We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation for China Brass/Steel/Aluminum/Metal Parts, Custom Milling Machinery Service Precision CNC Machining Parts, Customers’ advantage and satisfaction are normally our biggest target. Be sure to call us. Give us a opportunity, offer you a surprise.

We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation for China Machining Parts, Machinery Part, Welcome to visit our company and factory, there are various solutions displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to deliver you the best service

What are CNC Machining and CNC Machining Service?

CNC Machining is a professional term commonly used in mechanical manufacturing and industrial fields, but what does the word “CNC” stand for exactly and what is a CNC Machining Services? The Acronym CNC stands for “Computer Numerical Control”, which means the machines are controlled by computer programs with serial numerical characters.

The definition of CNC Machining is that it’s a subtractive manufacturing process which generally controlled by computer and adopts different kinds of machine tools to remove material from the workblank and manufactures a custom-designed part. This process is suitable for a wide range of materials, including metals, plastics, wood as well as glass. This process also applied in a variety of industries, such as Automotive, Aerospace, and Agricultural.

Speaking in terms of the machine itself, the definition of CNC machine is that it represents the actual programmable machine that is capable of autonomously performing the operations of CNC machining.

Manufacturing processes include subtractive manufacturing processes, additive manufacturing processes and formative manufacturing processes. The subtractive manufacturing processes, so called CNC machining, are different from additive manufacturing processes, like 3D printing, or formative manufacturing processes, like injection molding. While subtractive processes remove layers of material from the workblank to get custom designed parts, additive processes assemble layers of material to produce the desired form and formative processes deform and displace stock material into the desired shape.

CNC machining provides high precision and high accuracy products, and enables cost-effectiveness when fulfilling one-off, medium-volume and mass production. However, although CNC machining has certain advantages of complicated parts over other manufacturing processes, it also has its limitations of complex designs.

In conclusion, each type of manufacturing process has its advantages and disadvantages, so we focus on high precision CNC machining services, Sheet Metal and Stamping services over decade of years. We are professional in CNC Milling, Turning, Grinding, Cutting, drilling, chamfering, etc. If you are trying to find reliable CNC Machining suppliers with good pre-sales services and after-sales services, BMT exists to solve all of your quick turn-around manufacturing problems. We provide you cost-effectiveness products with high quality service you need.

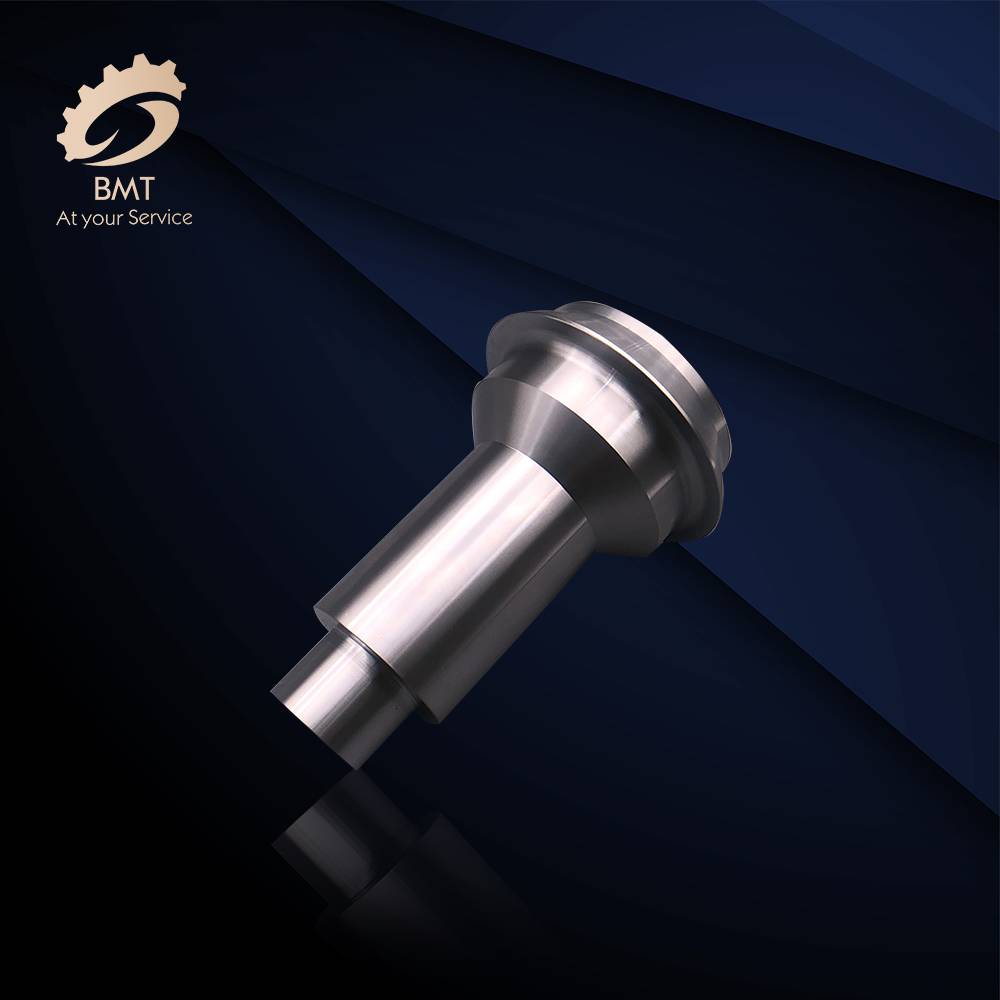

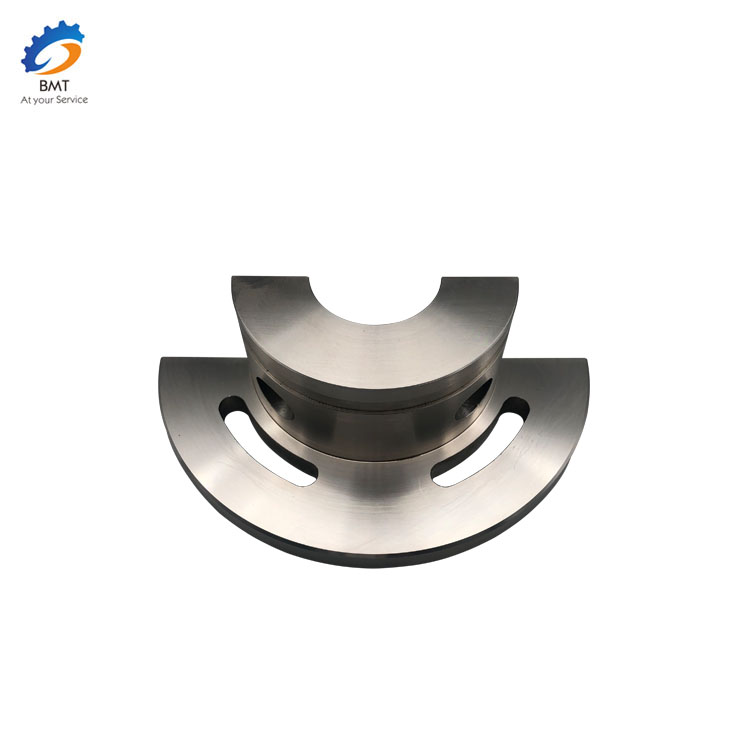

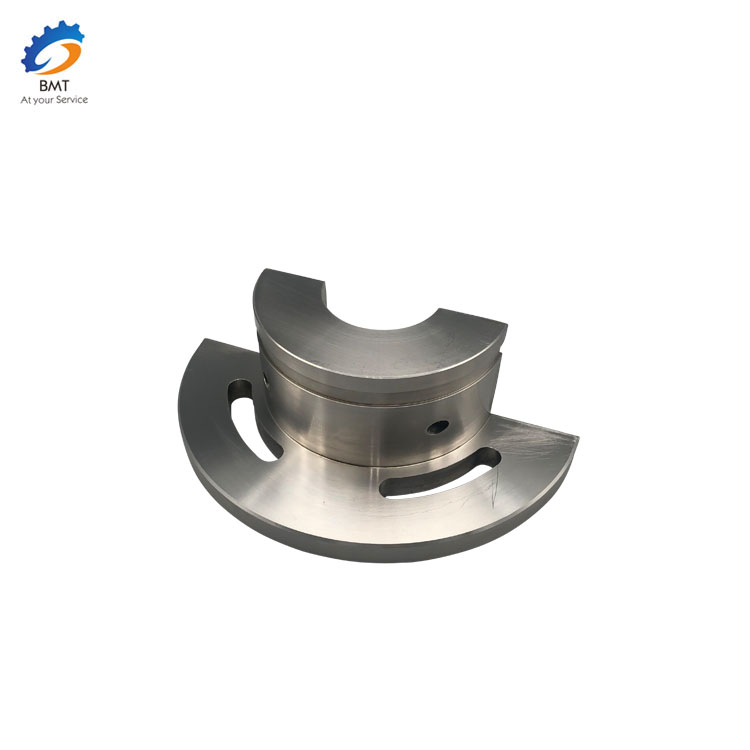

Product Description

CNC Machining Companies

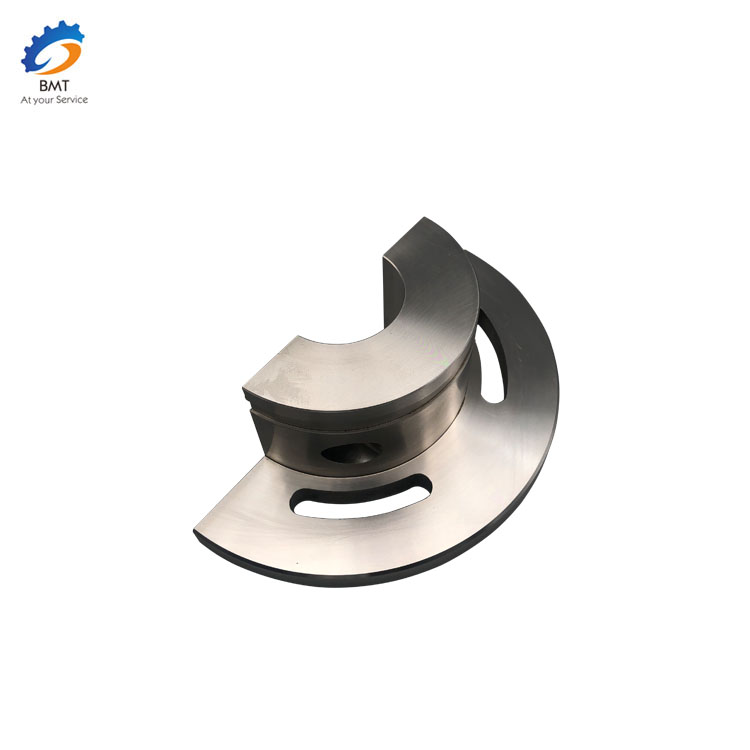

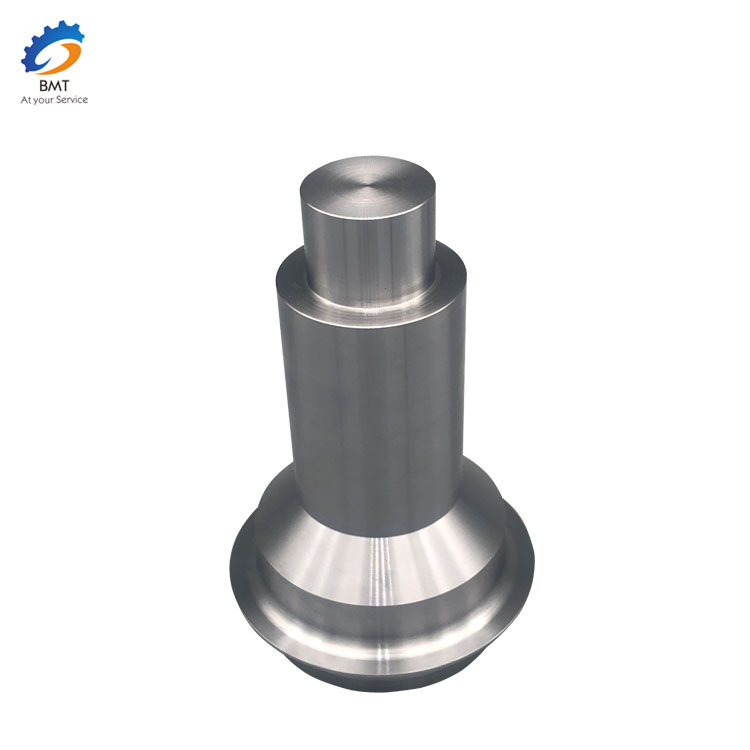

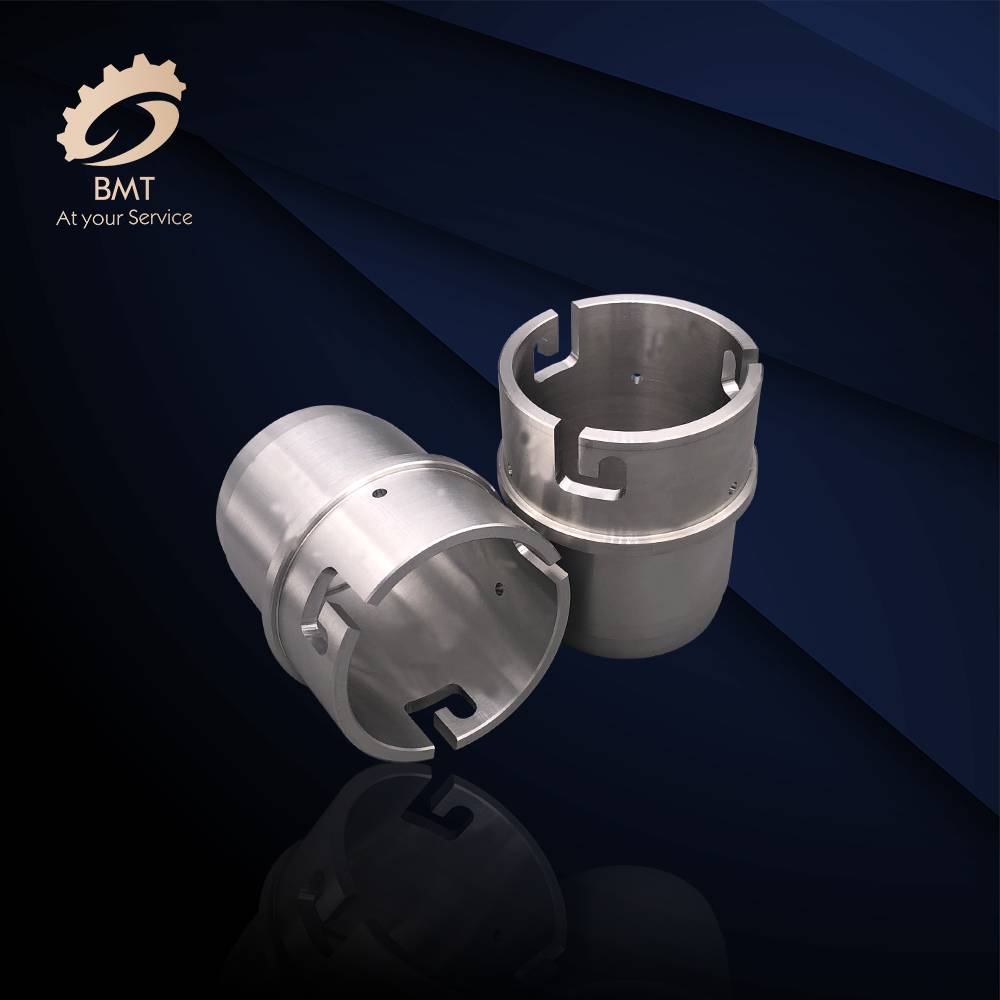

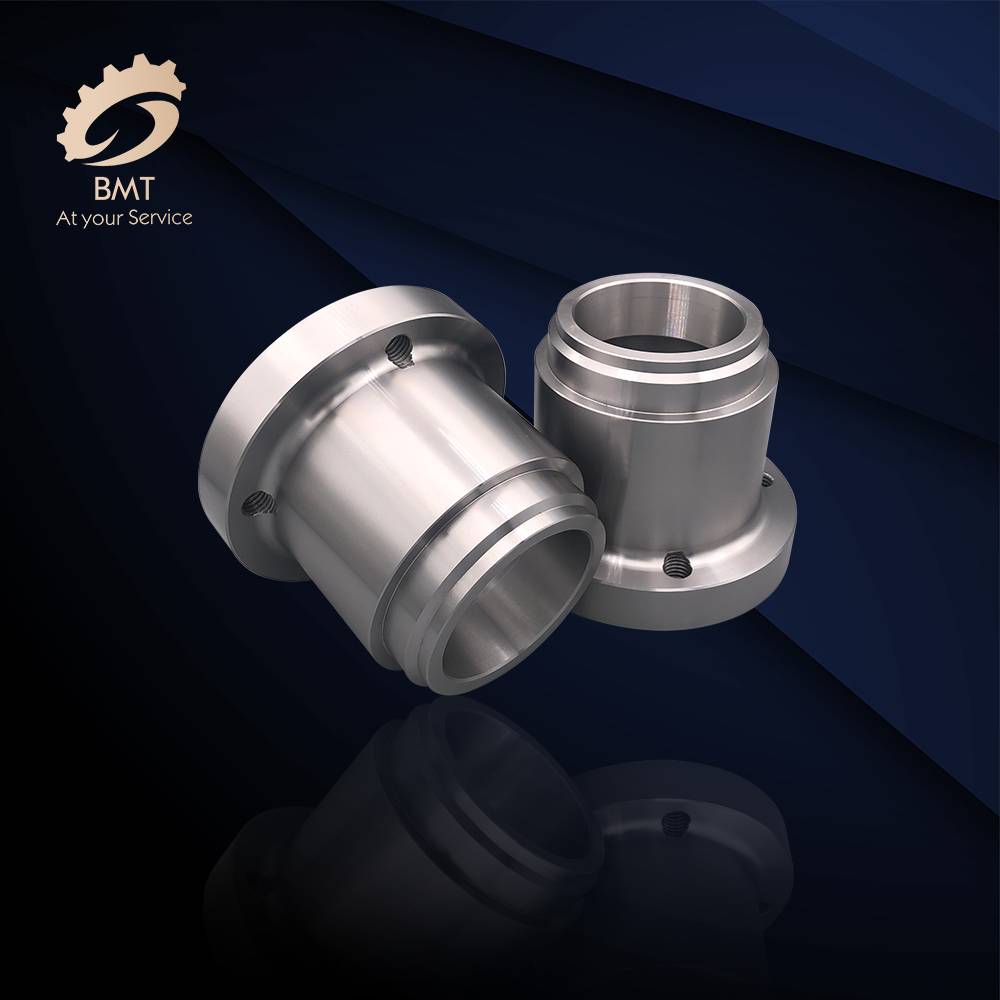

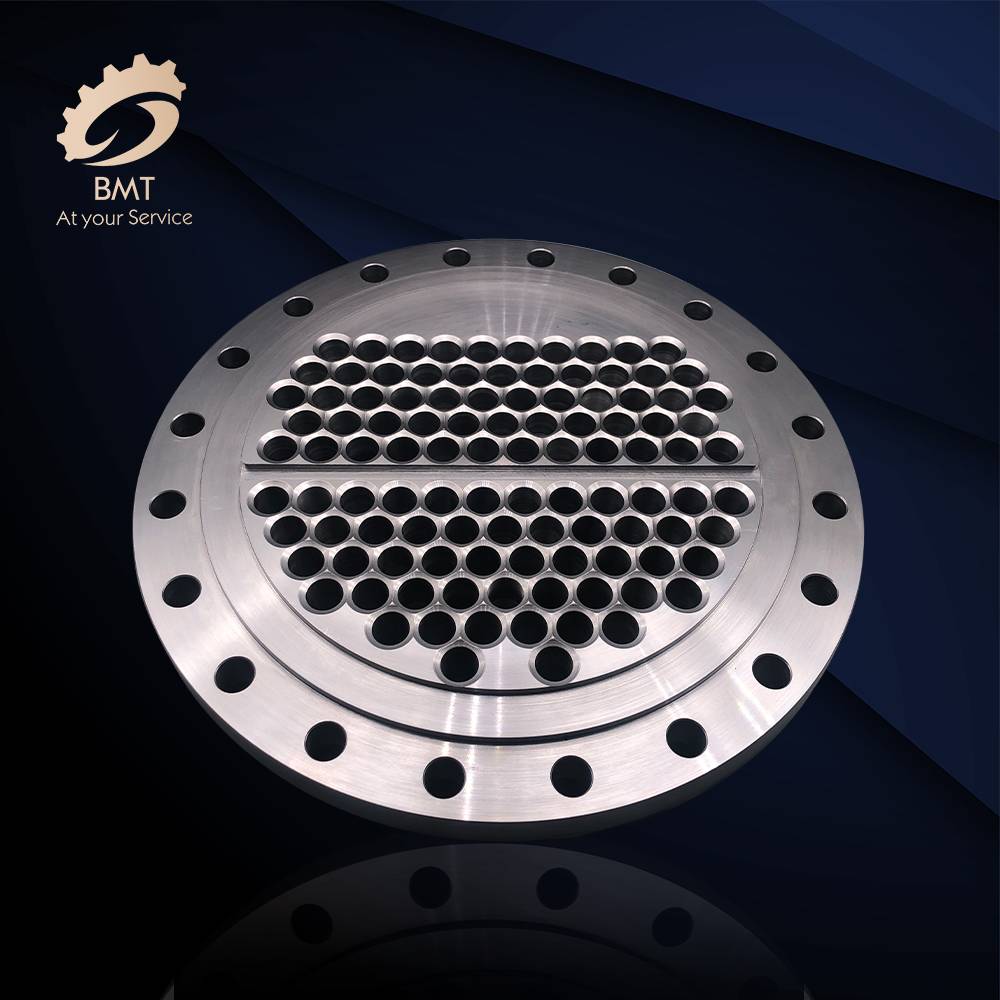

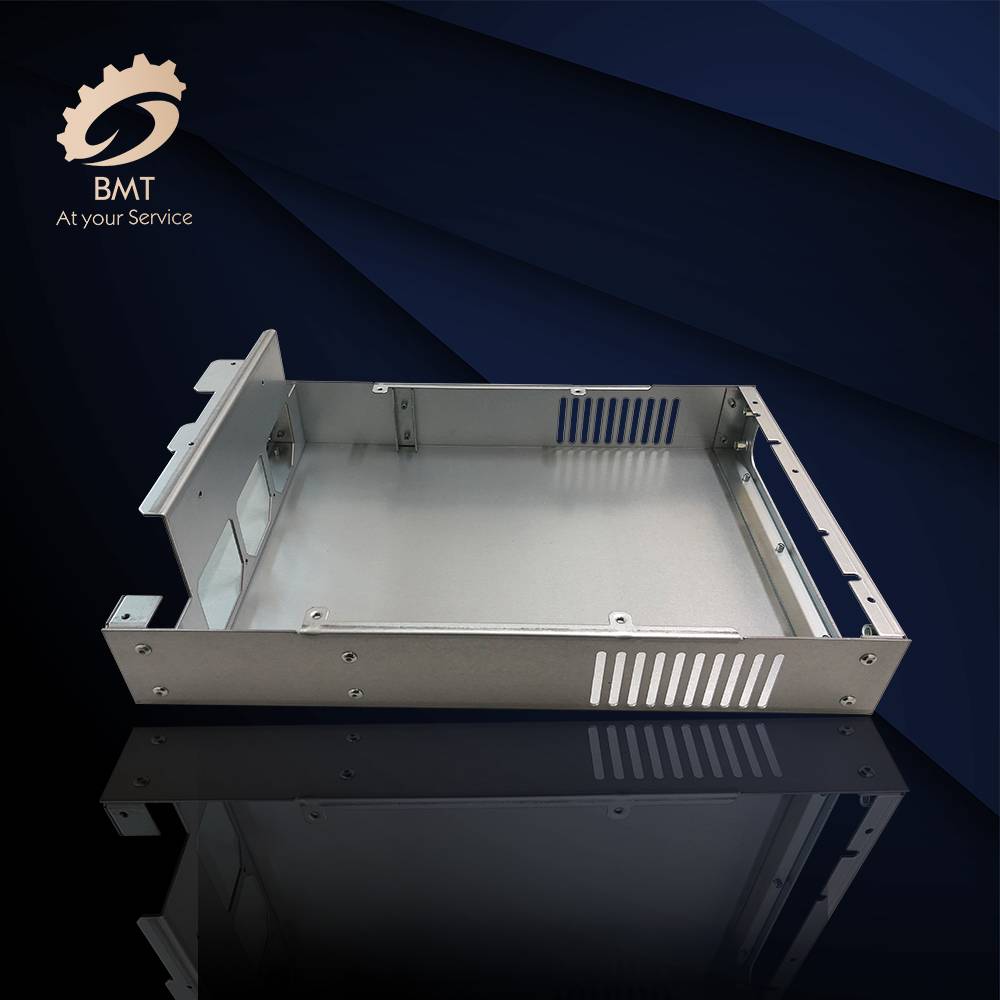

Stainless Steel Machined Part

CNC Machining Companies

Stainless Steel Machined Part

We provide fantastic power in high-quality and development,merchandising,profits and marketing and advertising and operation for Wholesale ODM China Brass/Steel/Aluminum/Metal Parts, Custom Milling Machinery Service Precision CNC Machining Parts, Customers’ advantage and satisfaction are normally our biggest target. Be sure to call us. Give us a opportunity, offer you a surprise.

Wholesale ODM China Machining Parts, Machinery Part, Welcome to visit our company and factory, there are various solutions displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to deliver you the best service

Electric discharge machining (EDM): Also known as spark machining, this process uses electric arcing discharges to create micro-craters that rapidly result in complete cuts. EDM is used in applications requiring complex geometrical shapes in hard materials and at close tolerances. EDM requires the base material to be electrically conductive, which limits its use to ferrous alloys.

Send your message to us:

-

Original Factory China CNC Machining Parts Anod...

-

15 Years Exporter China OEM Customized Machine ...

-

Top Suppliers China Custom Bending, Welding, Pu...

-

Wholesale Dealers of China Machining Precision ...

-

Factory Selling China Supplier High End OEM Cus...

-

High Quality China Cheap Design Sheet Metal Las...