Ways To Achieve Transformation And Upgrading 2

Realize the adjustment and improvement of the industrial structure. Appropriately expand the scale of enterprises and correspondingly increase the industrial concentration. By 2017, several or more large-scale enterprise groups of complete machines and parts with strong competitiveness will be cultivated, which will further enhance the industrial concentration and significantly enhance the leading role of key enterprises. Improve the construction machinery service industry system and cultivate the growth points of the construction machinery aftermarket. Drive maintenance, after-sales, outlets, leasing, import and export, second-hand market and other related industries to develop simultaneously.

Encourage enterprises to establish advanced information management systems, strengthen classified recycling management, improve construction machinery remanufacturing systems, and enhance the ability to recycle parts.Realize a reasonable upgrade of product structure. On the basis of the existing product capacity and technical level, increase the proportion of high-end products. Consolidate the advantages of competitive products, increase the market share in the mid-to-high-end market, and accelerate the transformation of general-purpose, low-value-added, light-duty product structure to special-purpose, high-value-added, and reasonable-weight product mix; increase domestic market share, and accelerate the research and development of high automation and environmental protection. type machinery; make various series of products more abundant, and further enhance the comprehensive competitiveness. At the same time strengthen its own brand.

To further expand the international market. With the deepening of my country's accession to the WTO, the comprehensive promotion of the "going out" strategy and the latest benefits of the devaluation of the RMB, the proportion of machinery manufacturing exports should continue to increase. Realize the research and development of products in emerging fields. With marine engineering construction machinery, urban construction waste recycling technology, urban waste treatment and comprehensive utilization equipment, construction cranes, self-propelled and self-propelled aerial work platforms, environmental protection and energy-saving storage equipment (including electric forklifts), old projects Mechanical product recycling and remanufacturing technology is the entry point, research and development of related products, and look for new economic growth points.

Realize the requirements of information technology for products. One is the realization of human-computer interaction technology. Increase the application of ergonomics, including the coordination between machines and people, improve human-machine safety and driving comfort, simplify the operating procedures of drivers, facilitate technical maintenance, and improve the working conditions of drivers.

The second is to realize intelligent technology. Increase the application of intelligent technology, including equipment interconnection based on network and fieldbus, automatic identification and communication of equipment and materials, digital model of enterprise operation and corresponding information system, etc. The third is to realize modular design.

Actively adopt modular design technology, and strive to form as many products as possible with a few modules, and on the basis of meeting the requirements, the product accuracy is improved, the performance is stable, the structure is simple, and the cost is low, and the module structure and the connection between modules should be as simple as possible.

Send your message to us:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

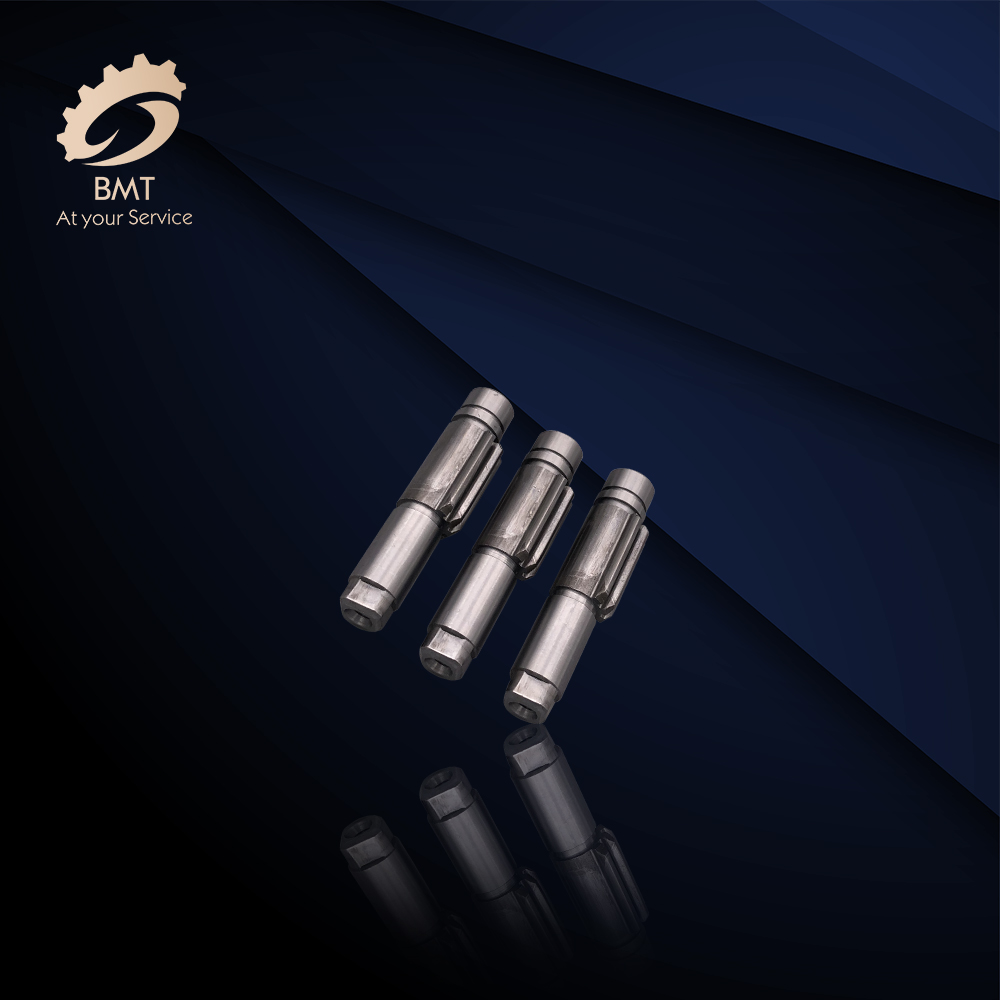

Axis High Precision CNC Machining Parts

-

CNC Machined Parts for Italy

-

CNC Machining Aluminum Parts

-

Auto Parts Machining

-

Titanium Alloy Forgings

-

Titanium and Titanium Alloy Fittings

-

Titanium and Titanium Alloy Forgings

-

Titanium and Titanium Alloy Wires

-

Titanium Bars

-

Titanium Seamless Pipes/Tubes

-

Titanium Welded Pipes/Tubes