2021 New Style Cnc Lathe Machining - CNC Machining Civilized Production and Safe Operating Procedures – Basile Detail:

CNC Machining Operational Safety

Civilized Production

CNC machine tools are advanced processing equipment with a high degree of automation and complex structure. In order to give full play to the superiority of the machine tools, improve production efficiency, manage, use, and repair CNC machine tools, the quality of technicians and civilized production are particularly important. . In addition to being familiar with the performance of CNC machine tools, operators must also develop good working habits and rigorous work styles in civilized production, and have good professional qualities, sense of responsibility and spirit of cooperation. The following points should be done during operation:

(1) Strictly abide by the safe operation regulations of CNC machine tools. Do not operate the machine without professional training.

(2) Strictly abide by the commuting and shifting system.

(3) Use and manage the machine well, and have a strong sense of work responsibility.

(4) Keep the environment around the CNC machine tool clean and tidy.

(5) Operators should wear work clothes and work shoes, and no dangerous clothing items should be worn or worn.

Safety Operating Procedures

In order to use the CNC machine tool correctly and reasonably, reduce the incidence of its failure, the operation method. The machine tool can only be operated with the consent of the machine tool manager.

(1) Precautions before Starting Up

1) The operator must be familiar with the performance and operation methods of the CNC machine tool. The machine tool can only be operated with the consent of the machine tool manager.

2) Before powering on the machine tool, check whether the voltage, air pressure, and oil pressure meet the working requirements.

3) Check whether the movable part of the machine tool is in a normal working state.

4) Check whether there is an offside or limit state on the workbench.

5) Check whether the electrical components are firm and whether the wiring is off.

6) Check whether the ground wire of the machine tool is reliably connected to the ground wire of the workshop (especially important for the first startup).

7) Turn on the main power switch only after the preparations before starting the machine have been completed.

(2) Precautions during the Boot Process

1) Operate strictly in accordance with the startup sequence in the machine tool manual.

2) Under normal circumstances, you must first return to the machine reference point during the startup process to establish a machine tool as a standard system.

3) After starting the machine, let the machine run dry for more than 15 minutes to make the machine reach a balanced state.

4) After shutting down, you must wait for more than 5 minutes before starting up again, and no frequent startup or shutdown operations are allowed without special circumstances.

The tip of this type of turning tool is composed of linear main and secondary cutting edges, such as 900 internal and external turning tools, left and right end face turning tools, grooving (cutting) turning tools, and various external and internal cutting edges with small tip chamfers. Hole turning tool. The selection method of the geometric parameters of the pointed turning tool (mainly the geometric angle) is basically the same as that of ordinary turning, but the characteristics of CNC machining (such as machining route, machining interference, etc.) should be considered comprehensively, and the tool tip itself should be considered strength.

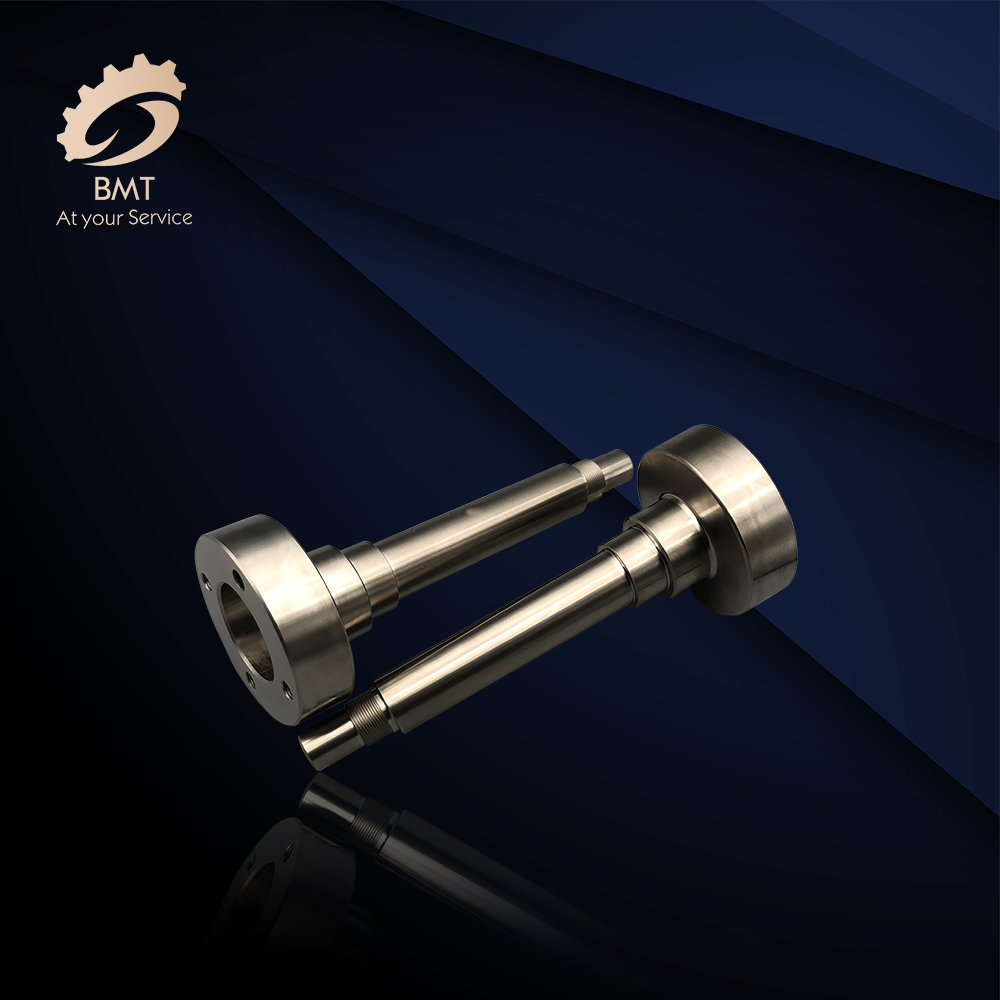

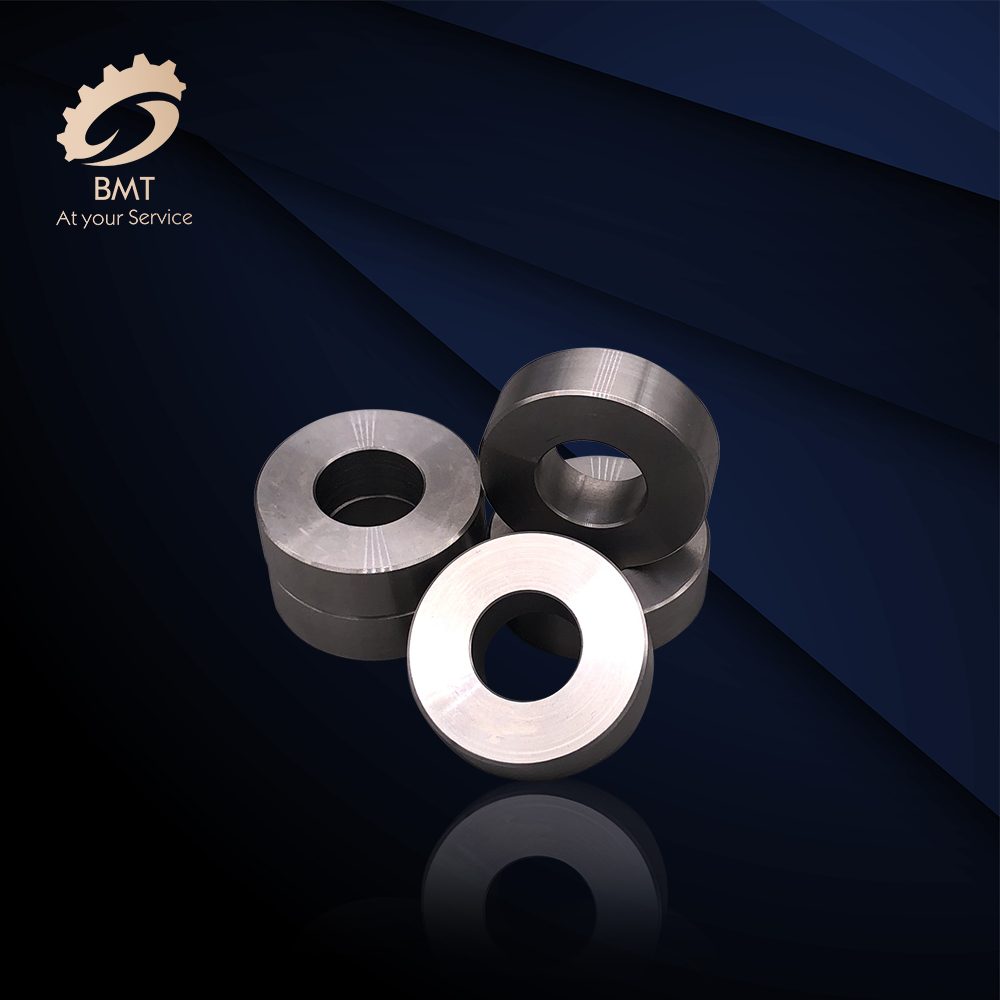

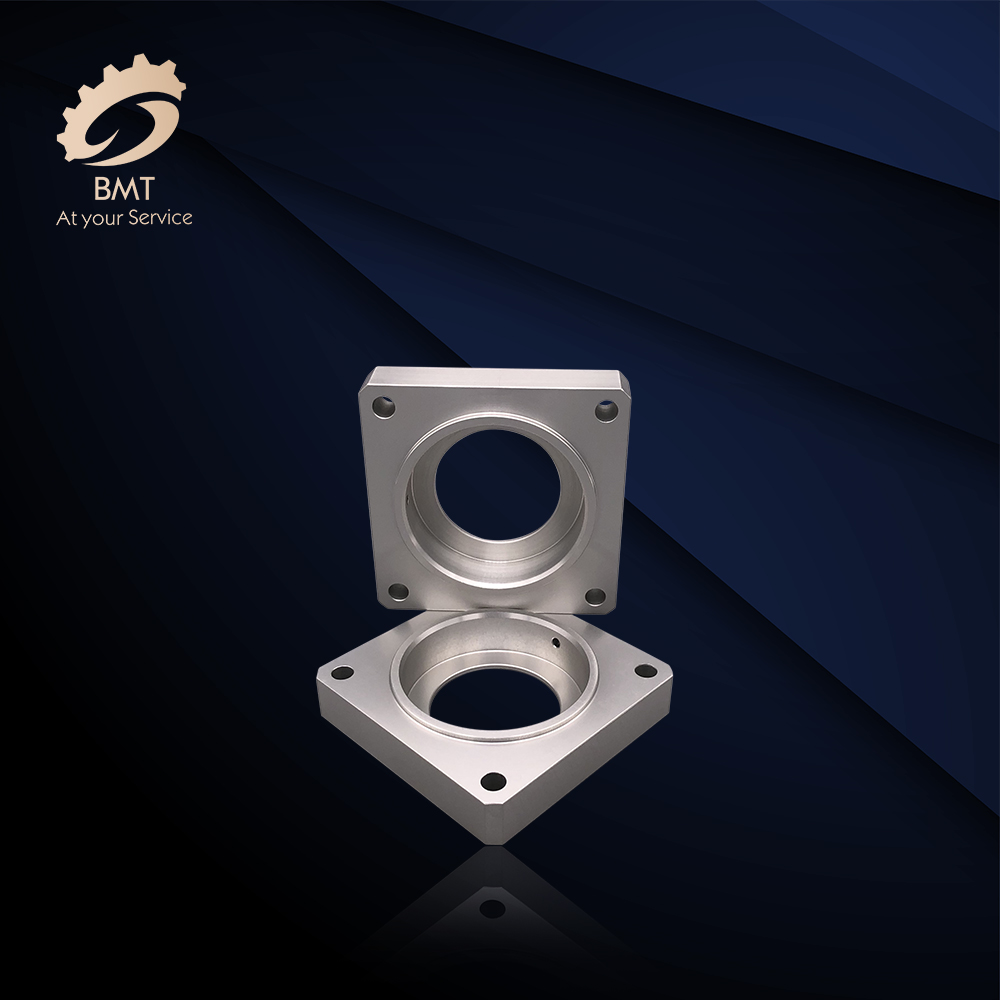

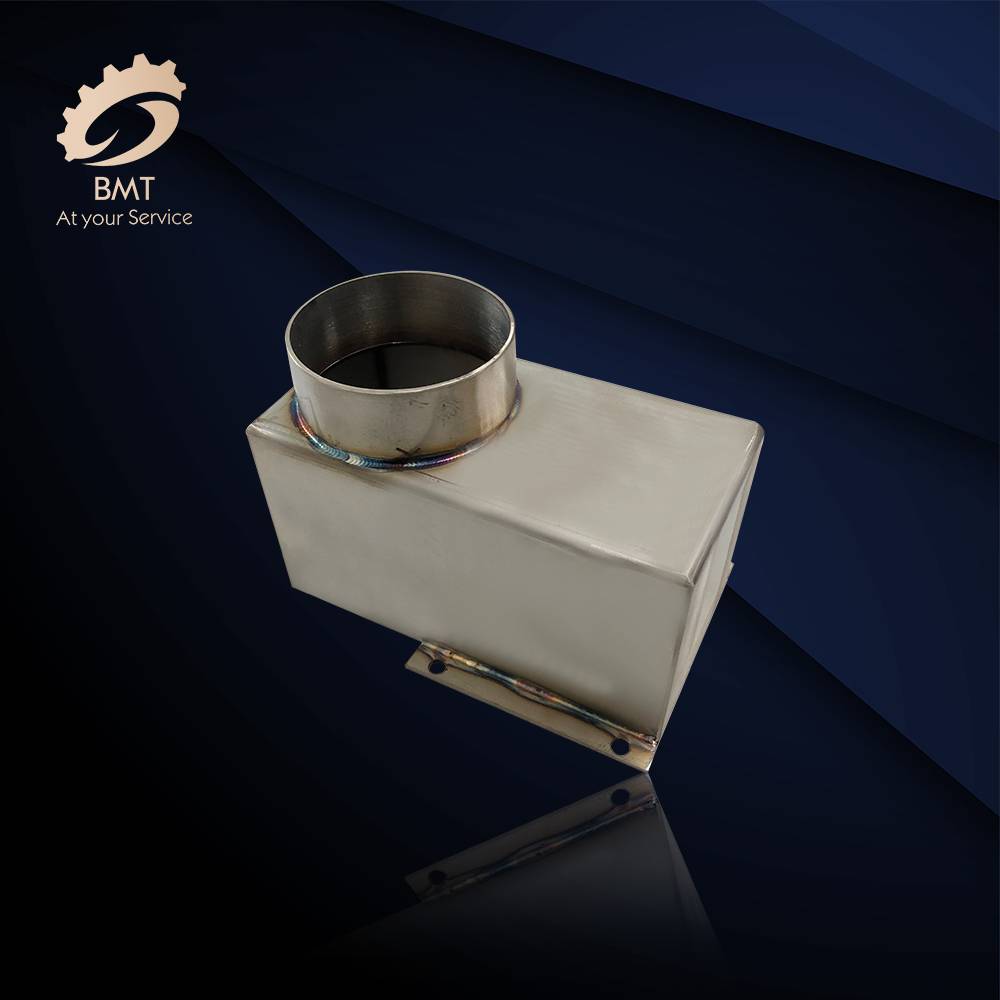

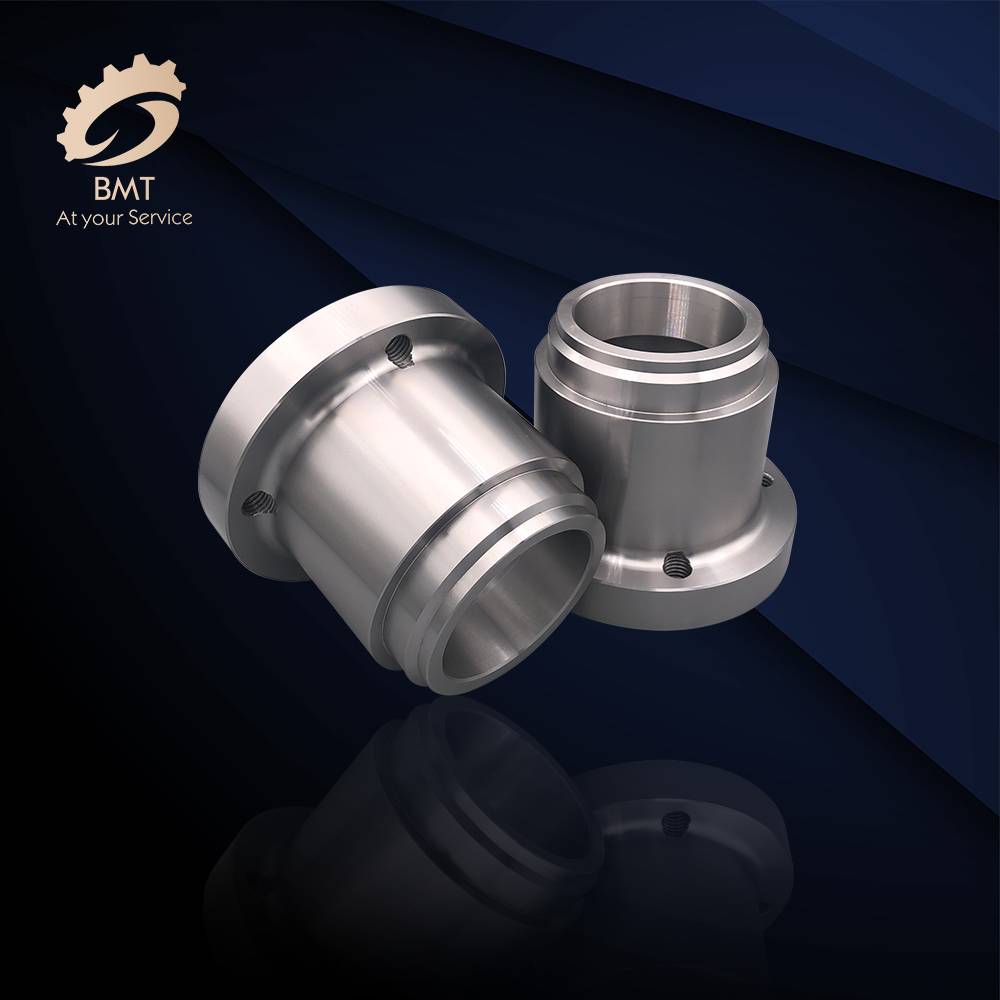

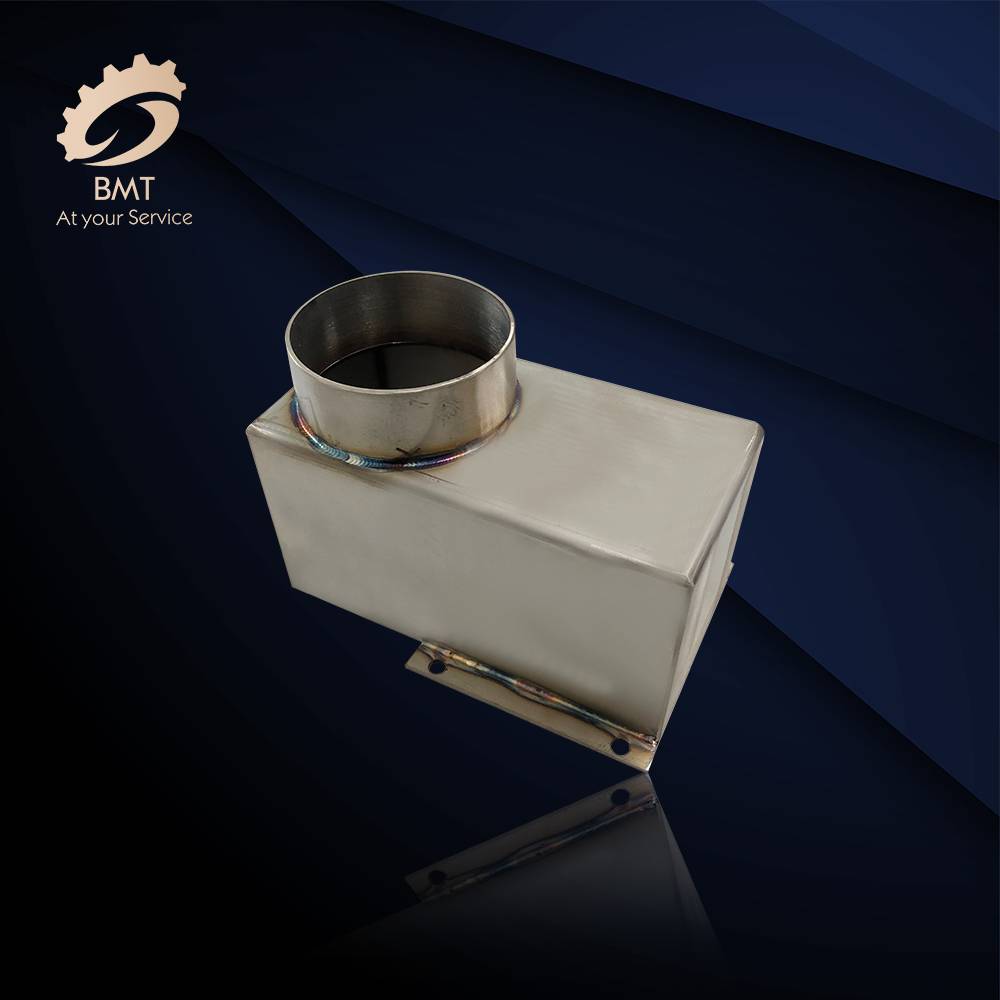

Product detail pictures:

Related Product Guide:

Adhering into the principle of "quality, provider, performance and growth", we now have gained trusts and praises from domestic and intercontinental consumer for 2021 New Style Cnc Lathe Machining - CNC Machining Civilized Production and Safe Operating Procedures – Basile, The product will supply to all over the world, such as: Spain, Angola, Czech, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

Send your message to us:

-

Wholesale Cnc Aluminum Machining - Corrosion R...

-

Lowest Price for Brass And Aluminum Cnc Machini...

-

Factory Free sample Bending Stamping Part - St...

-

Factory Free sample Cnc Machining Suppliers - ...

-

High reputation Sheet Metal Products Manufactur...

-

2021 Good Quality Sheet Metal - Stainless Stee...