“Based on domestic market and expand abroad business” is our progress strategy for 2019 Latest Design China Precision Metallic CNC Machined Parts, We sincerely welcome mates from all over the globe to cooperate with us to the basis of long-term mutual added benefits.

“Based on domestic market and expand abroad business” is our progress strategy for China Customized Machined Parts, Machinery Parts Making, Adhering to the management tenet of “Managing Sincerely, Winning by Quality”, we try our best to offer excellent products and solutions and service to our clients. We look forward to making progress together with domestic and international clients.

Technology Characterizes of Mechanical Precision Machining

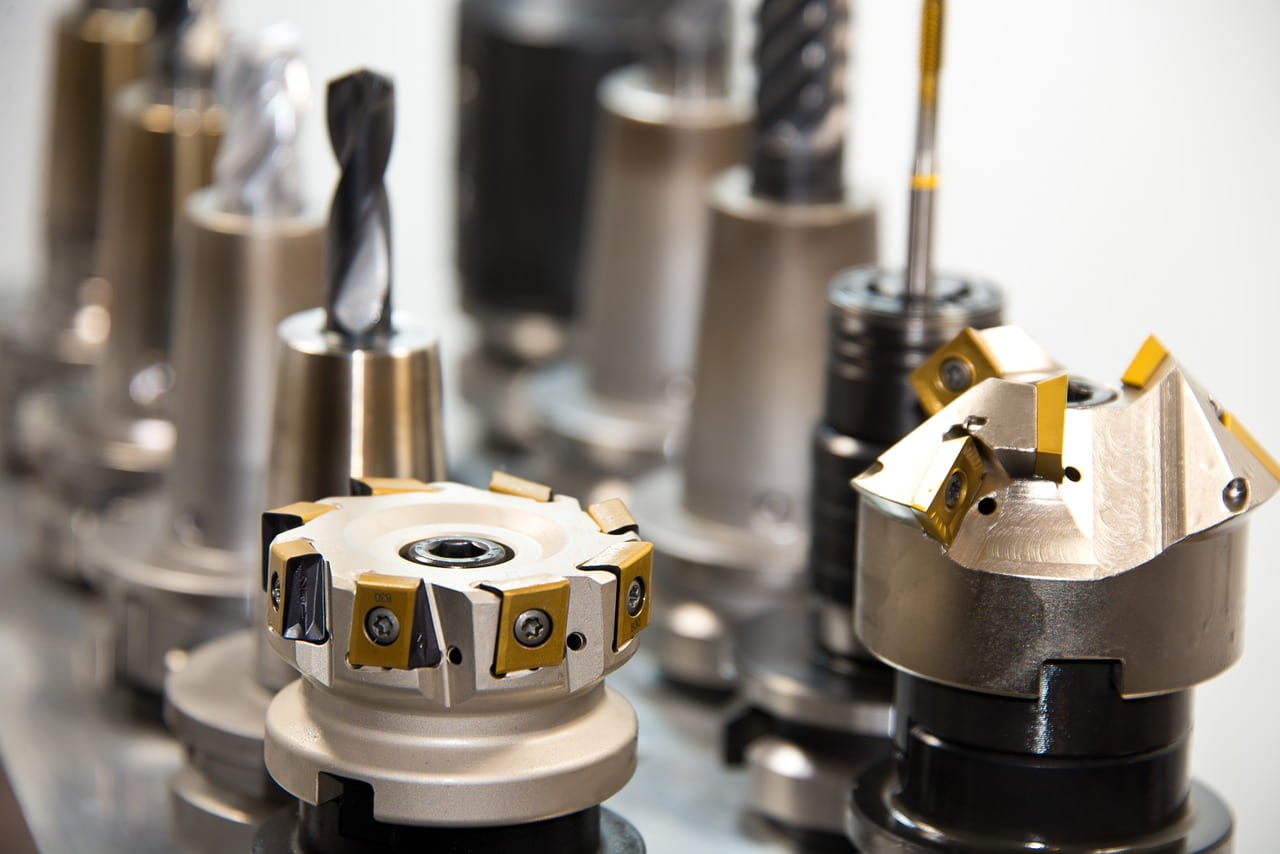

(1) Precision Cutting Technology

Generally, precision cutting technology is directly using the cutting way to get high precision, so it has better requirements of the cutting products. For example, the requirement of high precision surface roughness must be met. But it is worth noting that if you want to use the cutting way to get a high precision and high level of surface roughness, you should be actively excluded from the influence of machine tools, tools, workpiece and outside factors. For example, in order to continuously improve the machining accuracy and accuracy of the machine tool, it is necessary to choose the machine tool with high stiffness, small thermal deformation, and good vibration resistance performance.

(2) Ultra-Precision Grinding Technology

For machining, aiming at reaching 1-2mm surface roughness, and the use of atomic level grinding polishing silicon wafer. The previous grinding, abrasive machining, polishing and other traditional processing methods cannot meet the needs of this work. Therefore, new principles and methods must be analyzed and studied in depth. It is under this background that ultra-precision grinding technology arises at the historic moment and plays an increasingly important role in mechanical precision technology.

(1) The Relevance of Modern Mechanical Manufacturing Technology and Mechanical Precision Machining Technology.

In terms of manufacturing technology, modern mechanical manufacturing technology and precision processing technology are involved in many aspects of the mechanical industry, such as manufacturing engineering, product design and development, product process design, processing and manufacturing, product sales, etc. Once problems happened in these industries, they will directly affect the whole engineering chain. Therefore, we must attach great importance to the correlation between modern machinery manufacturing industry and precision machining technology, so as to truly promote the progress and development of mechanical technology. Therefore, in practice, modern mechanical technology and precision machining technology must be fully combined to promote mechanical progress and achieve rapid development and progress of technology.

(2) Systematic of Modern Mechanical Manufacturing Technology and Mechanical Precision Machining Technology.

Modern machinery manufacturing production is complicated system engineering in the use of modern machinery manufacturing technology and precision processing technology, such as product design, production and sales, which will involve computer information technology, modern sensing technology, production automation technology and many other technologies. In addition, there may be a need to apply new materials, new management methods, etc. Therefore, overall speaking, the manufacturing technology of the machinery industry cannot be separated from the comprehensive application of a variety of modern advanced technology, which requires the modern machinery manufacturing technology and precision processing technology to have a greater system.

(3) The Globalization of Modern Mechanical Manufacturing Technology and Precision Machining Technology.

At present, with the development of economic globalization, many economic fields of our country have gradually realized the integration with the international trend. The economic globalization has developed the important trend of encirclement current social development. At the same time, under the background of economic globalization, the market competition intensifies, machinery manufacturing industry in our country in order to promote the competitiveness of enterprises in the domestic and international market, we must follow the time development, actively introduce international advanced mechanical manufacturing technology and precision machining technology, increase investment in enterprise internal research cultivate high-level technical personnel, research and development accord with the actual situation of enterprises machinery manufacturing technology and precision machining technology, so as to realize the healthy and sustainable development of machinery manufacturing enterprises.

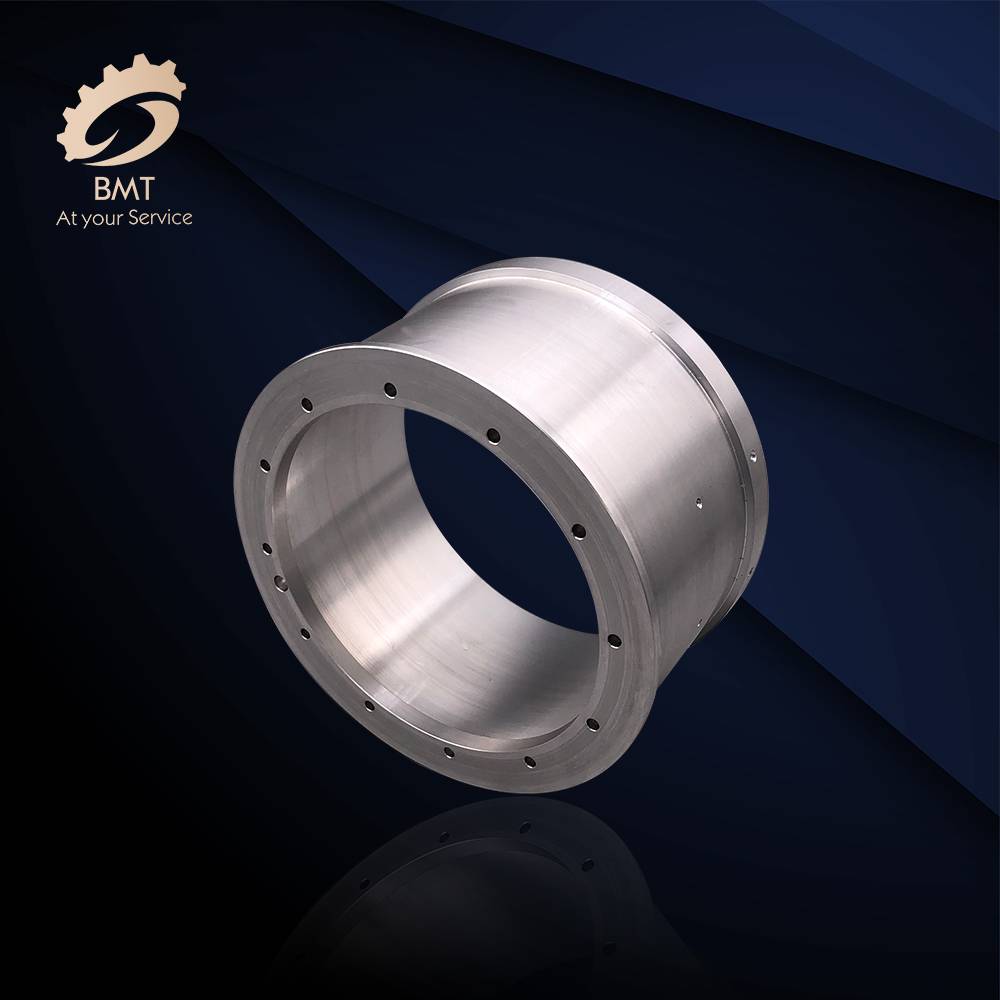

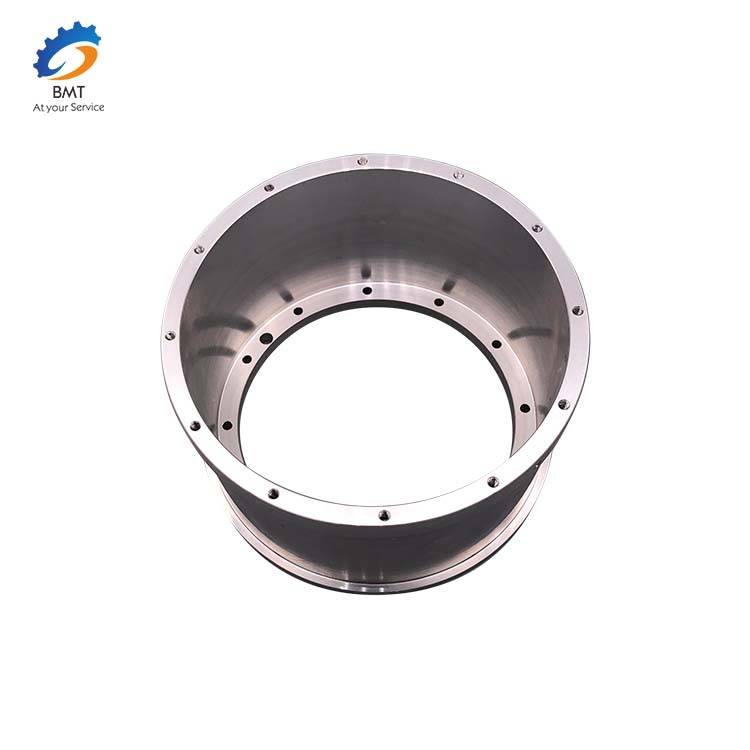

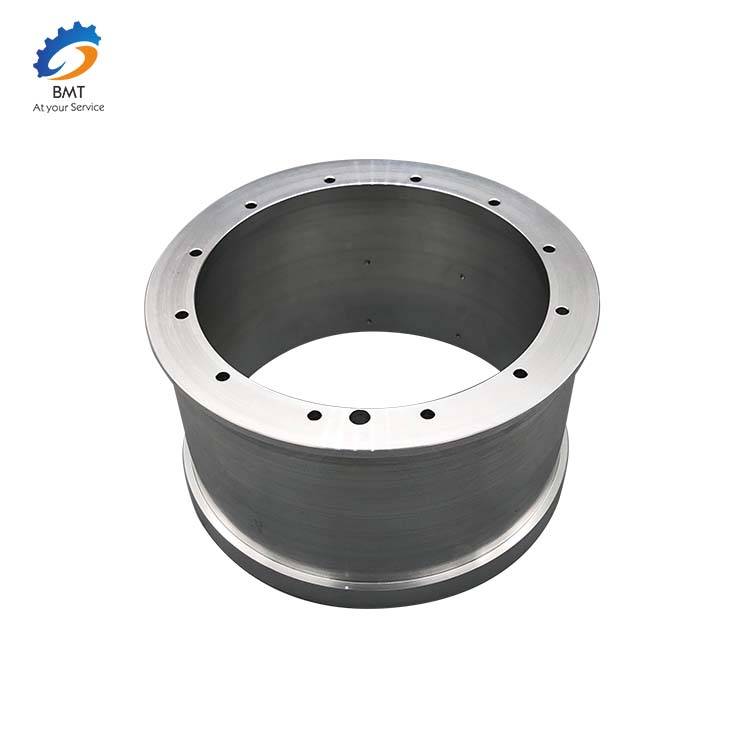

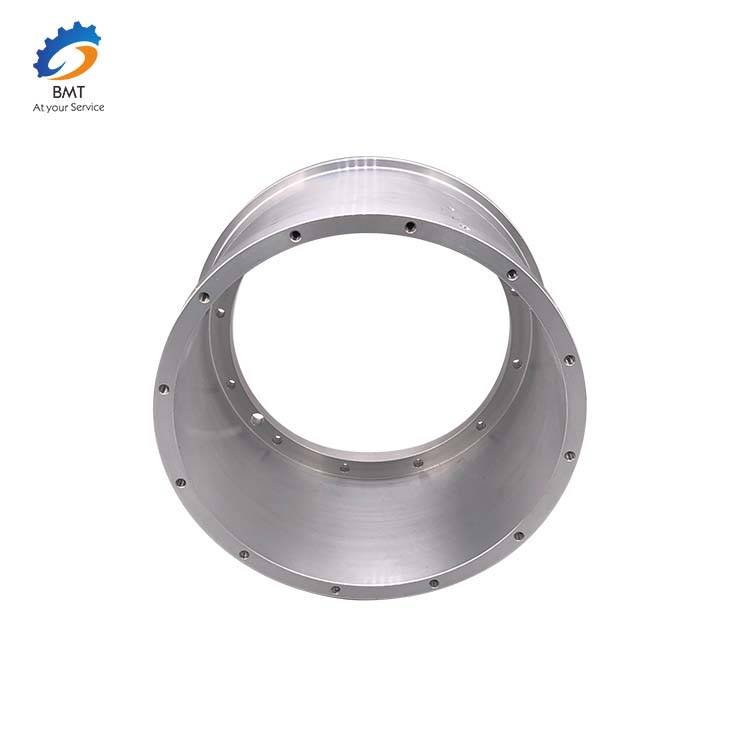

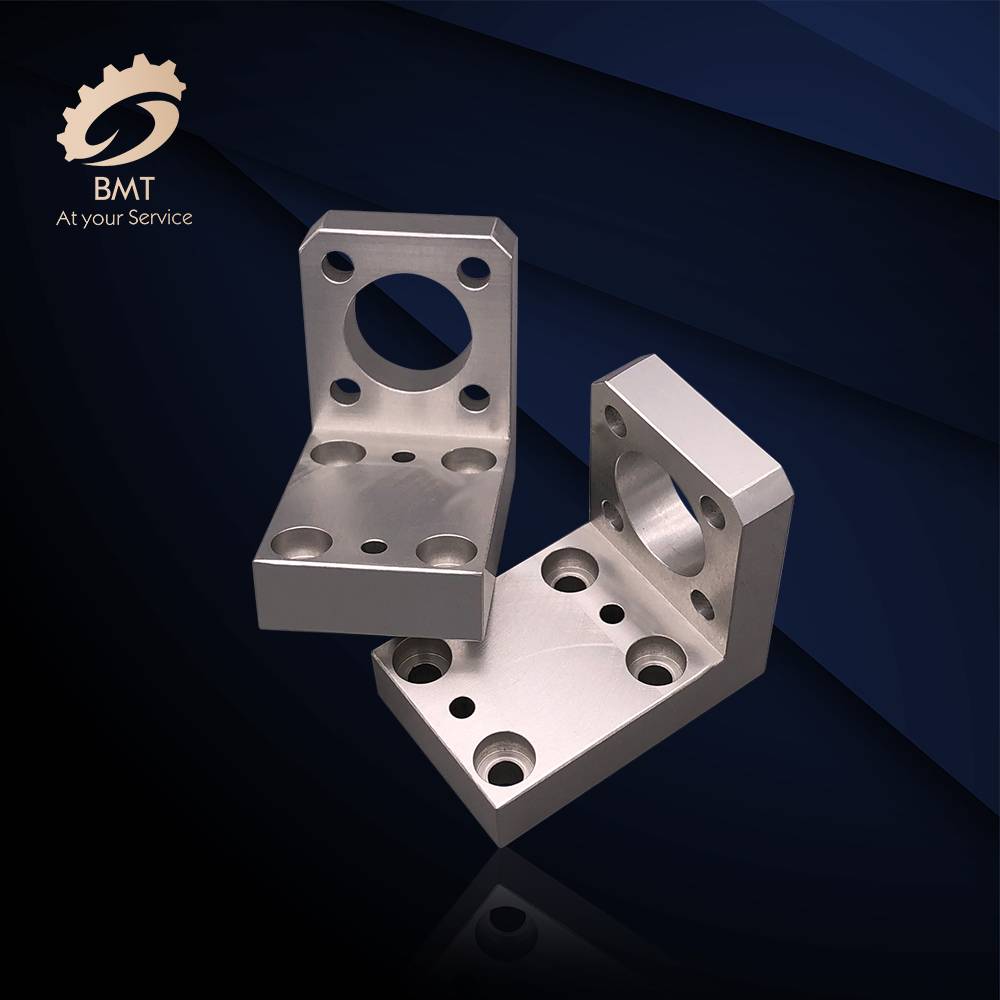

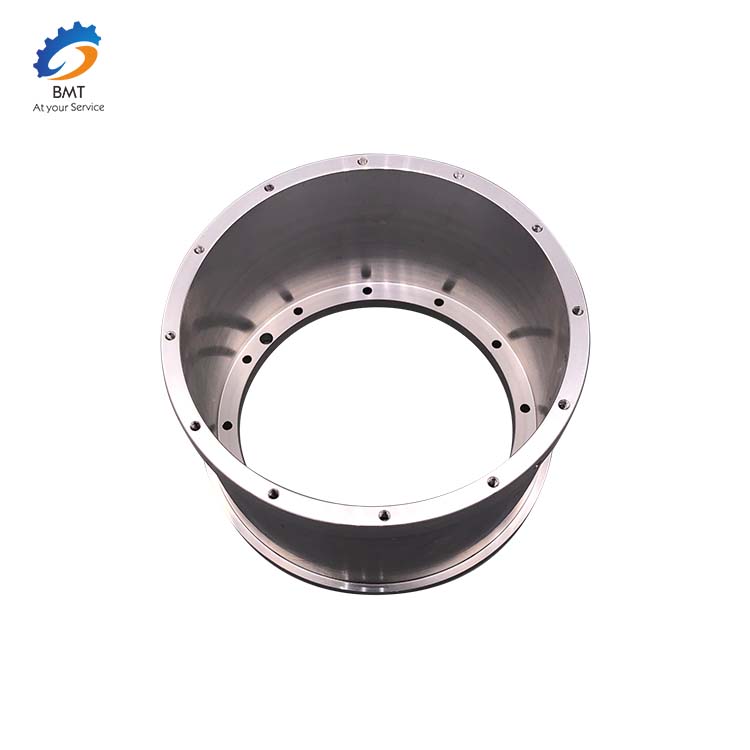

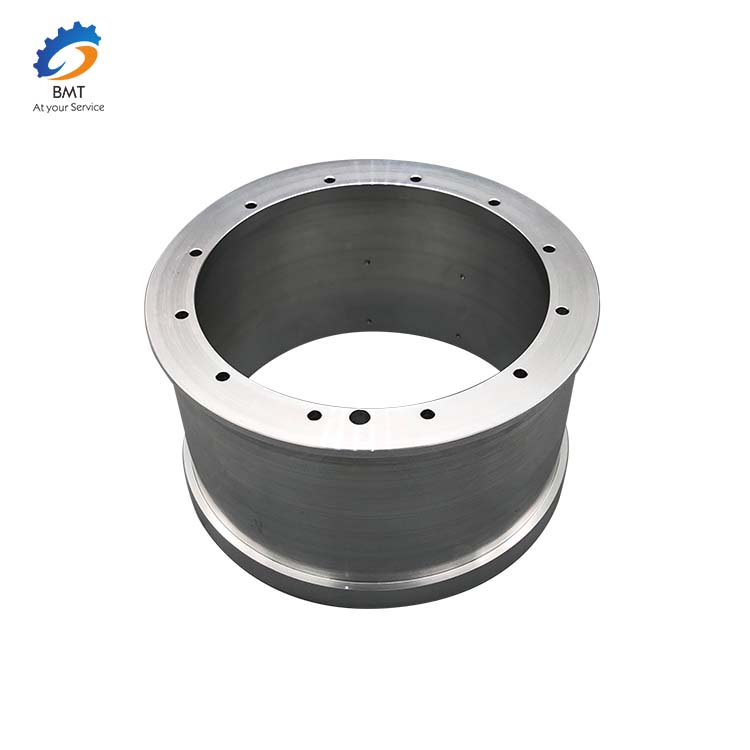

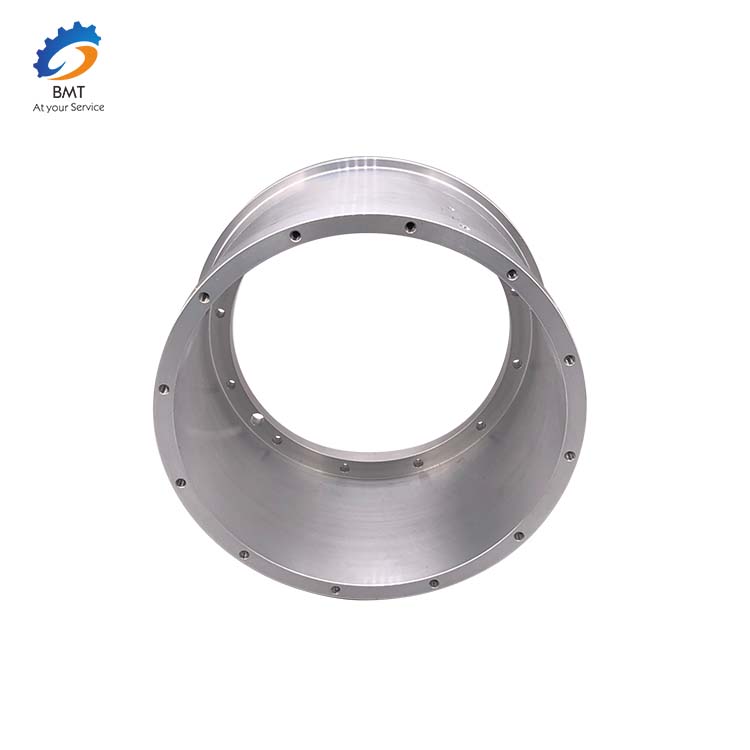

Product Description

Precision Machining Parts

Precision Machining Parts

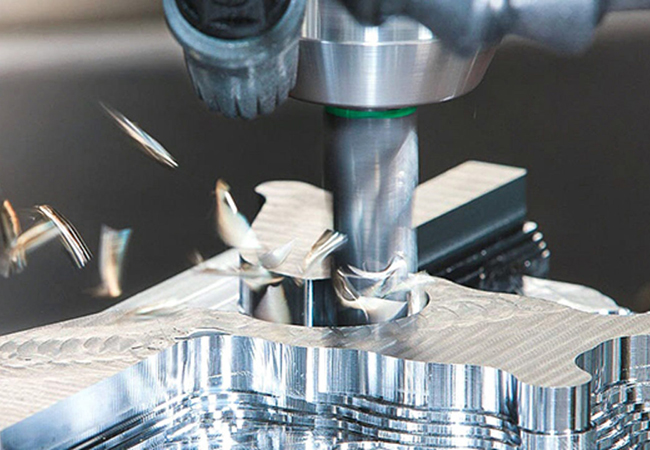

Before CNC manufacturing, manufacturing was done exclusively my manual machinery operated and supervised a person at all times. Not only it led to fewer products getting manufactured but it also caused significant errors in final products. Incorporating computers into manufacturing increased the speed and accuracy of manufacturing equipment by thousand folds. All you have to do is insert the basic commands into the software and it will process the raw material through the machinery with utmost perfection. Today, all custom machining services have CNC as their core element. From milling, lathe, precision cutting, and turning, every manufacturing activity is done through CNC machining to maximize the economy of scale.

In the upcoming years, cloud computing, and virtual reality will play a significant role in CNC manufacturing. All the topmost CNC machine shops are making the most out of widespread internet to keep the manufacturing process running 24/7. CNC machines can be operated remotely without first-hand human interaction, significantly reducing the risk of workplace hazards. Virtual and augmented reality will make manufacturing even more immersive. Machining services providers can customize the tiniest detail in product design to maximize its usability. Other crucial software updates include a touch screen mechanism and virtual simulations under a controlled environment.