Hot-selling Spark Cnc Services - Alpha + Beta Titanium Alloy – Basile Detail:

Titanium Alloy Welding

It is a single phase alloy composed of β-phase solid solution. Without heat treatment, it has higher strength. After quenching and aging, the alloy is advanced.One step strengthening, the room temperature strength can reach 1372 ~ 1666 MPa; But the thermal stability is poor, should not be used at high temperature.

It is a biphasic alloy, has good comprehensive properties, good structure stability, good toughness, plasticity and high temperature deformation properties, can be better for hot pressure processing, can be quenched, aging to strengthen the alloy. The strength after heat treatment is about 50% ~ 100% higher than that after annealing; High temperature strength, can work in 400℃ ~ 500℃ temperature for a long time, its thermal stability is inferior to α titanium alloy.

Among the three titanium alloys, the most commonly used are α titanium alloy and α+β titanium alloy; The cutting performance of α titanium alloy is the best, followed by α+β titanium alloy, and β titanium alloy is the worst. α titanium alloy code for TA, β titanium alloy code for TB, α+β titanium alloy code for TC.

Titanium alloy can be divided into heat resistant alloy, high strength alloy, corrosion resistant alloy (titanium – molybdenum, titanium – palladium alloy, etc.), low temperature alloy and special function alloy (titanium – iron hydrogen storage material and titanium – nickel memory alloy). The composition and properties of typical alloys are shown in the table.

Different phase compositions and microstructure of heat-treated titanium alloys can be obtained by adjusting the heat treatment process. It is generally believed that fine equiaxed structures have better plasticity, thermal stability and fatigue strength. The spiculate structure has high durability, creep strength and fracture toughness. Equiaxial and needle-like mixed tissues have better comprehensive properties. Titanium is a new type of metal, the performance of titanium is related to the content of carbon, nitrogen, hydrogen, oxygen and other impurities, the purest titanium iodide impurity content is not more than 0.1%, but its strength is low, high plasticity.

The properties of 99.5% industrial pure titanium are as follows: density ρ=4.5g/ cubic cm, melting point 1725℃, thermal conductivity λ=15.24W/(m.K), tensile strength σb=539MPa, elongation δ=25%, section shrinkage ψ=25%, elastic modulus E=1.078×105MPa, hardness HB195. The density of titanium alloy is generally about 4.51g/ cubic centimeter, only 60% of steel, the strength of pure titanium is close to the strength of ordinary steel, some high strength titanium alloy exceeds the strength of many alloy structural steel. Therefore, the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials, as shown in Table 7-1. It can produce parts and parts with high unit strength, good rigidity and light weight. Currently, titanium alloys are used in engine components, skeleton, skin, fasteners and landing gear.

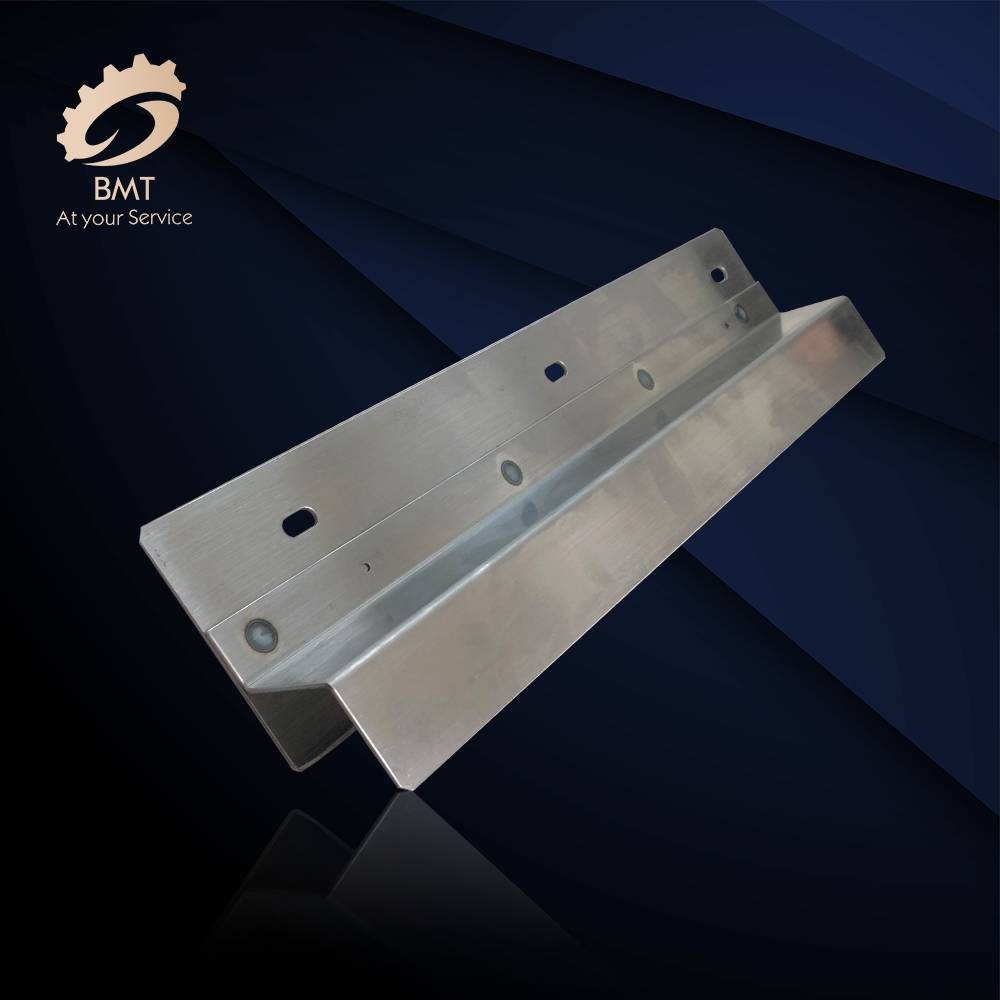

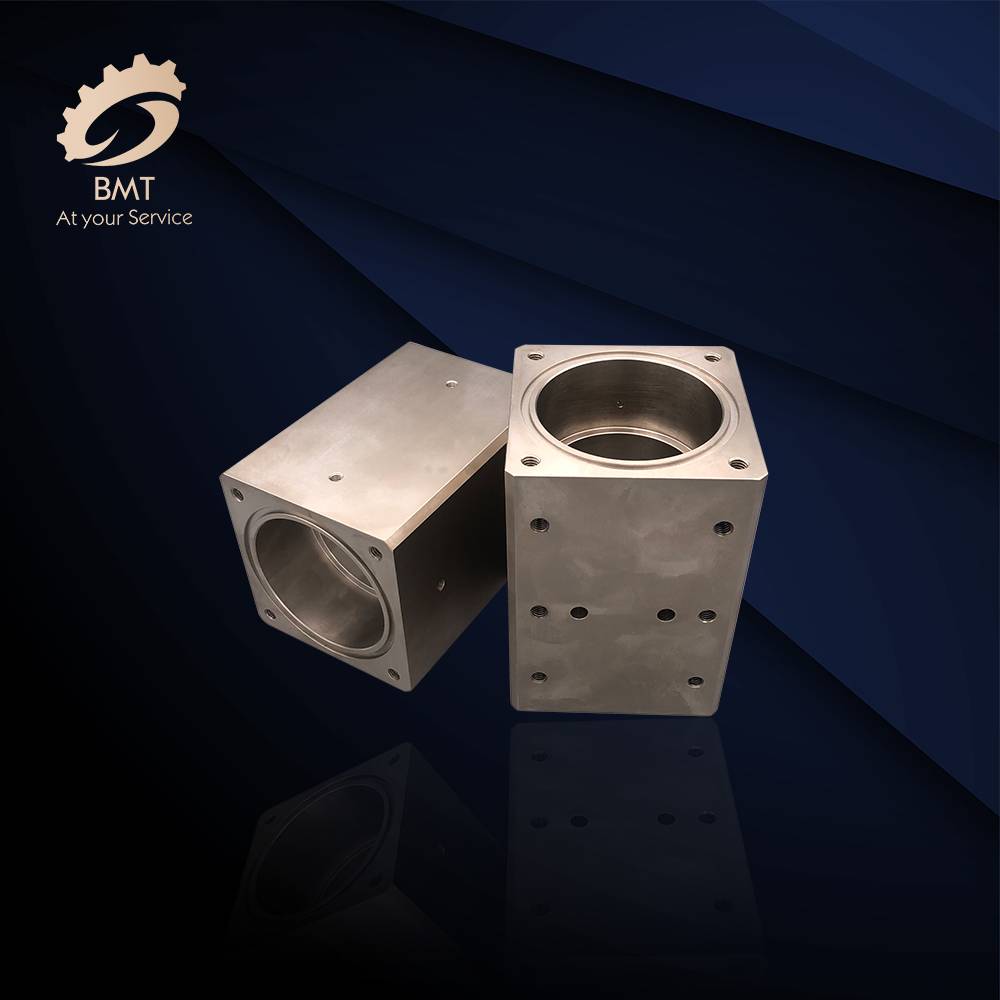

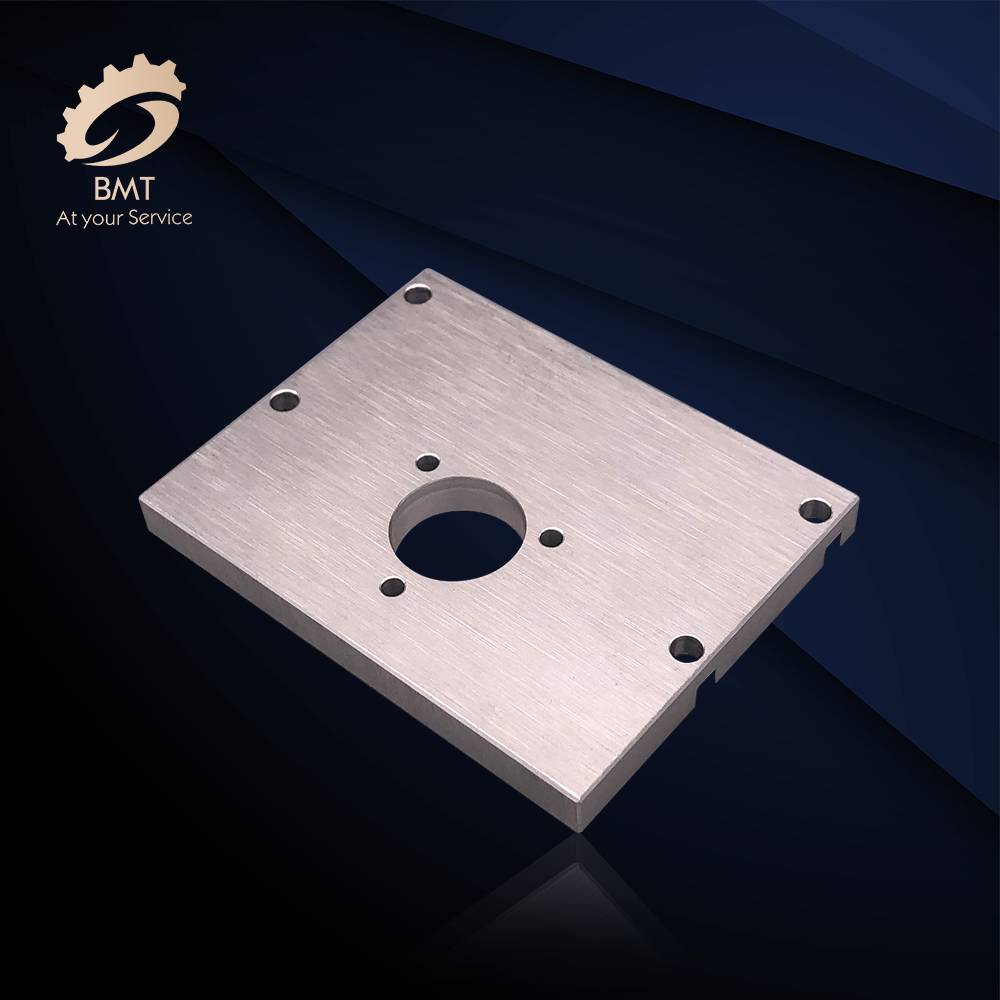

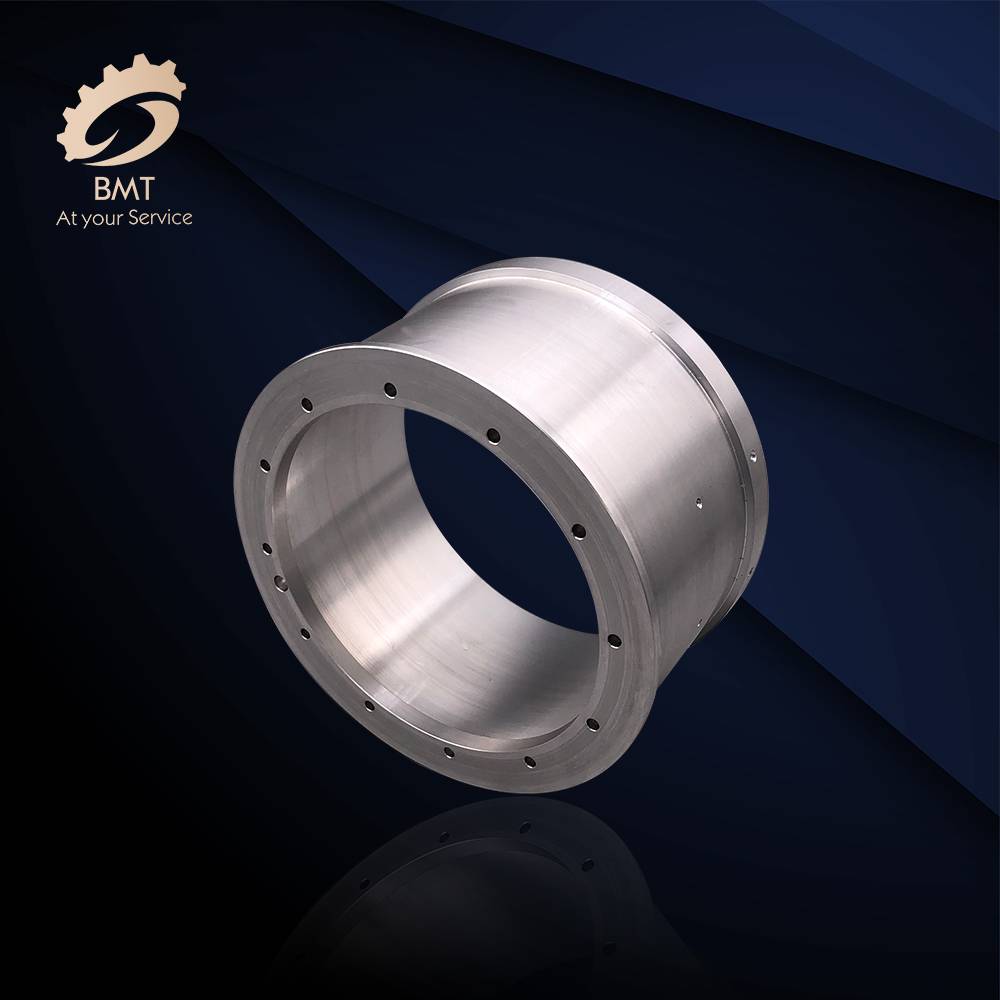

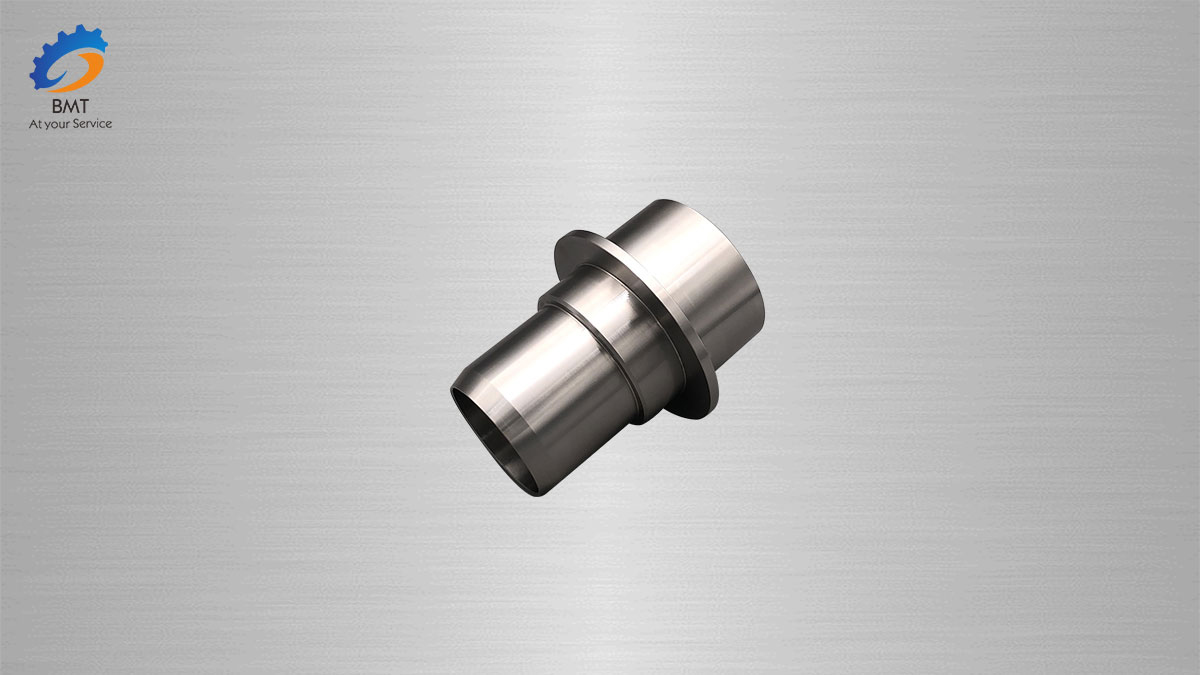

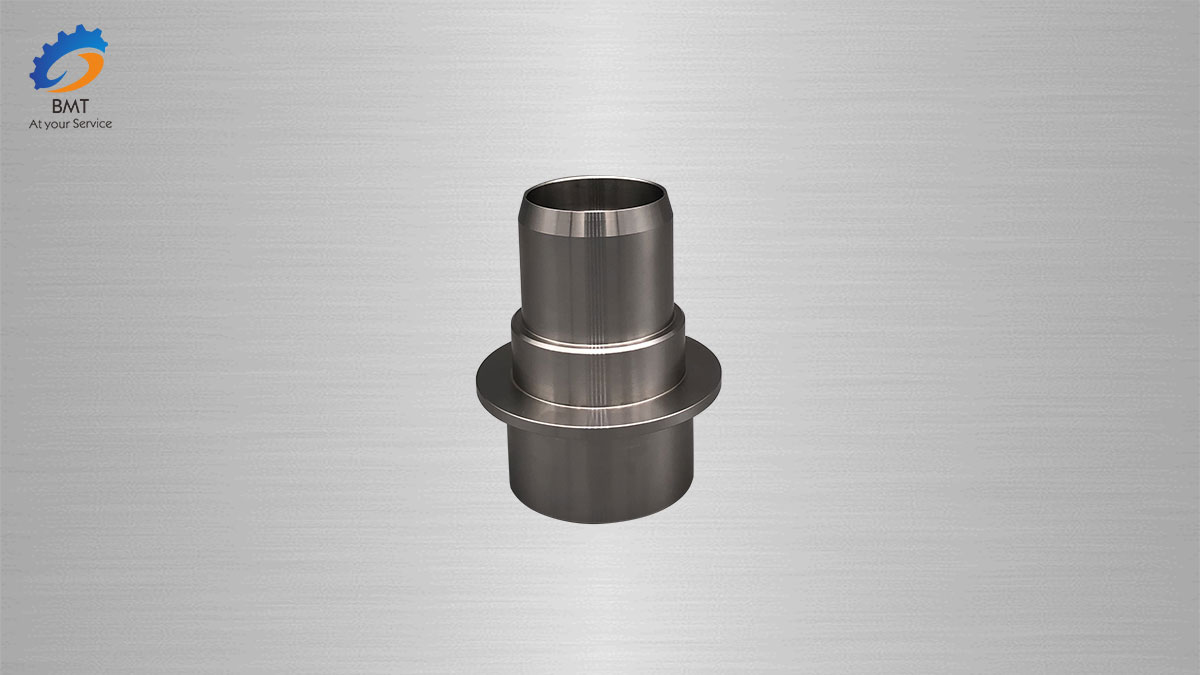

Product detail pictures:

Related Product Guide:

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for Hot-selling Spark Cnc Services - Alpha + Beta Titanium Alloy – Basile, The product will supply to all over the world, such as: Eindhoven, Manila, Moscow, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.