Factory Cheap Cnc Machining Services Inc - Influence Of Cutting Heat – Basile Detail:

Influence Of Cutting Heat

When milling nickel-based alloys, a large amount of cutting heat is generated. Therefore, when machining, apply sufficient coolant to submerge the cutting area, which is easy to achieve for small-diameter milling cutters, but for large-diameter tools (such as face milling cutters), it is impossible to completely submerge during cutting, and the coolant can only be turned off , using dry milling.

When the milling cutter cannot be covered by the coolant, the heat is rapidly transferred to and from the insert, resulting in many small cracks perpendicular to the cutting edge, and the cracks gradually expand, eventually causing the cemented carbide to break. In some cases, a smaller milling cutter can be used, and no coolant is required for machining. If the tool cuts normally and the tool life is improved, it means that effective dry milling can also be performed.

Because parts in the medical and aerospace industries are often made of nickel-based alloys, this material is usually accompanied by certification documents, in which the chemical structure of this special material is given, so that we can know when milling is milling. what material. What should be paid attention to is how to select appropriate cutting parameters and cutting methods according to the composition of such materials.

As mentioned earlier, the two main elements of this group of metals are nickel and chromium. When a metal smelter adjusts the percentage content of each metal, its properties such as corrosion resistance, strength, hardness, etc. change, as does its machinability.

Designing a tool to cut tough or hard workpieces is not difficult, but designing a nickel-based alloy tool that does both is not. You may have your own name for these alloys, but as long as you know their composition and use the appropriate tool, you can mill materials like Corp20, Rene41, and Haynes242 without a hitch.

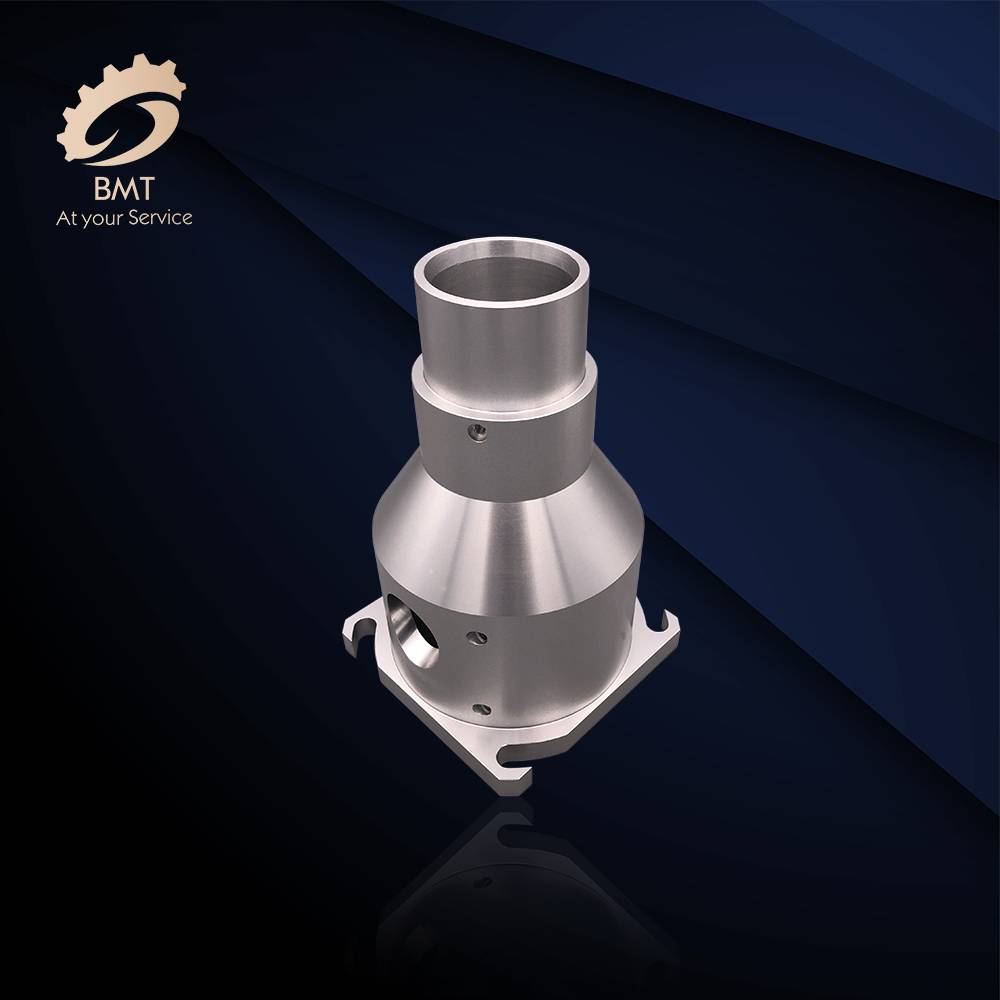

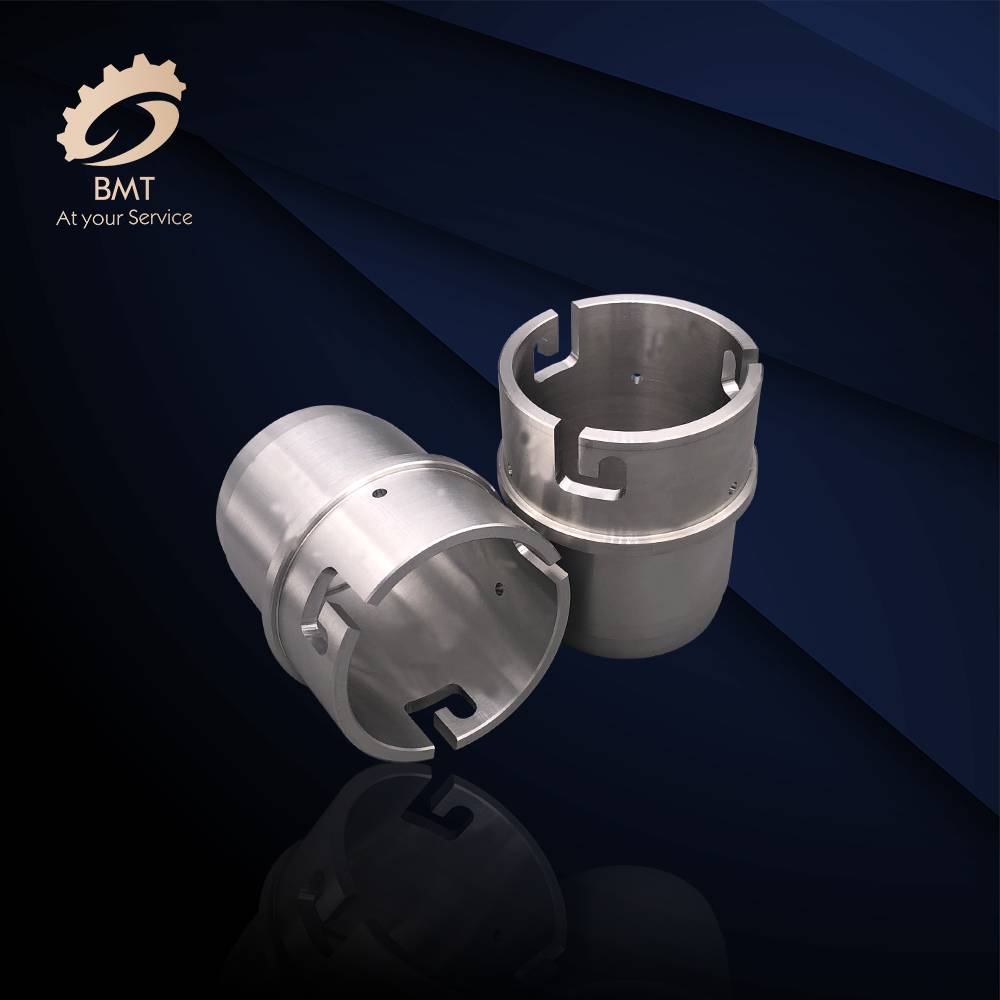

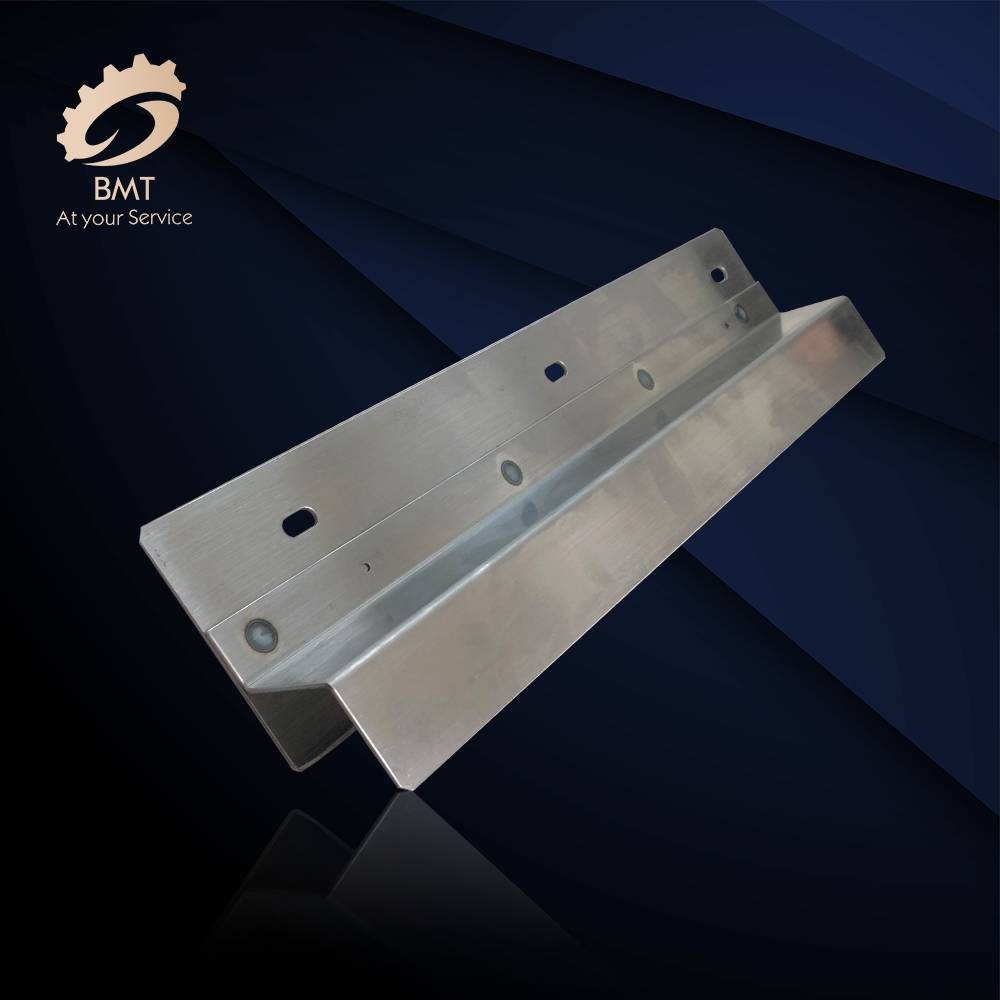

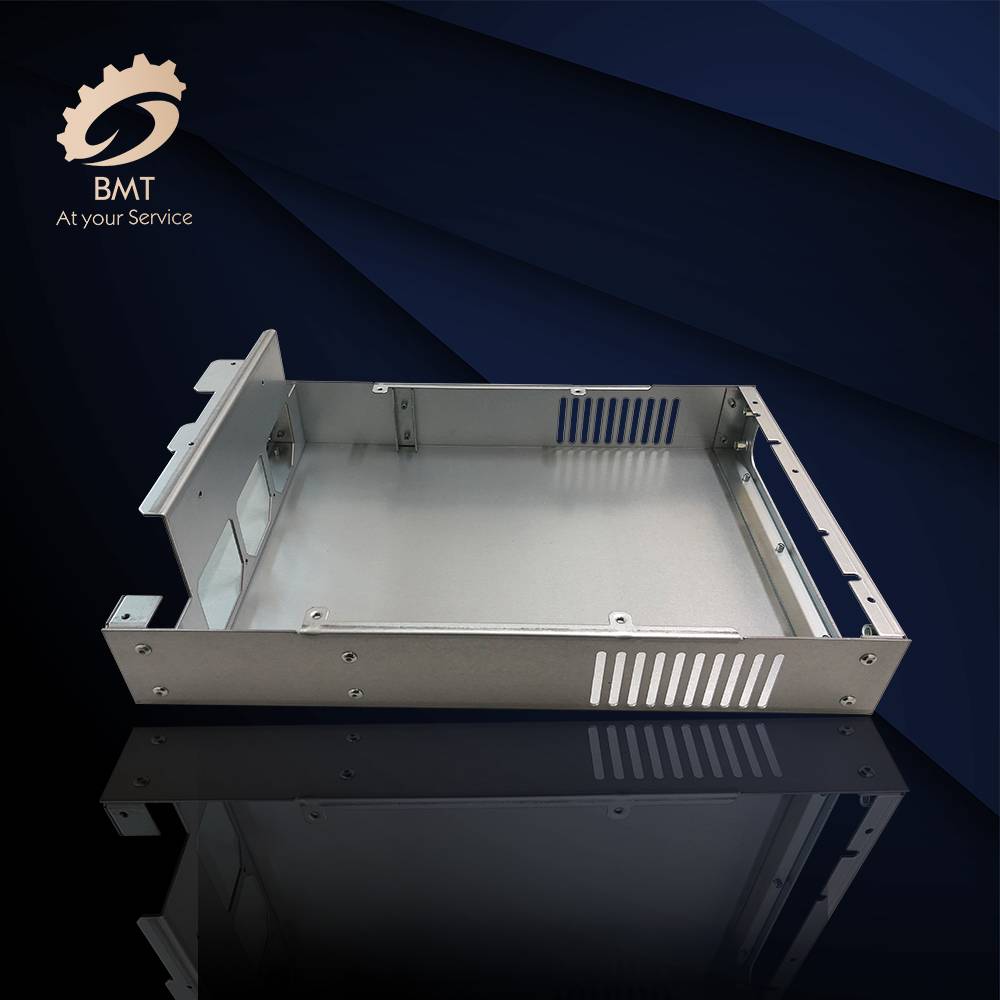

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Factory Cheap Cnc Machining Services Inc - Influence Of Cutting Heat – Basile, The product will supply to all over the world, such as: Suriname, Milan, Oman, With the first-class products, excellent service, fast delivery and the best price, we have won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Send your message to us:

-

Hot sale Factory Cnc Build Parts - CNC Milling...

-

OEM Customized Aluminum Cnc Milling Parts - CN...

-

Reasonable price Stamped Sheet Metal Parts - A...

-

Lowest Price for Brass And Aluminum Cnc Machini...

-

Top Suppliers Round Duct Fabrication - Industr...

-

Good Quality Sheet Metal And Stamping Parts - ...