Short Lead Time for Cnc Machining Aerospace - Professional OEM CNC Machined Parts – Basile Detail:

Non-standard Custom CNC Machining

Thus it can be seen that CNC machine tool processing technology and general machine tool processing technology are almost same in principle, but the whole process of CNC machine tool processing is active and positive, however, it also has its own characteristics.

Numerical control machining production processes and process flow

1. The Production Process:

The process of converse the raw material into products is called the production process. Production process mainly includes the transportation and storage of raw materials, production preparation, preparation of work blank, mechanical processing, surface treatment, assembly, testing, debugging, anti-oxidation processing and packing of the products, etc.

The production process can also be divided into the production process of the whole machine or the production process of a single part, in terms of the production process of the whole factory coordination or the production process of a single workshop.

2. The Technological Process:

In the specific process of production, change the shape and size of blank materials directly, change to the product we need, and make the finished product or semi-finished products known as technological process. Technological process is a very important and essential part of the whole production process. The main part of mechanical processing factory production process is machining technology process.

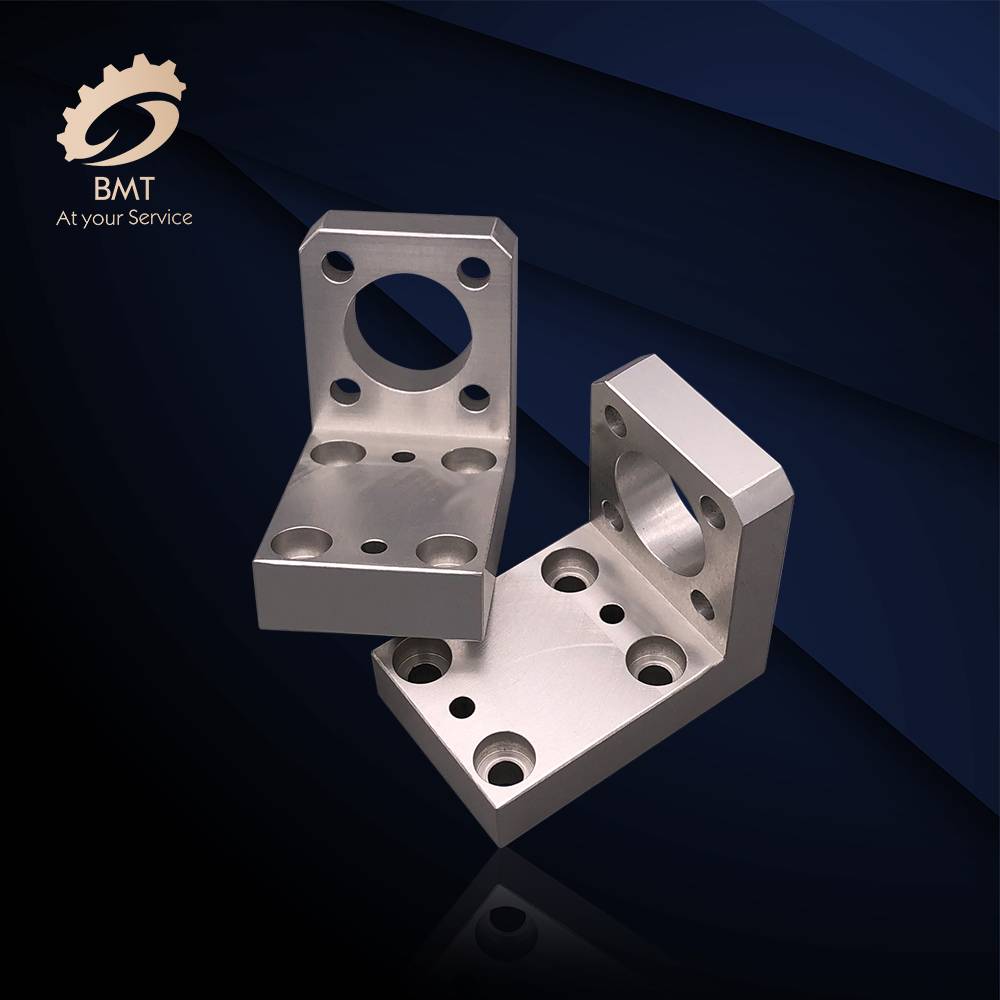

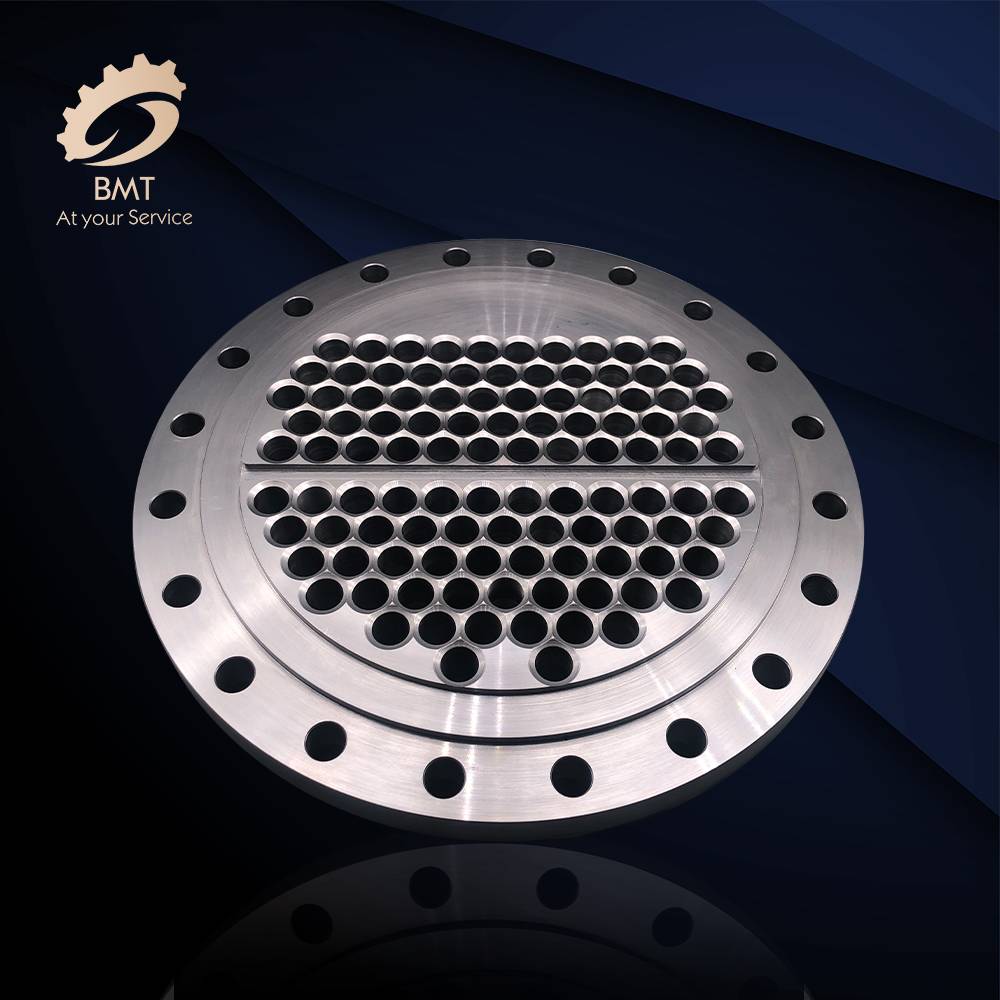

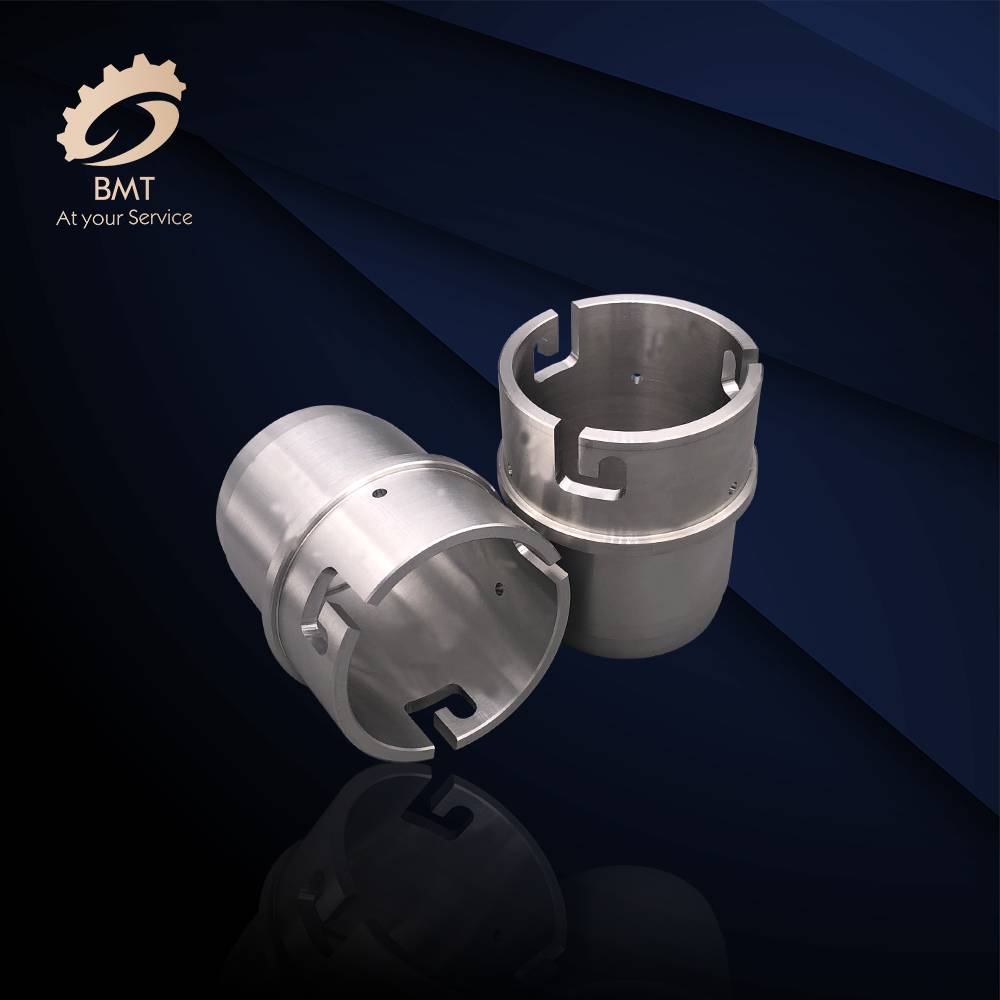

Precision Machining Parts

Precision Machining Parts

What are the Components of mMachining Process Flow?

1. Preparation of Machining Procedure:

Machining process is referring to an operation or a set of operations personnel, work in a fixed place or at a fixed processing machinery, for one or more parts for completion by the part machining process, machining process is the basis of the mechanical processing line component, is also the foundation of arranging production plan unit;

2. The Installation of the Workpiece:

Clamping the part on the machine in one time is known as the installation process. Sometimes, in the same process, the workpiece may need to be installed several times to achieve the ultimate purpose. It should be noted here that the number of installation should be minimized in the process of processing, so as to reduce the error of installation and save more auxiliary time.

3. Process Step:

In the parts’ processing surface, under the unchanged condition of tools, speed and feed, the continuous completion process of that part is called process step. Process step is the basic unit of the machining process;

4. Processing Station:

In order to complete a certain process, after one time clamping, the workpiece and the fixture movable by each position, for example, with the indexing head to milling a hexagonal, each turn is so called a processing station.

5. Feed:

In the same process step, if the processing is relatively large, you need to use the same tool, at the same speed and feed, on the same processing surface for many times cutting, each cutting is so called a feed.

BMT is a professional CNC machinery manufacturers, factory owns precision processing machinery, providing CNC, mechanical machining and other services.

BMT has rich experience in the field of automotive, aerospace, mechanical, food, energy, oil, agricultural, etc., we accept custom parts processing and welcome you for any negotiation.

Product detail pictures:

Related Product Guide:

It really is our obligation to satisfy your requirements and efficiently serve you. Your fulfillment is our greatest reward. We're hunting forward to your check out for joint development for Short Lead Time for Cnc Machining Aerospace - Professional OEM CNC Machined Parts – Basile, The product will supply to all over the world, such as: Tajikistan, Somalia, Estonia, If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!