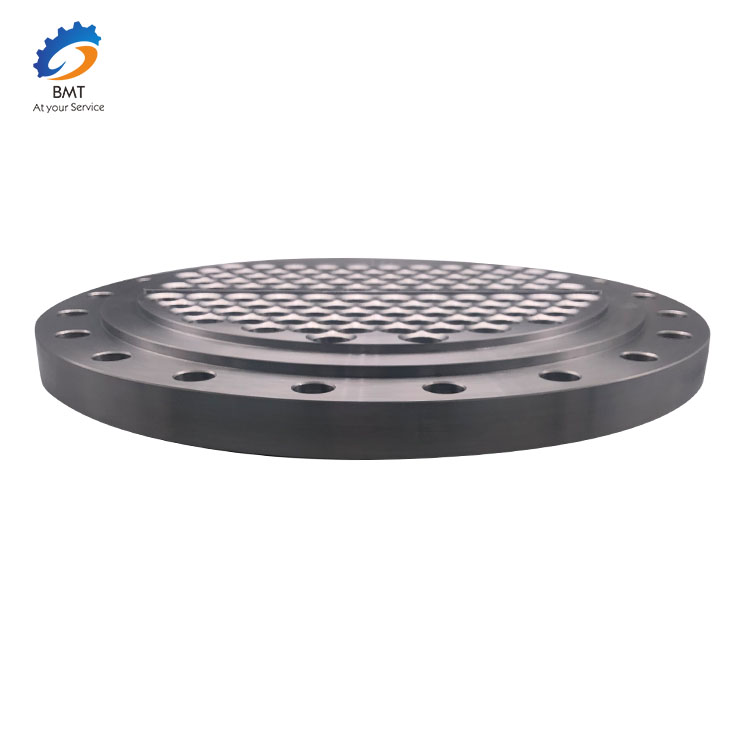

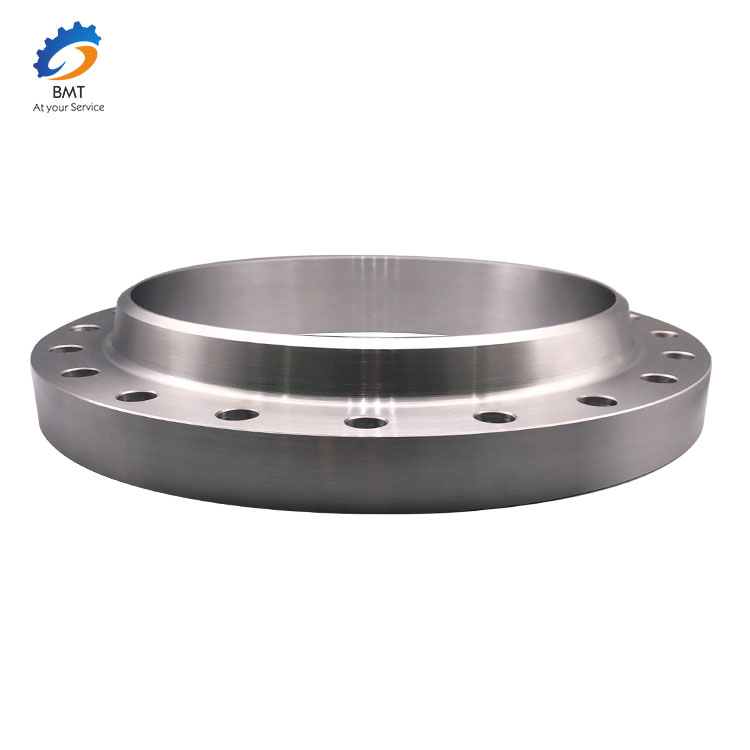

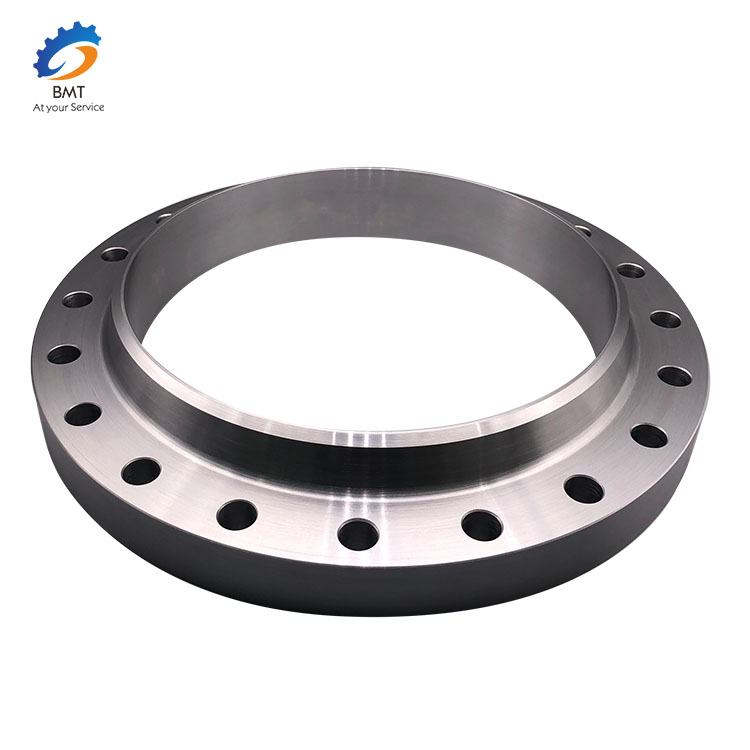

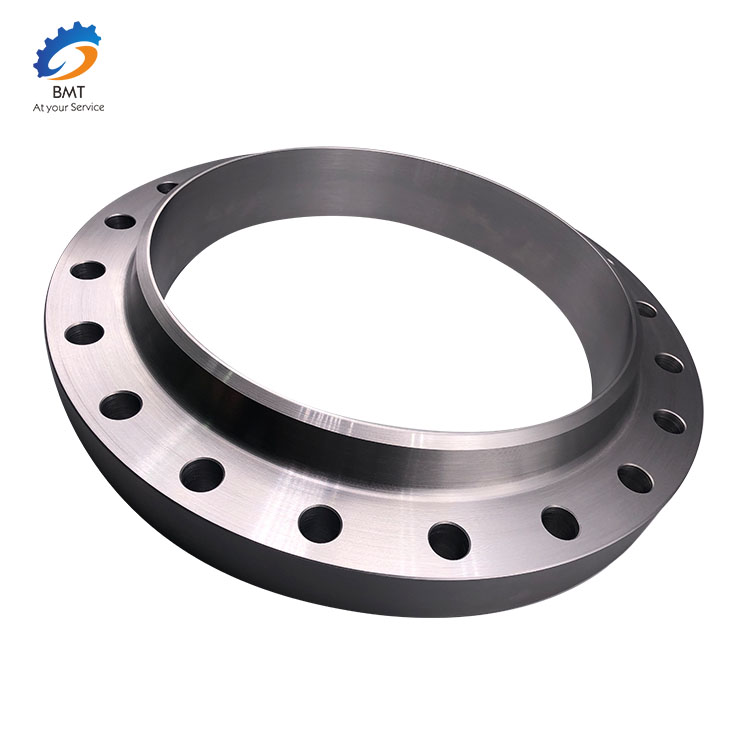

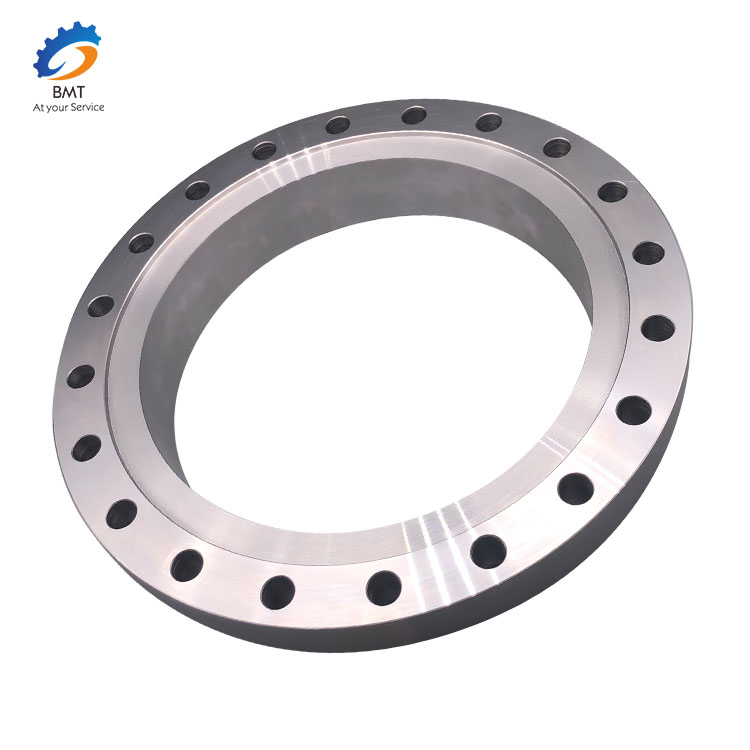

The flange

Plate tube 1

Plate tube 2

The flange

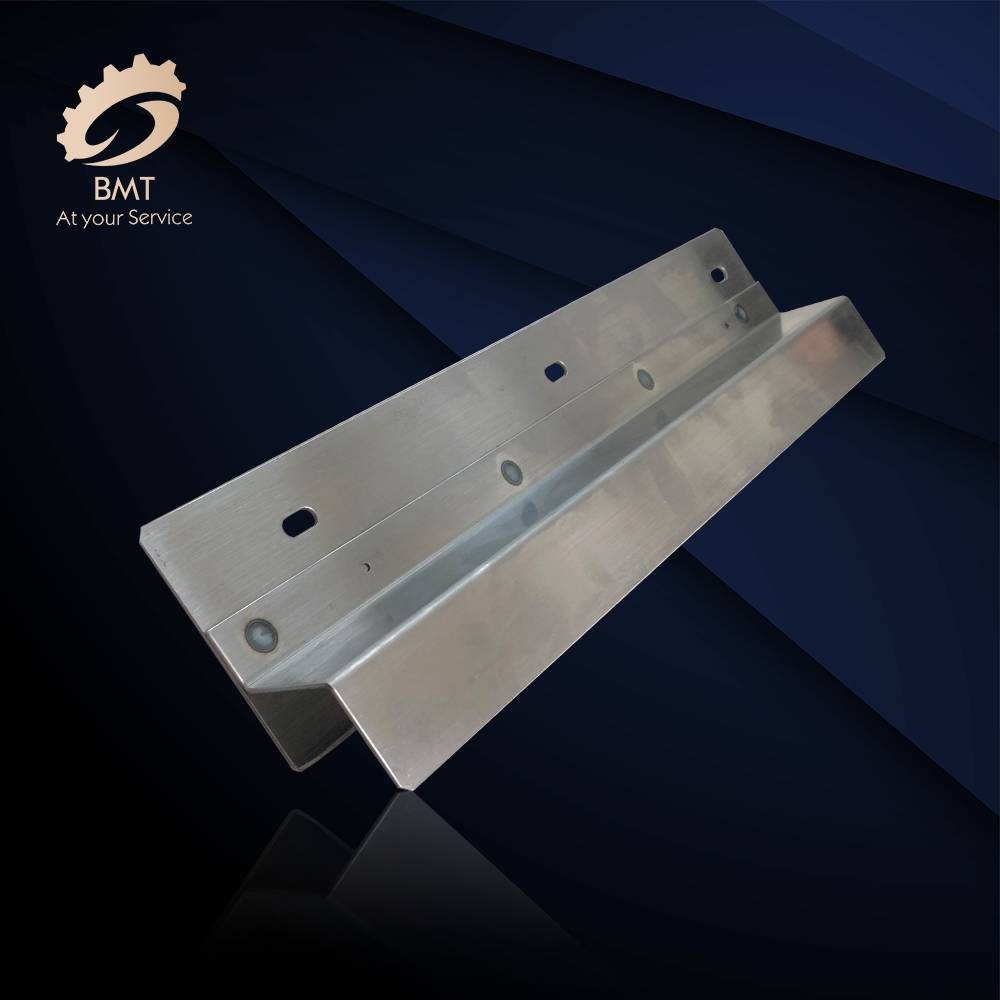

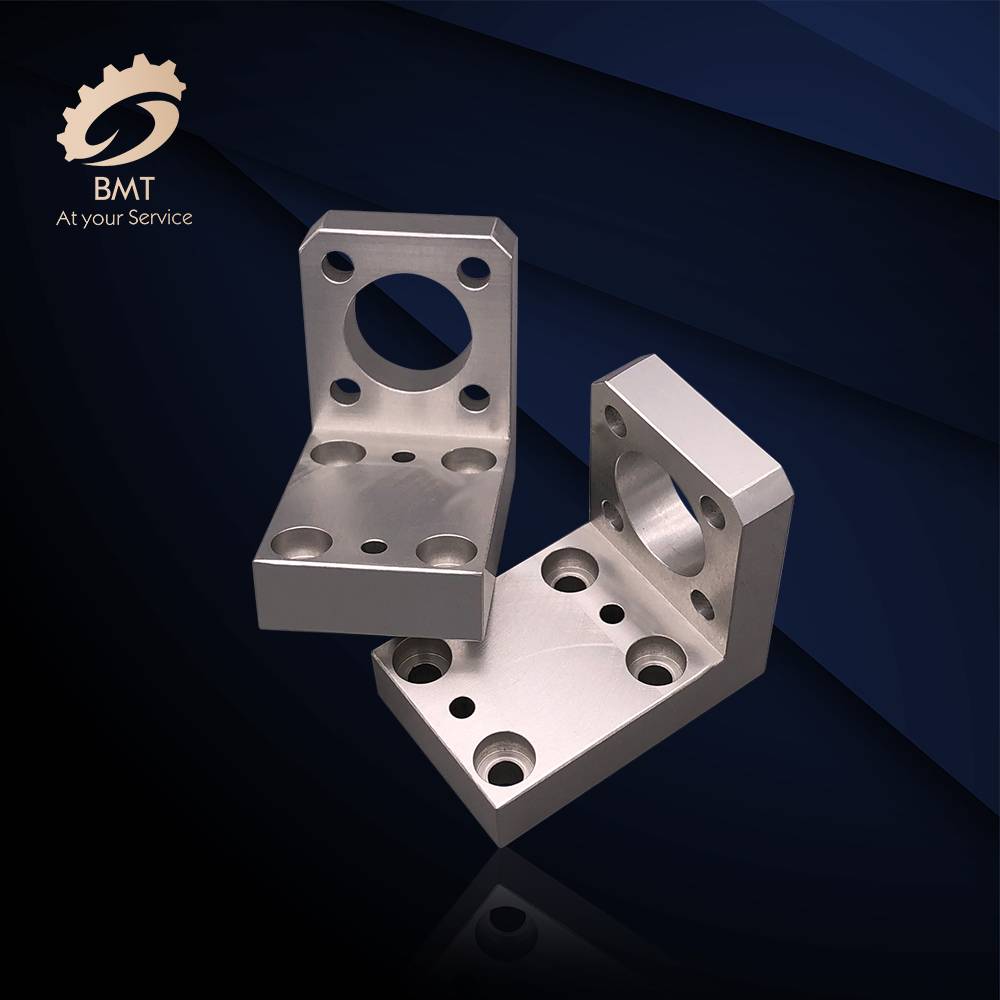

Other Products We Made

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Hot Sale for China OEM Customized High-Pressure Die-Casting Precision Machining Supplier Metal Magnesium-Zinc-Aluminum Alloy Die-Casting Parts, Sincerely hope to build long lasting company relationships with you and we’re going to do our best company in your case.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Hot Sale for China OEM Customized High-Pressure Die-Casting Precision Machining Supplier Metal Magnesium-Zinc-Aluminum Alloy Die-Casting Parts, Sincerely hope to build long lasting company relationships with you and we’re going to do our best company in your case.

Hot Sale for China Die Casting, Aluminum Die Casting, In the new century, we promote our enterprise spirit “United, diligent, high efficiency, innovation”, and stick to our policy”basing on quality, be enterprising, striking for first class brand”. We would take this golden opportunity to create bright future.