Quality Inspection for Machined Plastic Parts - Prototype CNC Machining – Basile Detail:

Our Precision CNC Machining Services

Precision machining is often used for parts that require a close tolerance. A professional engineer can manufacture complex parts with precise specifications, using a CNC controlled machine or a specialized lathe. Most machining today is completed with CNC machines and AutoCAD software, and may also use CAM programs. Most designs rely on CAD/CAM programs.

It is also employs on a wide variety of metals including stainless/carbon steel, aluminum, and brass as well as other materials like plastics. Depending on the raw material, various machines can be used. An engineer may need to use lathes, drill presses, milling machines, and high-speed robotics to remove material from the workpiece.

There are some advantages of CNC precision machining. The major advantages include the production of complex precision machined parts with high accuracy while maintaining lower production and setup costs. CNC machining assists in improving the overall degree of accuracy because it is a reliable and fully developed technology that greatly eliminates the possibility of human error. Moreover, by freeing time from operators within the production process, the attention can be focused on quality assurances and offering project oversight, which helps ensure the detailed requirements of production processes are met. Regarding the reduction of costs, CNC machining not only cuts costs by reducing the necessity of skilled operators, but also reduces the overall amount of material waste.

Another advantage is the improvement of workflows from CNC prototyping to full-scale production. At the prototyping level, CNC machines allow developers to quickly build functional designs that can be used for testing. The best result is that the turnaround times are dramatically reduced to save costs. The selection of material to a CNC manufacturing project relies on the particular manufacturing application and its specifications. Most materials can be machined provided that they can withstand the machining process, having sufficient hardness, tensile strength, shear strength, chemical and temperature resistance. The workpiece material and its physical properties are employed to determine the optimal cutting speed, cutting feed rate, and cutting depth.

Product Description

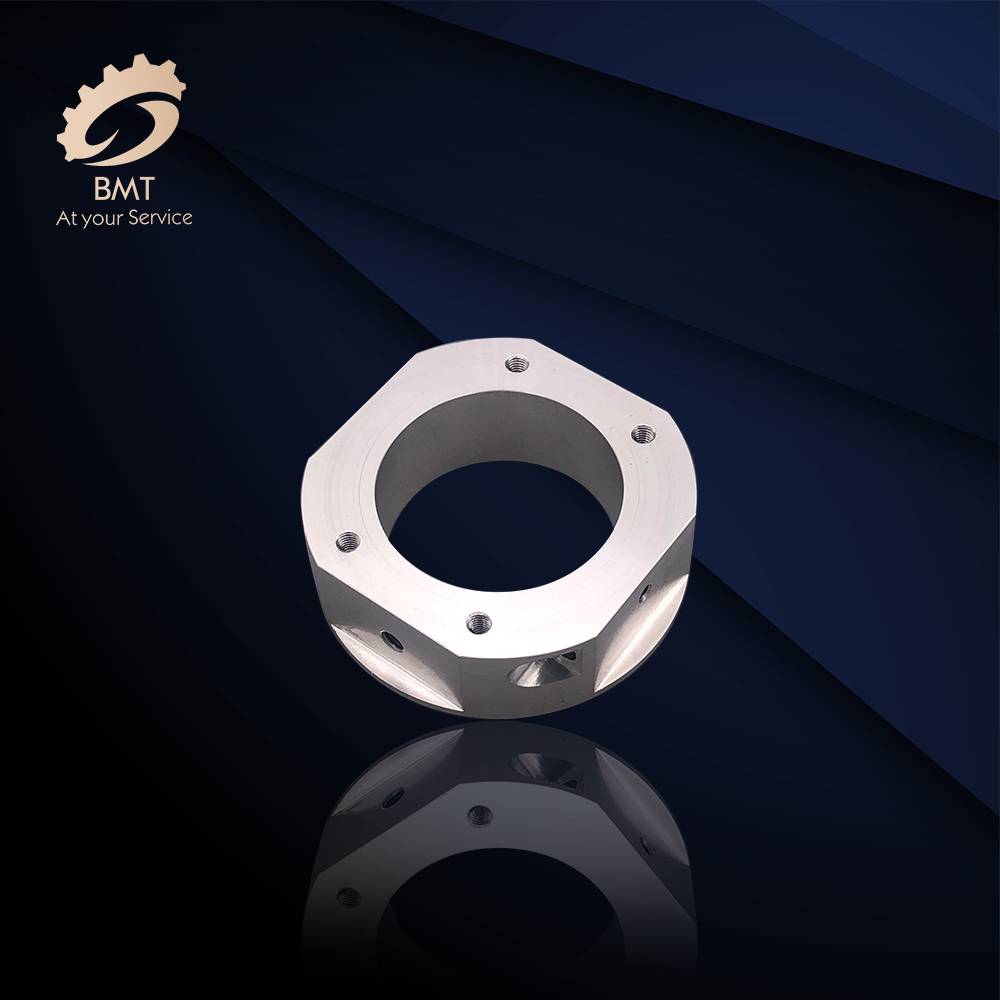

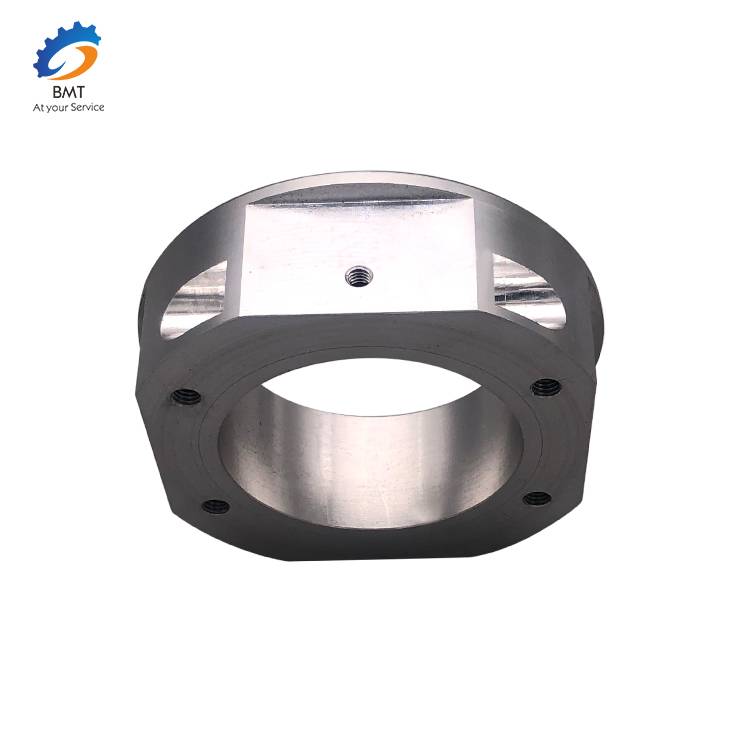

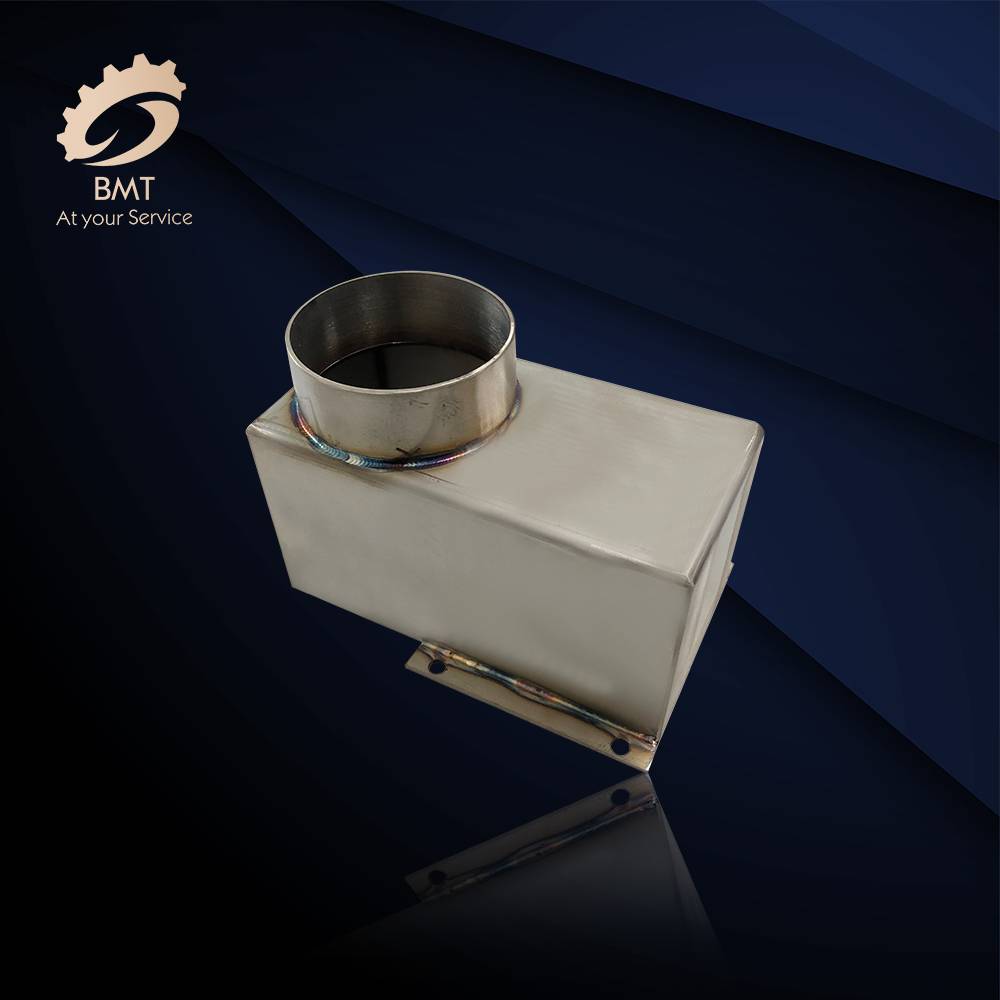

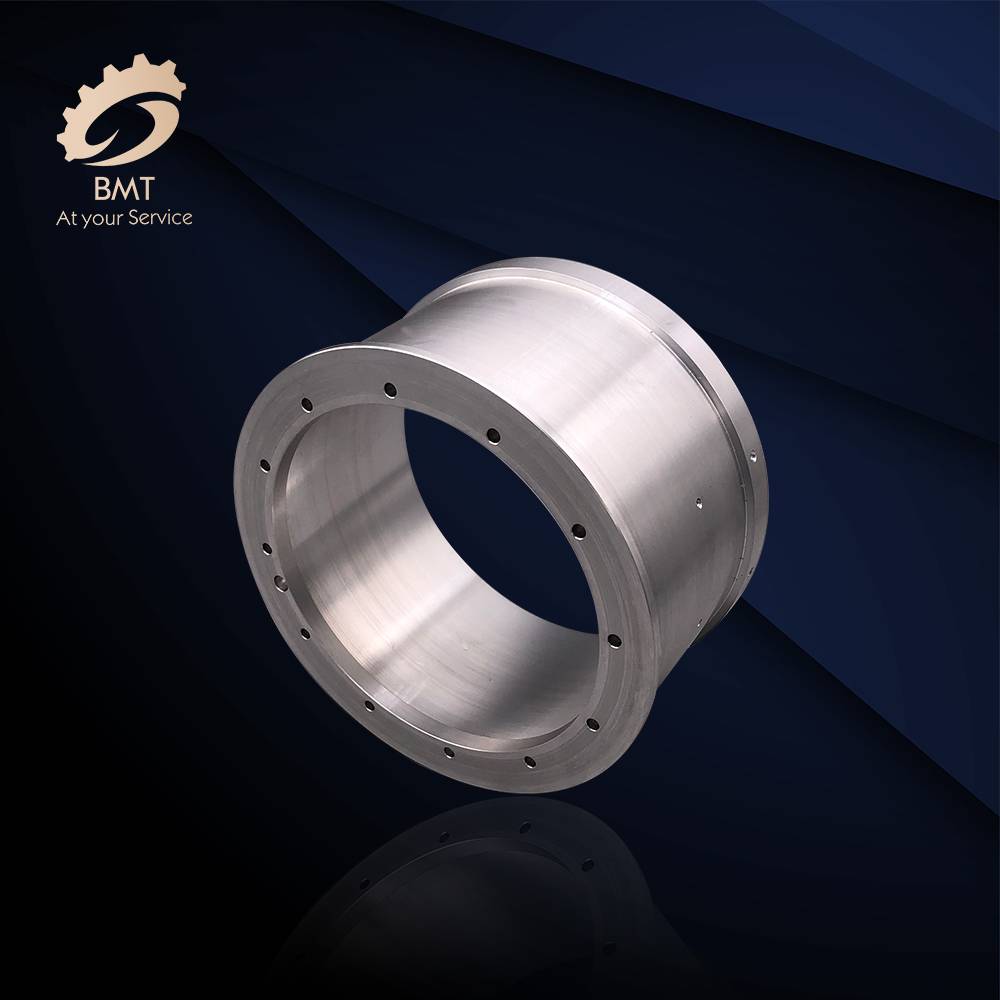

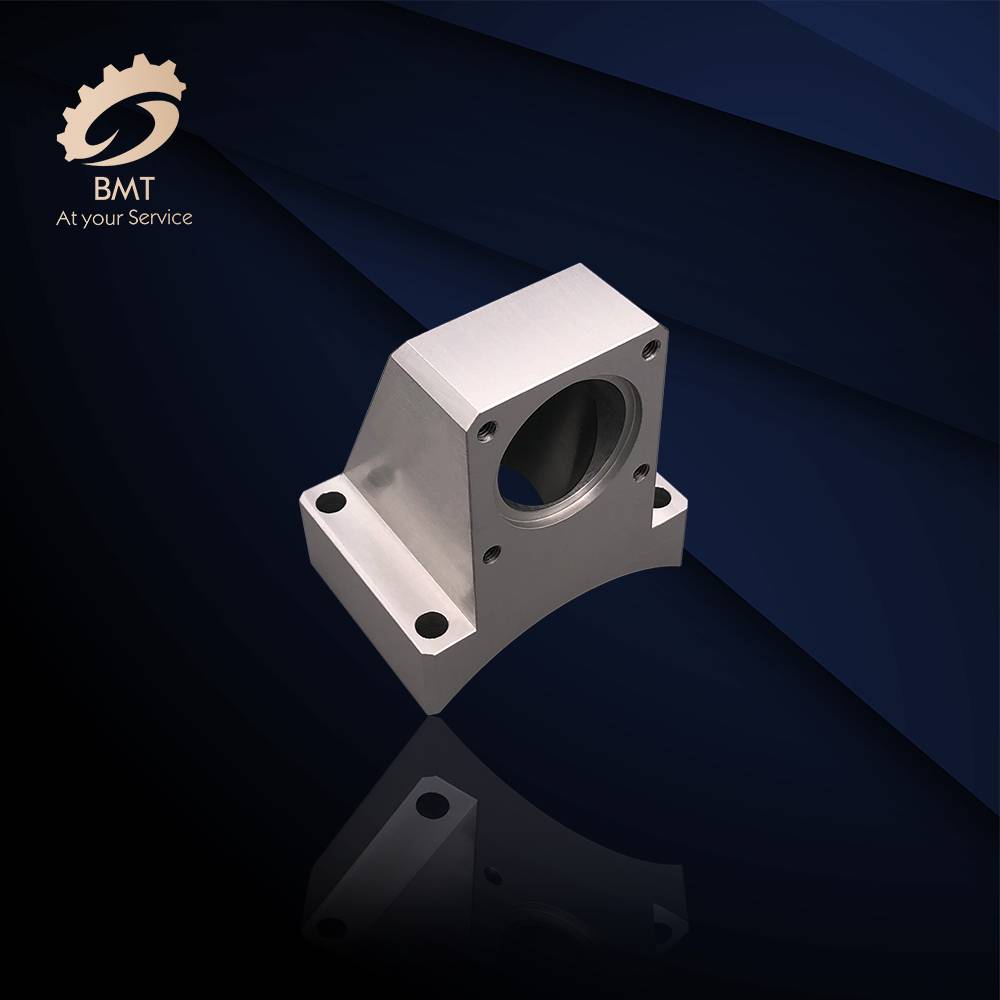

Metal CNC Services

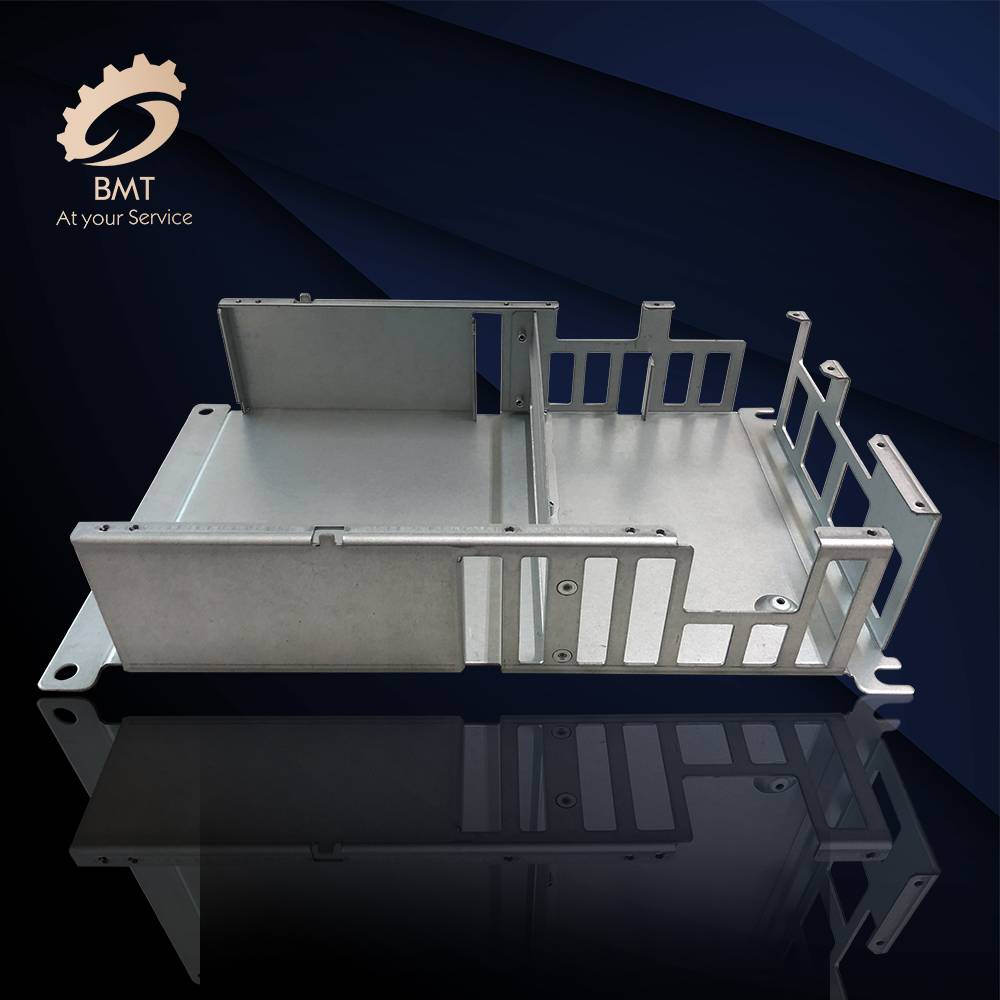

CNC Fabrication Service

CNC Mechanical Parts

Metal CNC Services

CNC Fabrication Service

CNC Mechanical Parts

BMT is proud to work with a selection of highly trusted, rigorously chosen customers. Each customer requests to offer the highest quality CNC Machined parts. By maintaining close relationships with our clients, BMT is able to offer exceptional levels of quality.

BMT commits to delivering Quality Assured CNC Machined Parts on time. It is one of the many reasons why our clients trust us with their manufacturing needs.

Trust us to deliver your CNC Machining Project on time, to specification and at a competitive price.

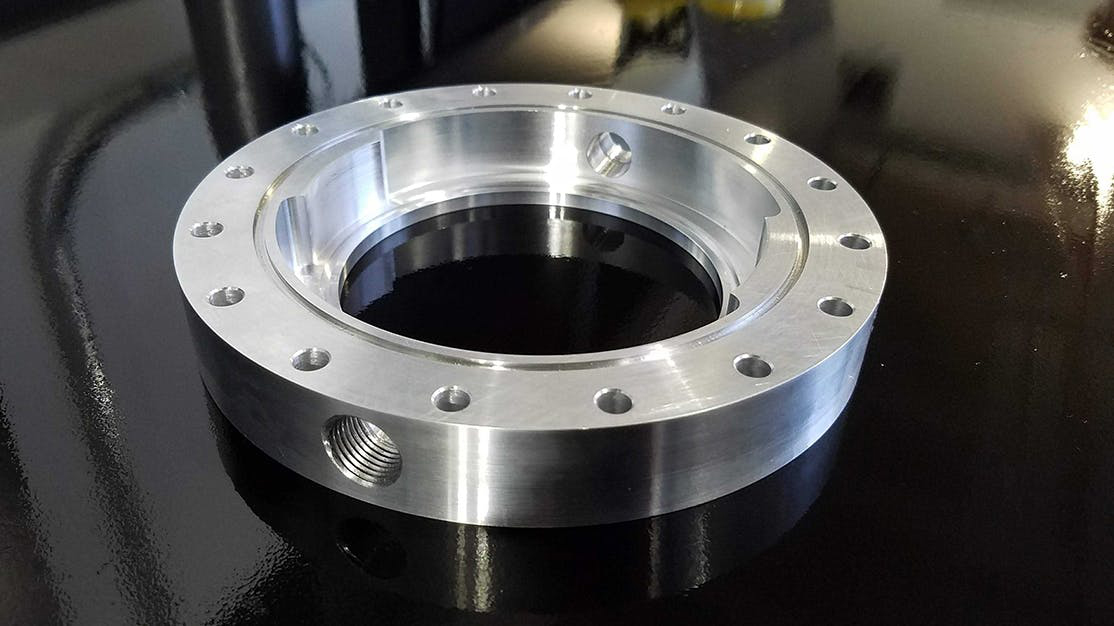

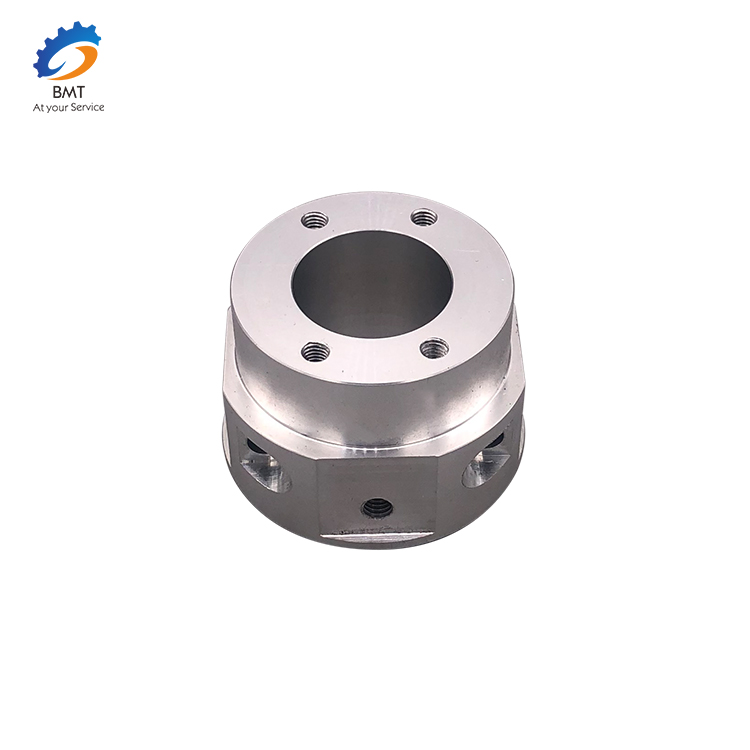

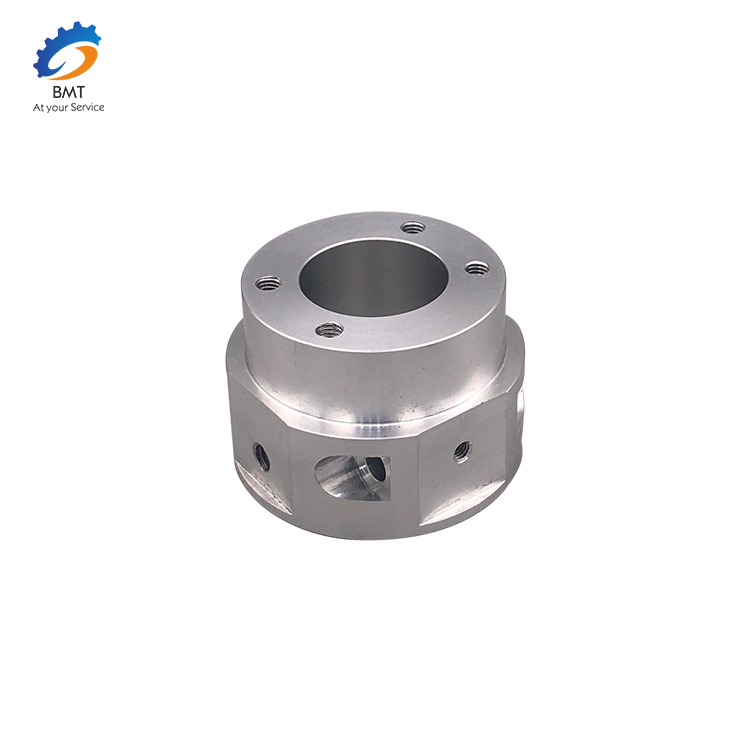

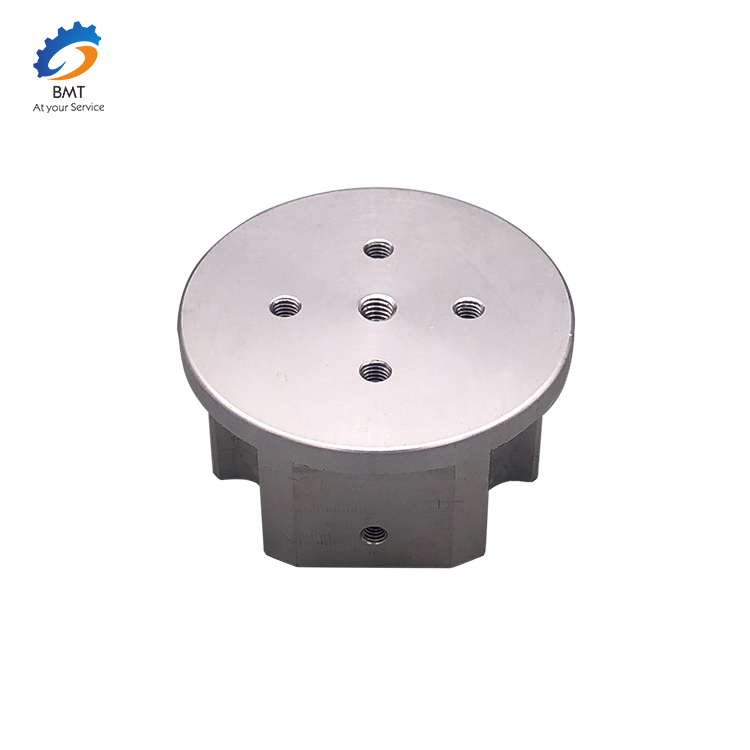

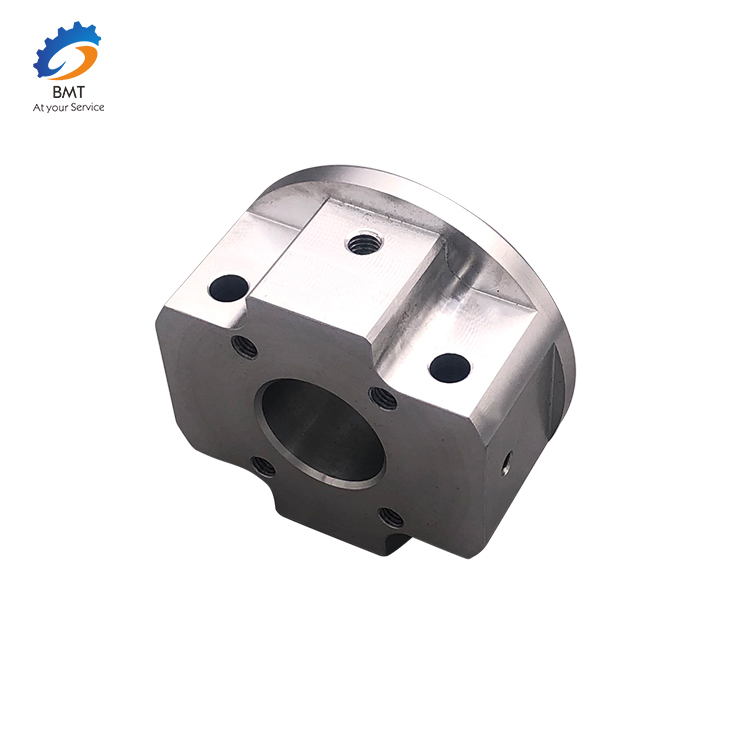

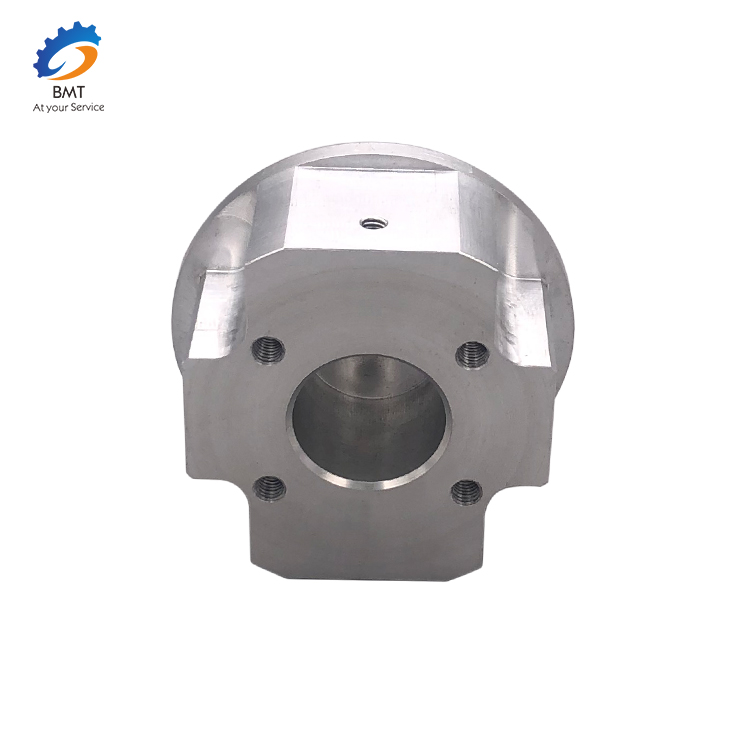

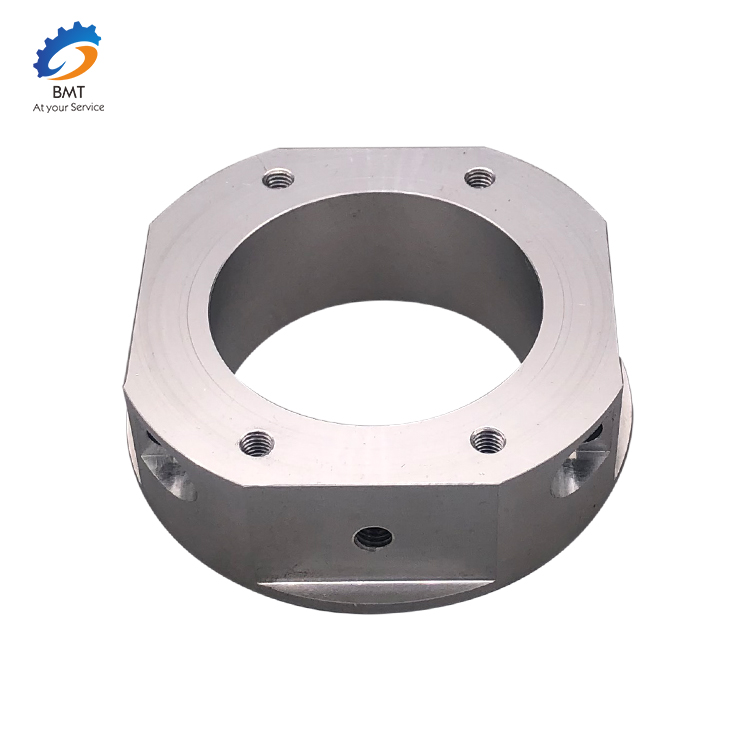

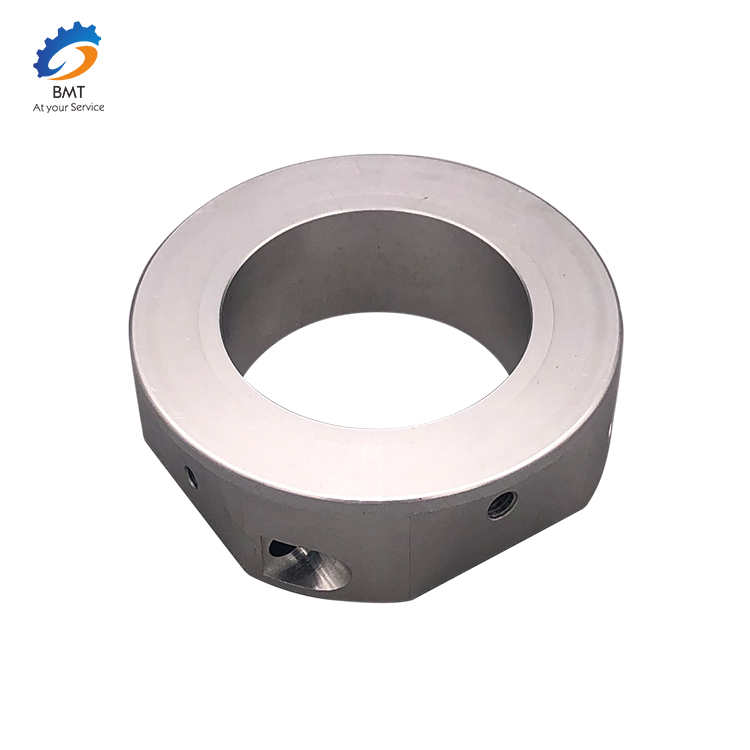

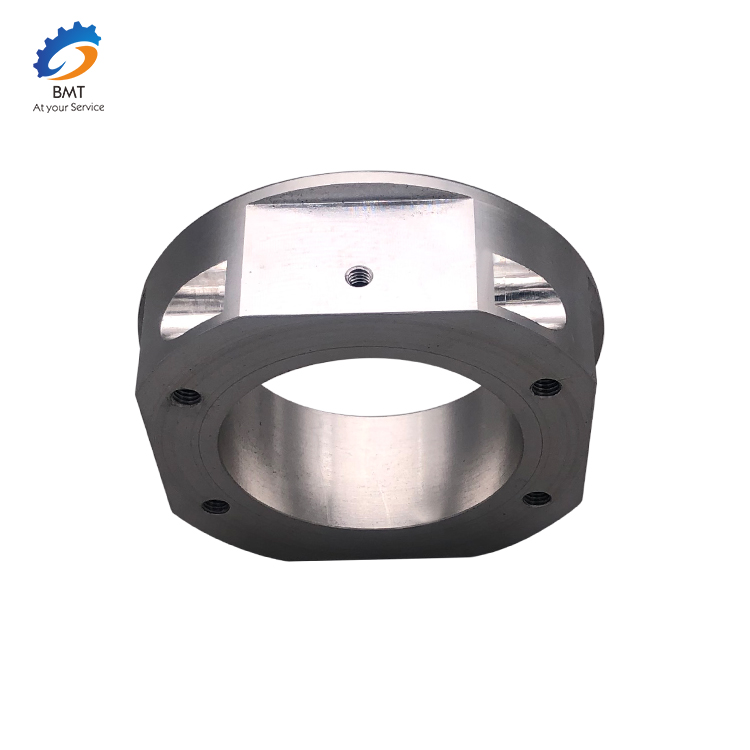

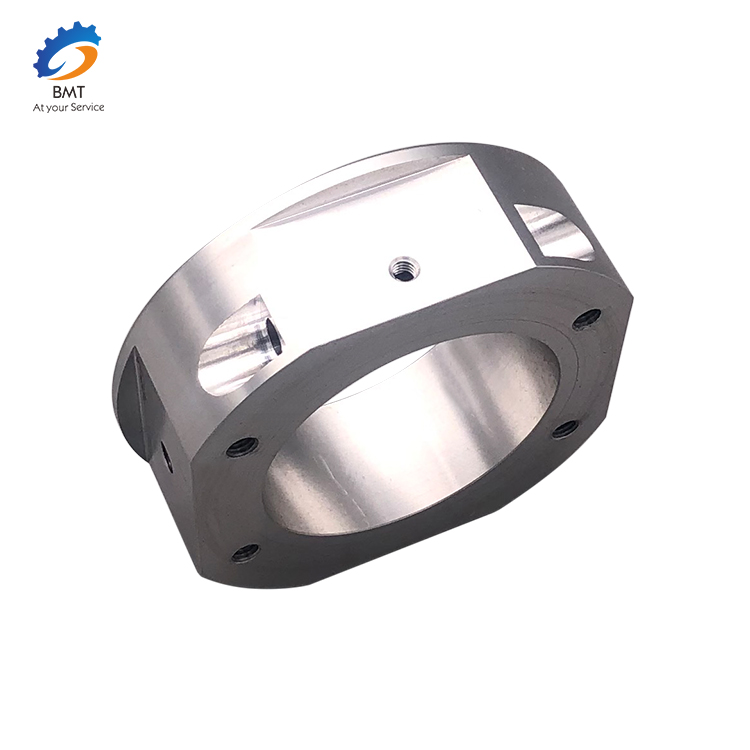

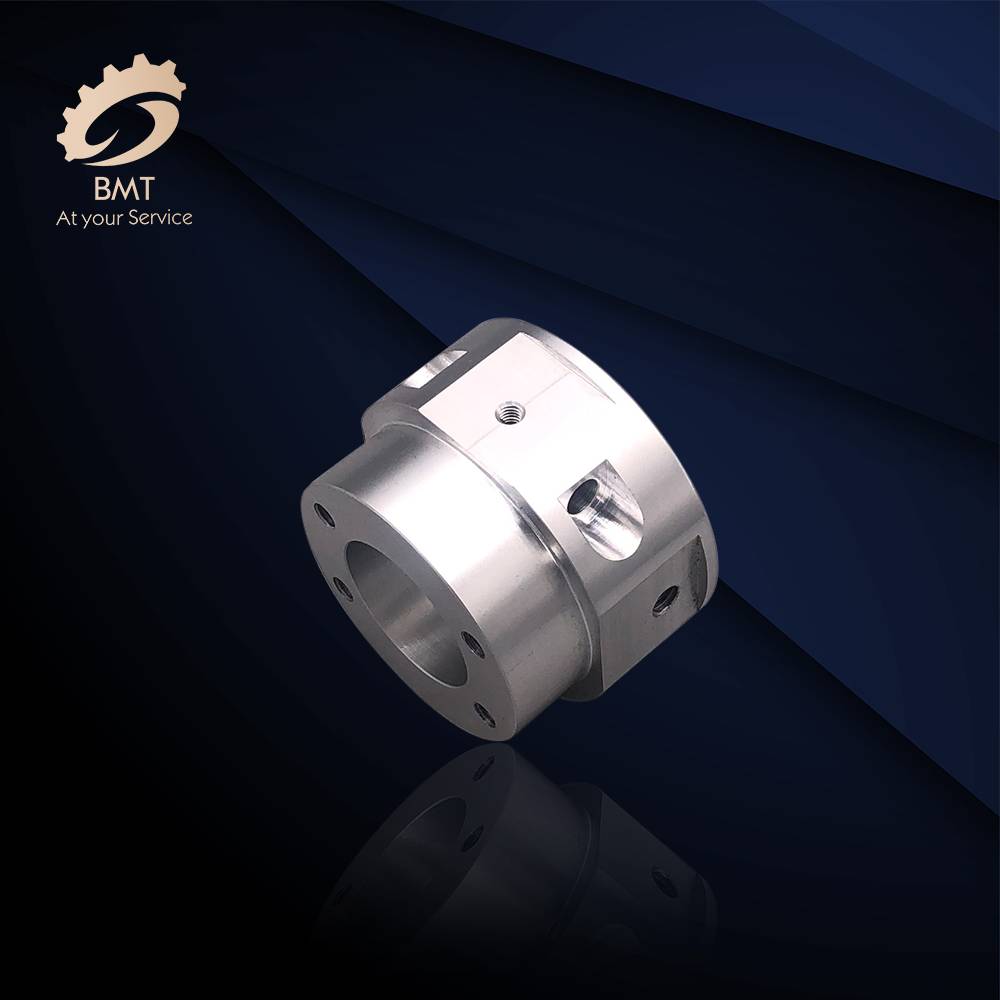

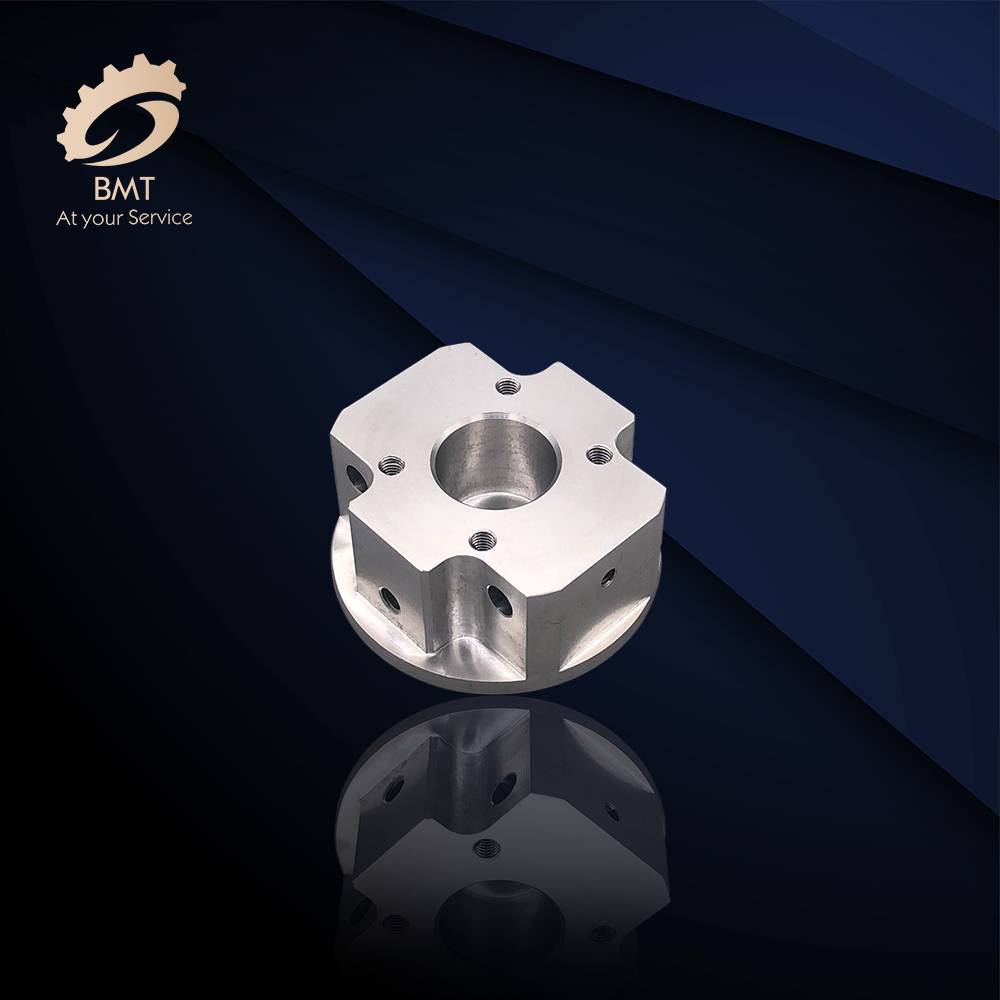

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Quality Inspection for Machined Plastic Parts - Prototype CNC Machining – Basile, The product will supply to all over the world, such as: Estonia, New Zealand, Bulgaria, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

Send your message to us:

-

Best quality Cnc Machining Service - Different...

-

PriceList for Metal Fabrication - Precision Sh...

-

Factory made hot-sale Sheet Metal And Fabricati...

-

China Manufacturer for Cnc Lathing Parts - Pre...

-

Good User Reputation for Aluminum Machined Comp...

-

Good quality Sheet Metal Auto Parts - Sheet Me...