factory customized Aluminum Cnc Milling - Titanium Alloy CNC Machining – Basile Detail:

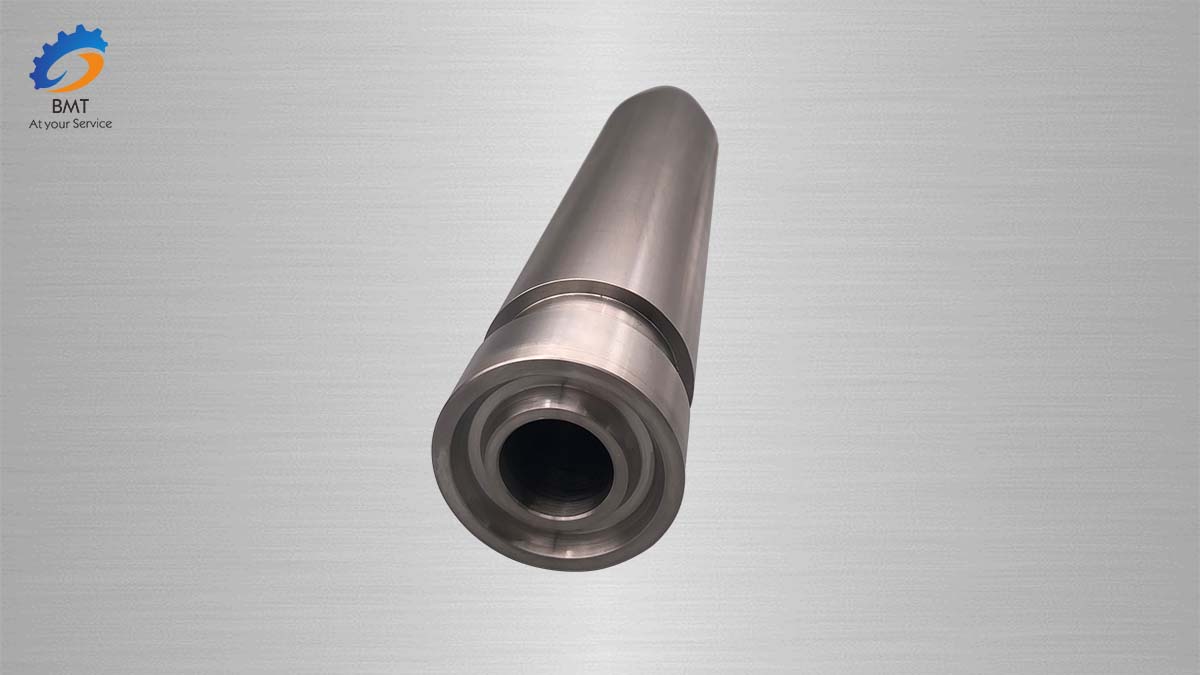

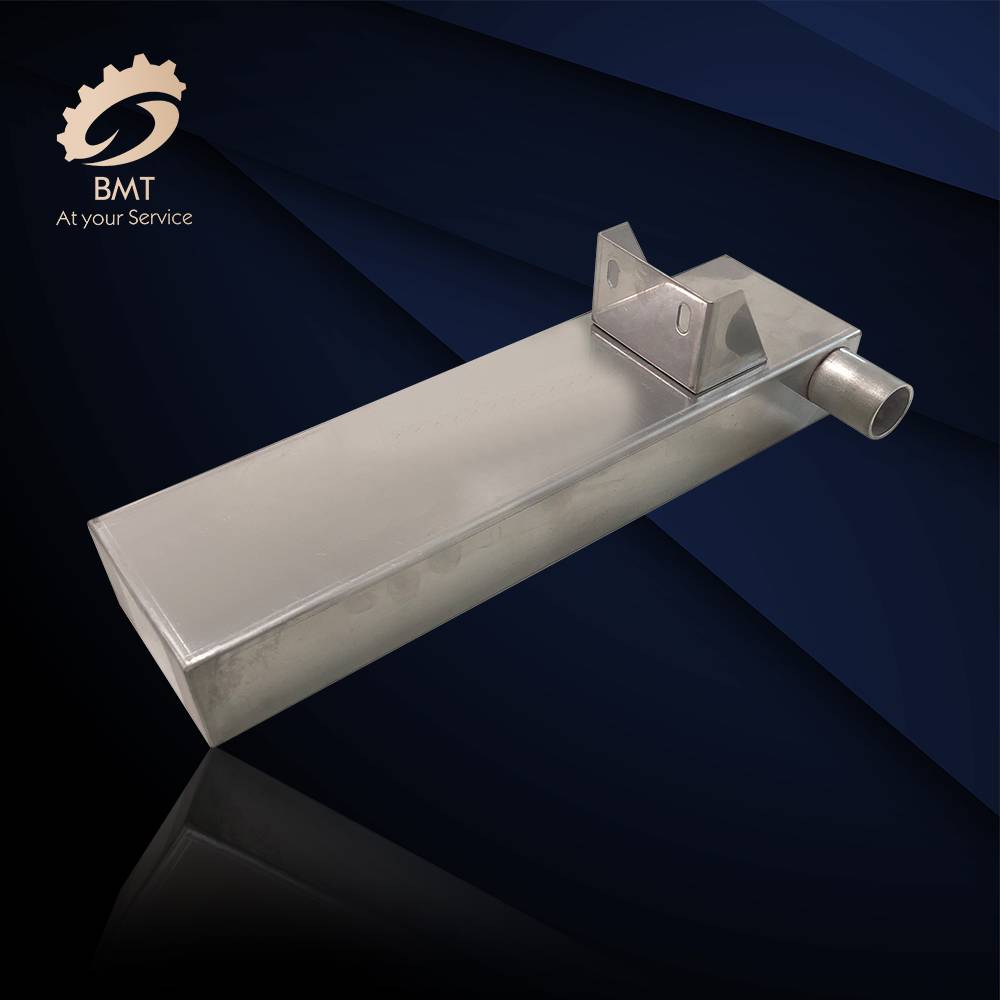

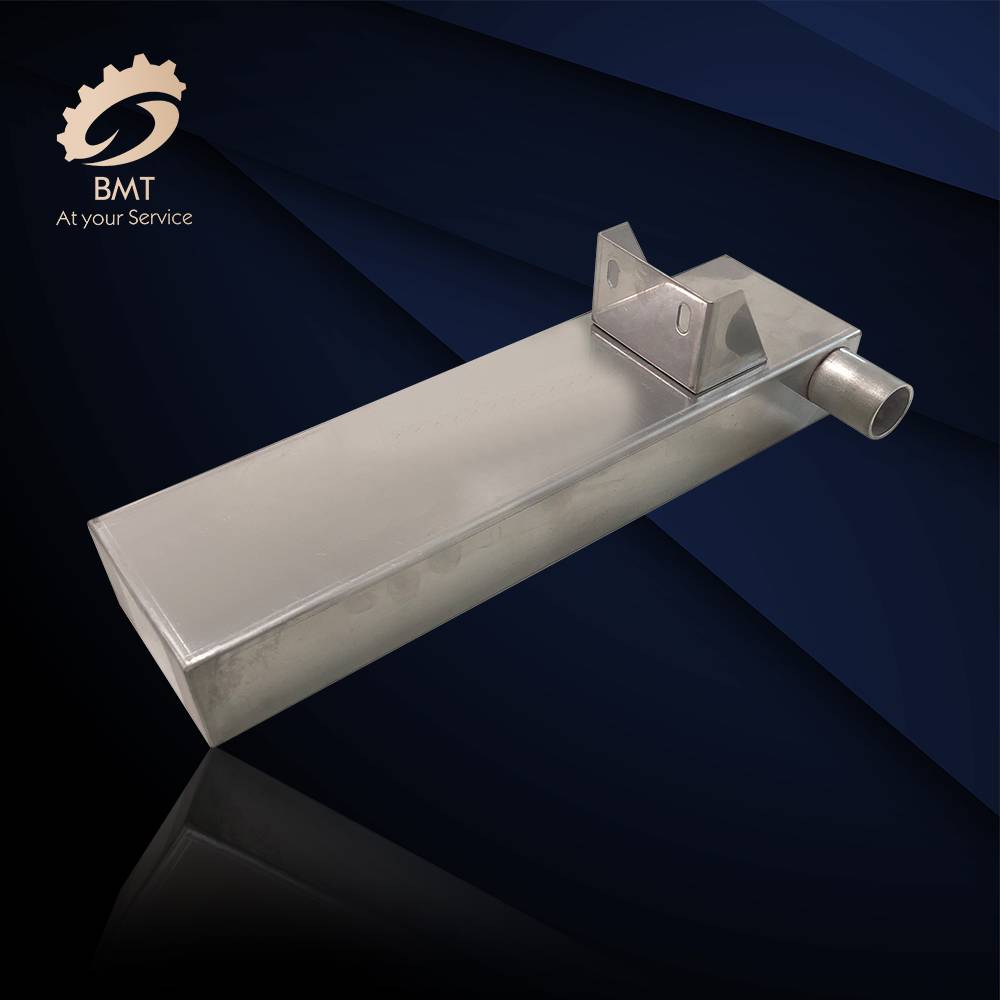

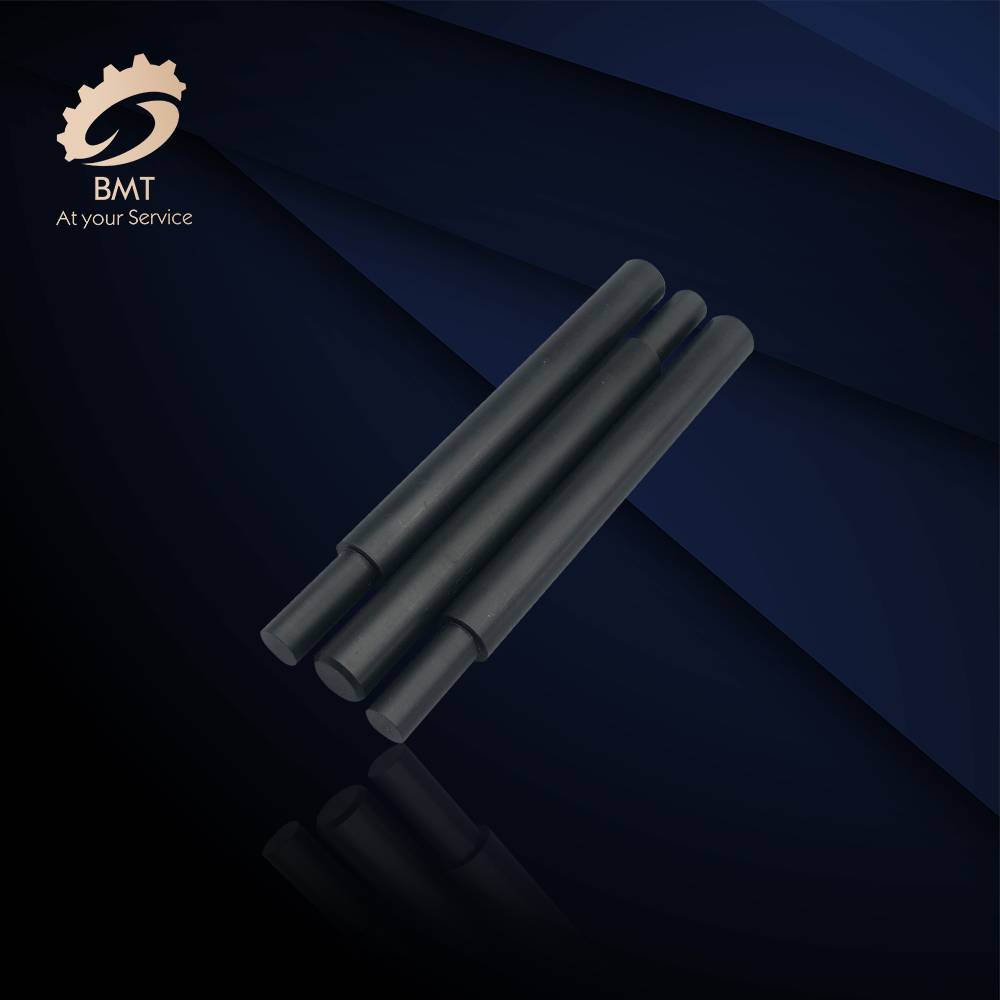

Titanium Alloy CNC Machining

Pressure machining of titanium alloys is more similar to steel machining than to non-ferrous metals and alloys. Many process parameters of titanium alloys in forging, volume stamping and sheet stamping are close to those in steel processing. But there are some important features that must be paid attention to when press working Chin and Chin alloys.

Although it is generally believed that the hexagonal lattices contained in titanium and titanium alloys are less ductile when deformed, various press working methods used for other structural metals are also suitable for titanium alloys. The ratio of yield point to strength limit is one of the characteristic indicators of whether the metal can withstand plastic deformation. The larger this ratio, the worse the plasticity of the metal. For industrially pure titanium in the cooled state, the ratio is 0.72-0.87, compared to 0.6-0.65 for carbon steel and 0.4-0.5 for stainless steel.

Carry out volume stamping, free forging and other operations related to the processing of large cross-section and large size blanks in the heated state (above the =yS transition temperature). The temperature range of forging and stamping heating is between 850-1150°C. Alloys BT; M0, BT1-0, OT4~0 and OT4-1 have satisfactory plastic deformation in the cooled state. Therefore, the parts made of these alloys are mostly made of intermediate annealed blanks without heating and stamping. When the titanium alloy is cold plastically deformed, regardless of its chemical composition and mechanical properties, the strength will be greatly improved, and the plasticity will be correspondingly reduced. For this reason, annealing treatment between processes must be performed.

The wear of the insert groove in the machining of titanium alloys is the local wear of the back and front in the direction of the depth of cut, which is often caused by the hardened layer left by the previous processing. The chemical reaction and diffusion of the tool and the workpiece material at a processing temperature of more than 800 °C are also one of the reasons for the formation of groove wear. Because during the machining process, the titanium molecules of the workpiece accumulate in the front of the blade and are “welded” to the blade edge under high pressure and high temperature, forming a built-up edge. When the built-up edge peels off the cutting edge, the carbide coating of the insert is taken away.

Due to the heat resistance of titanium, cooling is crucial in the machining process. The purpose of cooling is to keep the cutting edge and tool surface from overheating. Use end coolant for optimum chip evacuation when performing shoulder milling as well as face milling pockets, pockets or full grooves. When cutting titanium metal, the chips are easy to stick to the cutting edge, causing the next round of milling cutter to cut the chips again, often causing the edge line to chip.

Each insert cavity has its own coolant hole/injection to address this issue and enhance constant edge performance. Another neat solution is threaded cooling holes. Long edge milling cutters have many inserts. Applying coolant to each hole requires a high pump capacity and pressure. On the other hand, it can plug unneeded holes as needed, thereby maximizing flow to the holes that are needed.

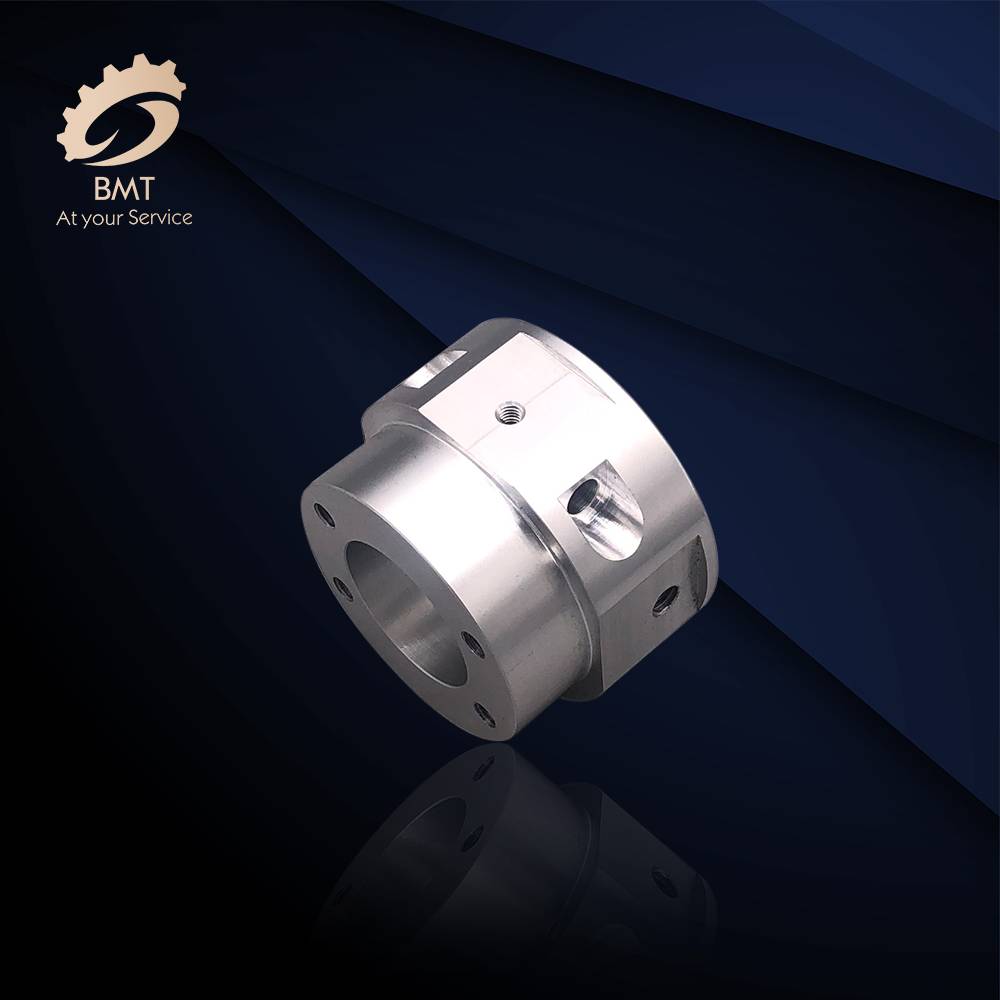

Product detail pictures:

Related Product Guide:

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for factory customized Aluminum Cnc Milling - Titanium Alloy CNC Machining – Basile, The product will supply to all over the world, such as: Honduras, Poland, Belgium, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.

Send your message to us:

-

OEM Supply Metal Box Fabrication - Sheet Metal...

-

New Delivery for 5 Axis Parts - CNC Milling Ma...

-

Factory Cheap Hot Sheet Metal Forming Companies...

-

Reasonable price for Cnc Milling Turning - Cus...

-

Bottom price Cnc Aluminum Parts - Your Custom ...

-

8 Year Exporter Contract Cnc Machining - Proto...