Chinese Professional Oem Cnc Machining Turning Parts - How are These Thin-Walled Parts Produced? – Basile Detail:

How are These Thin-Walled Parts Produced?

Metal spinning is a symmetrical rotational forming process for sheet metal. The spindle drives the blank and the mold core to rotate, and then the rotary wheel applies pressure to the rotating blank. Due to the rotary motion of the main shaft of the spinning machine and the longitudinal and transverse feed motion of the tool, this local plastic deformation gradually expands to the entire blank, thereby obtaining various shapes of hollow rotating body parts.

Process cost: mold cost (low), single piece cost (medium)

Typical products: furniture, lamps, aerospace, transportation, tableware, jewelry, etc.

Yield suitable: small and medium batch production

Surface Quality:

Surface quality is largely dependent on operator skill and production speed

Machining speed: Moderate to high production speed, depending on part size, complexity and sheet metal thickness

Applicable materials:

Suitable for warm metal sheets such as stainless steel, brass, copper, aluminum, titanium, etc.

Design Considerations:

1. Metal spinning is only suitable for the manufacture of rotationally symmetrical parts, and the most ideal shape is hemispherical thin-shell metal parts;

2. For parts formed by metal spinning, the internal diameter should be controlled within 2.5m.

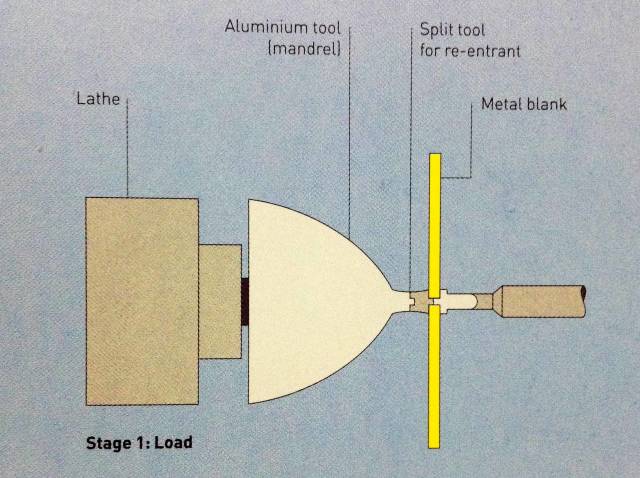

Step 1: Fix the cut round metal sheet on the machine mandrel.

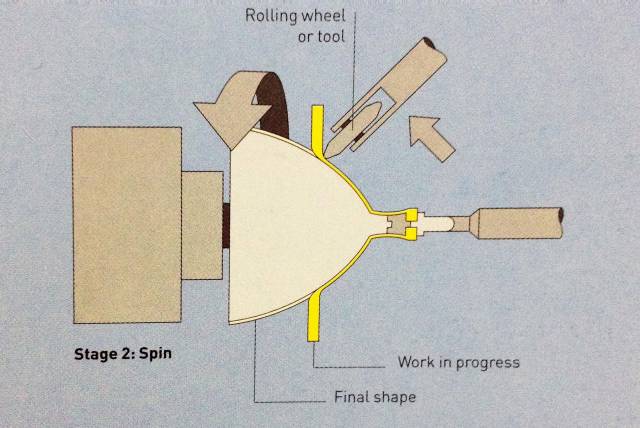

Step 2: The mandrel drives the circular metal plate to rotate at a high speed, and the tool with the runner begins to press the metal surface until the metal plate completely fits the inner wall of the mold.

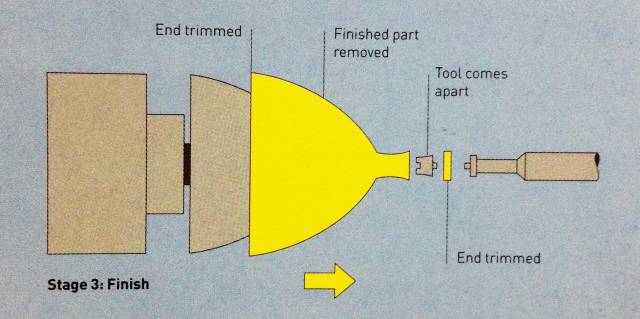

Step 3: After molding is complete, the mandrel is removed and the top and bottom of the part are cut off for demolding.

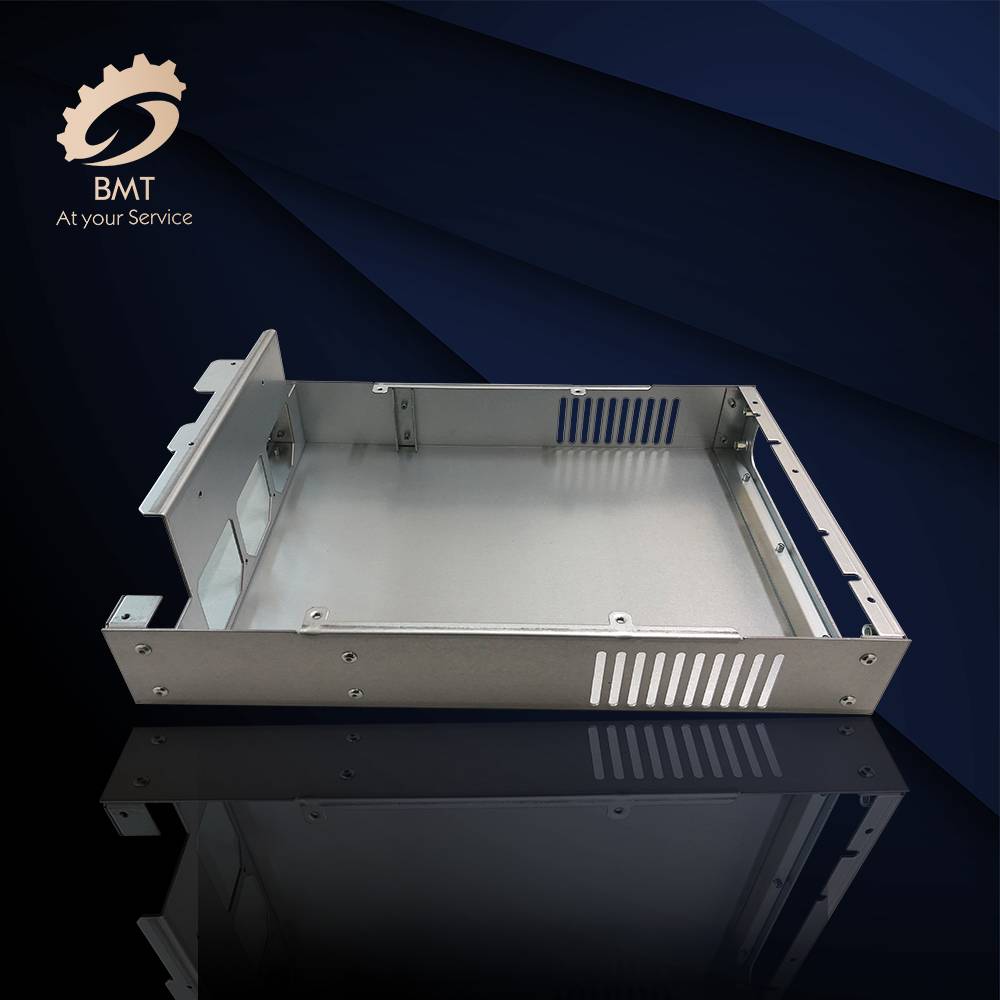

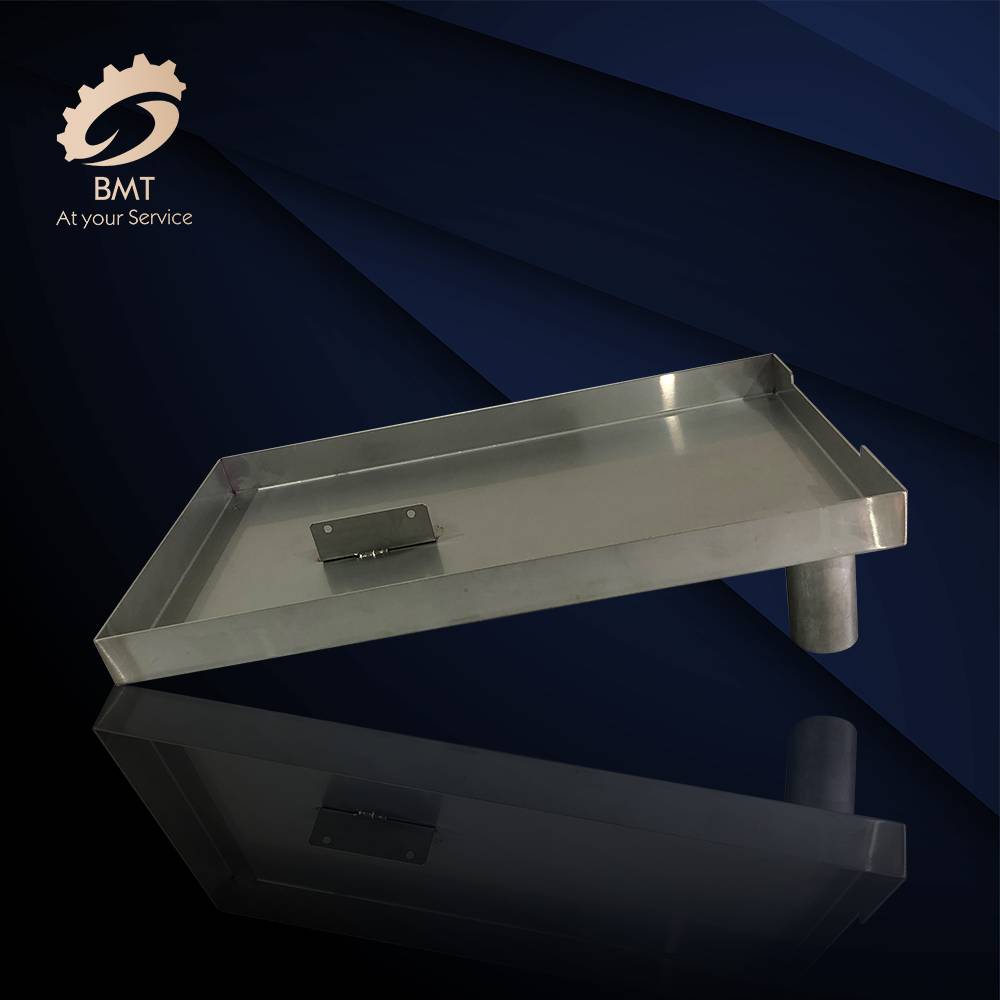

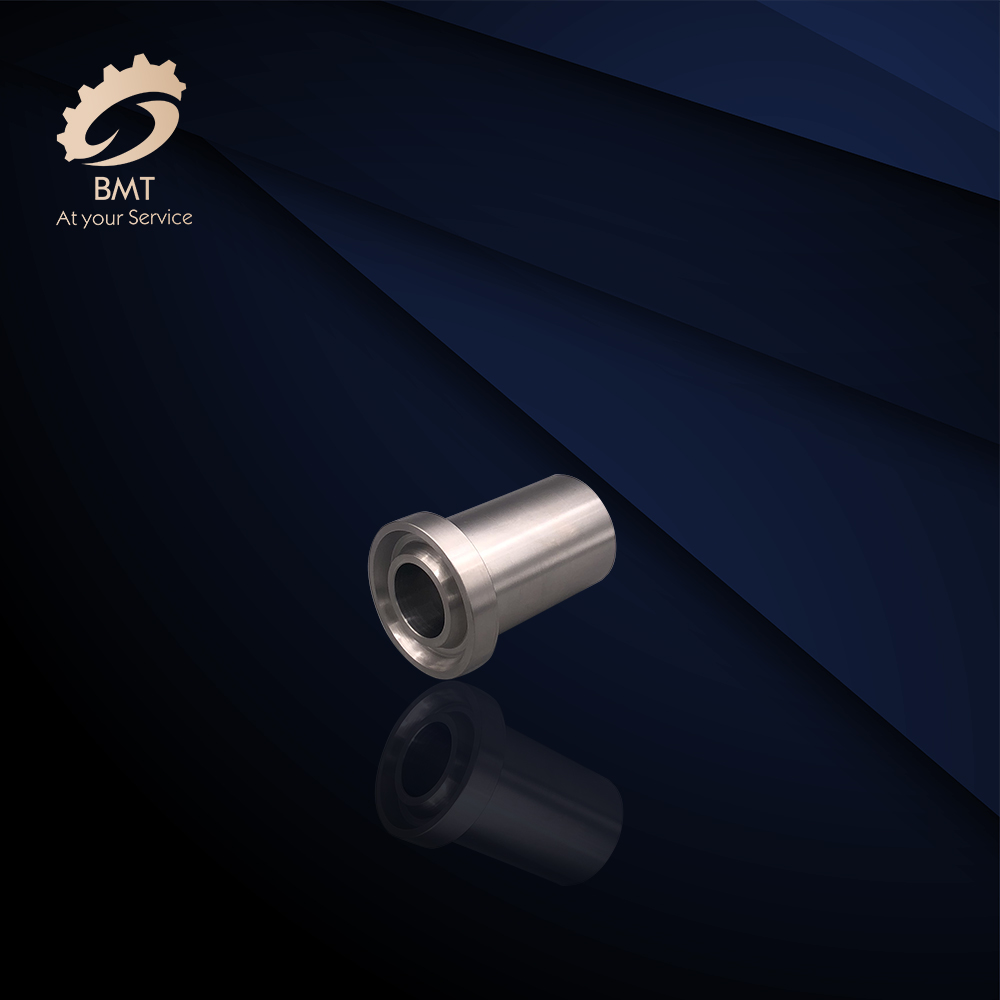

Product detail pictures:

Related Product Guide:

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Chinese Professional Oem Cnc Machining Turning Parts - How are These Thin-Walled Parts Produced? – Basile, The product will supply to all over the world, such as: Guatemala, Zambia, Australia, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we've insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!