Your Custom One-Stop CNC Machining Partner

Your Specialty Metals Supplier for Aerospace and Commercial Manufacturing Applications

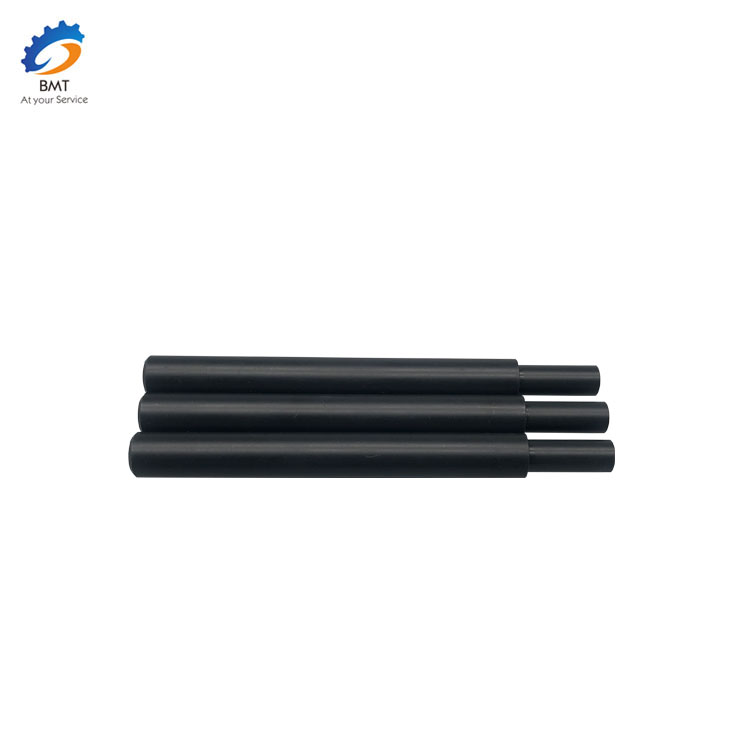

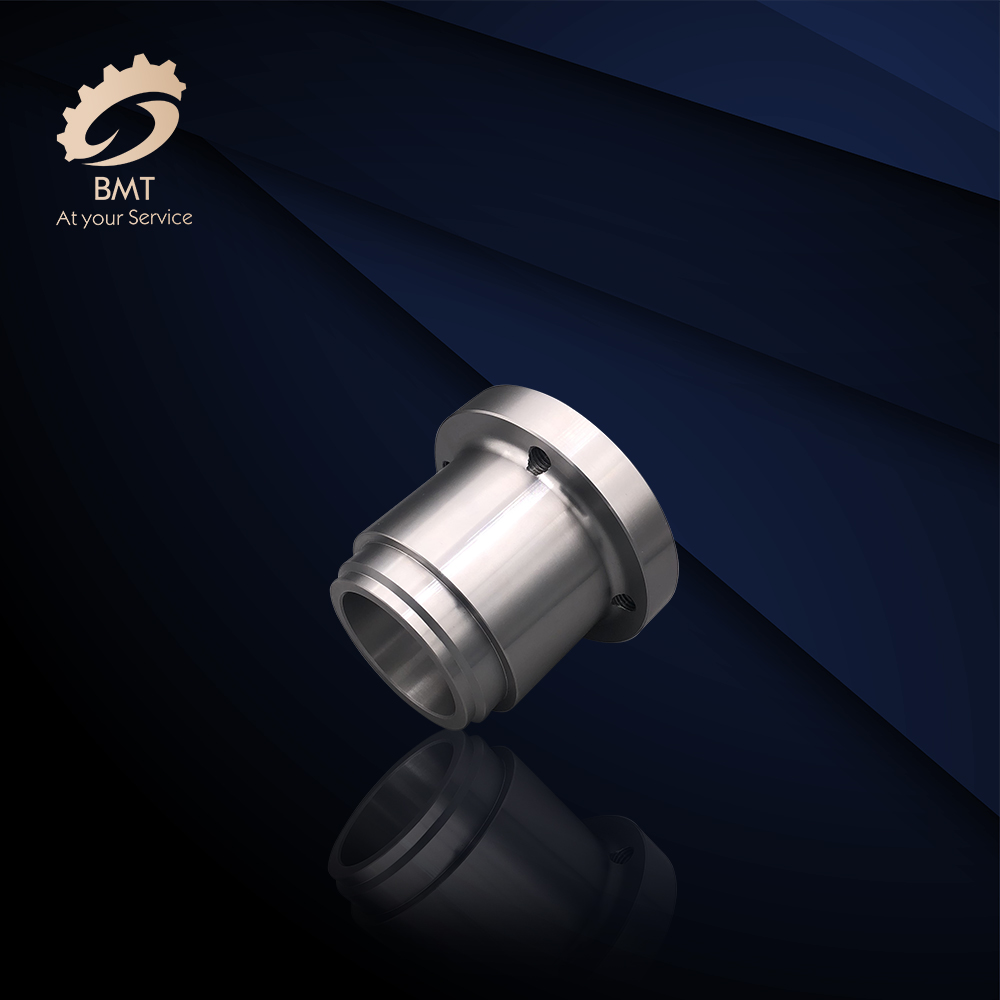

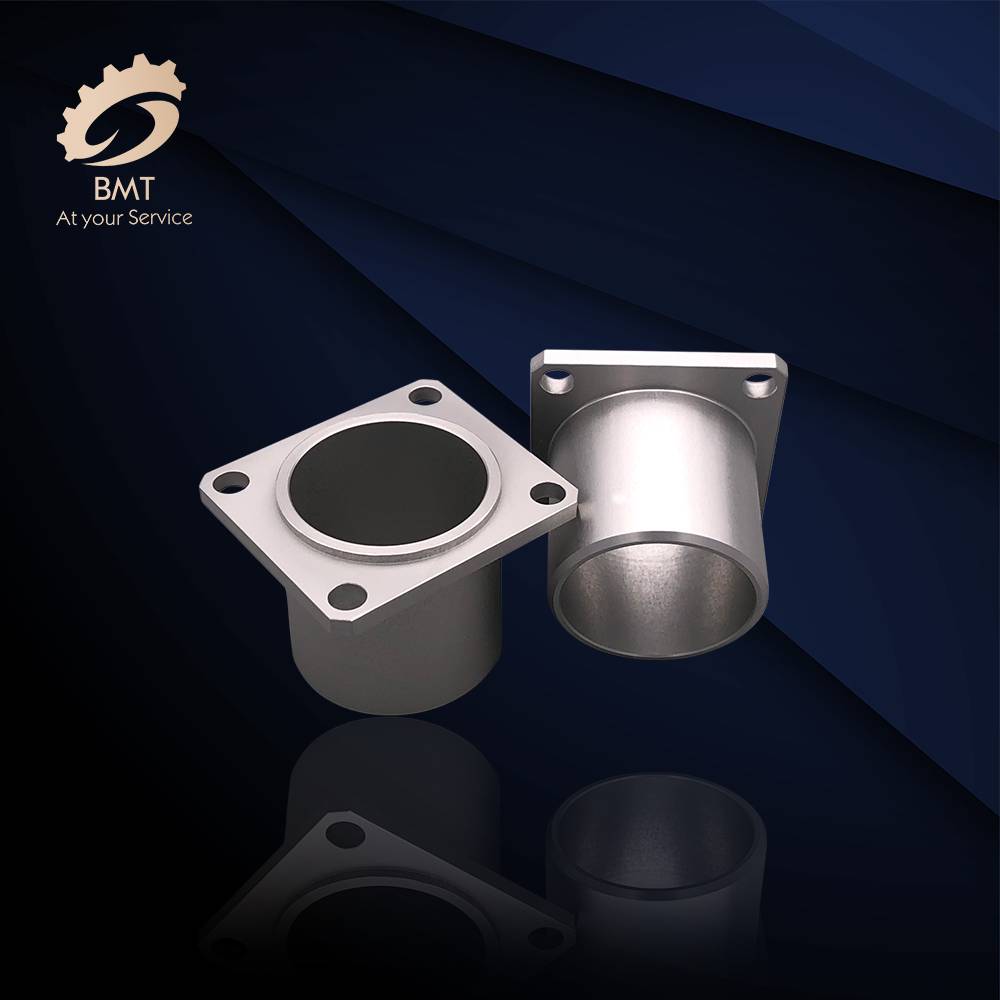

CUSTOM CNC MACHINING

There’s no simple way to describe the benefits of high-quality, precision machining and its importance in today’s economy. Just about any industry that relies on precision machined parts uses CNC machining services to create custom machined parts from raw materials, fabrications, or castings into individual components.

CNC machining, or computer numerical control machining, is a type of precision machining that’s automated, enabling high accuracy and extreme precision. Not only can attain a degree of complexity and intricacy that traditional precision machining technology can’t, it’s also cost-effective, especially when producing complex parts.

- Milling — bringing a rotating cutting tool into contact with a stationary workpiece

- Turning — rotating a workpiece to contact a cutting tool; lathes are common

- Drilling — bringing a rotating cutting tool into contact with a workpiece to create a hole

- Boring — removing material to form a precise inner cavity within a workpiece

- Broaching — removing material with a series of shallow cuts

- Sawing — cutting a narrow slit in a workpiece using a saw blade

There are huge numbers of CNC Machining Service Providers. Why should you choose US? Here are the top 3 reasons:

1. Experience

Our engineers have built up rich, deep experience from many previous projects, so they can handle complex and precision parts in several industries without a problem.

2. Advanced Equipment

BMT has extensive in-house equipment for both manufacturing and testing. Your parts will be manufactured and inspected with our advanced in-house equipment, including 3-, 4-, and 5-axis CNC milling, CMM, and ETC.

3. Fast Turnaround

On average we return quotes within 24 hours, parts ship within 7-15 days or less, and we have a 99% on-time delivery and quality rate.

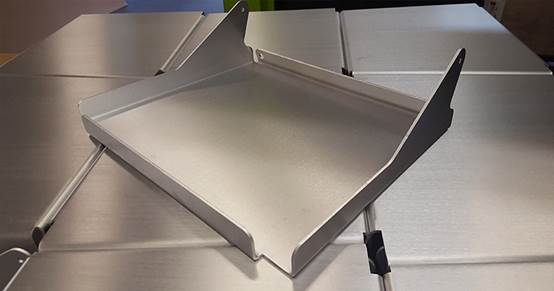

CUSTOM SHEET METAL

Sheet Metal Fabrication is an economical manufacturing solution for low to high volume steel and aluminum parts. BMT offers sheet metal parts, providing you with the flexibility to order the parts you need.

Our partner factories have vast capacity and use state-of-the-art equipment to manufacture your bespoke parts. With a wide range of finishing options, Get It Made is your go-to manufacturing partner for sheet metal parts.

BMT excels at producing high precision, complex parts for the most demanding applications, simply tell us what you need then trust us to manage the whole process for you.

BMT OEM SHEET METAL FABRICATION

Sheet Metal Fabrication is an economical manufacturing solution for low to high volume steel and aluminum parts. BMT offers sheet metal parts, providing you with the flexibility to order the parts you need.

Our partner factories have vast capacity and use state-of-the-art equipment to manufacture your bespoke parts. With a wide range of finishing options, Get It Made is your go-to manufacturing partner for sheet metal parts.

BMT excels at producing high precision, complex parts for the most demanding applications, simply tell us what you need then trust us to manage the whole process for you.

BMT has been producing custom sheet metal parts for many years, delivering high precision, complex parts to clients from a vast range of industries. Careful design considerations are required when designing for sheet metal parts and BMT offers expert Design for Manufacture feedback for all quotations.

With a wide variety of processes including CNC Machining, and Sheet Metal, BMT is your partner for a complete manufacturing solution.

Quality Assured:

- Advice on Our Design

- First Article Inspection Report

- Material Certificates EN3.1

- Tolerances: +/- 0.05mm or Better on Request

- 1-2.5 Weeks Lead Time for Complex Projects

- Delivered 2 Days Early On Average

We’re ready joining you. Get the same products, components, and services you trust from a single source: BMT.