What is CNC Machining? An Overview of CNC Machining Process

CNC is the abbreviation for “Computer Numerical Control”, first introduced between the 1940s and 1950s. CNC Machining is a manufacturing process in which pre-programmed computer software dictates the movement of all kinds of tools and machinery. The process can be used to control a range of complex machinery, including machining center, lathes, milling machine, grinding machine, etc. With CNC machining, three-dimensional cutting, milling, turning and drilling tasks can be accomplished in a single set of prompts.

CNC process runs in contrast to manual operation, where the operators are needed to guide the commands of machining tools via levers, buttons and wheels. The CNC system might resemble a regular set of computer components, but the software programs and control penal used in CNC machining distinguish it from all other forms of computation.

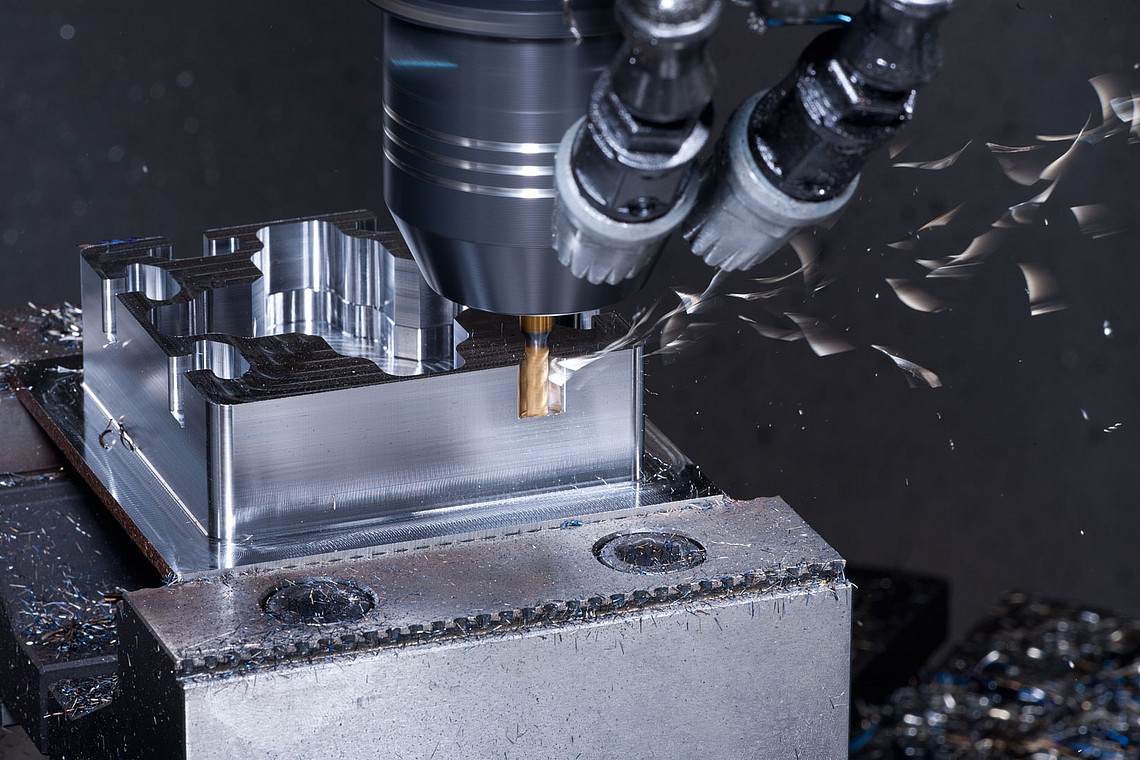

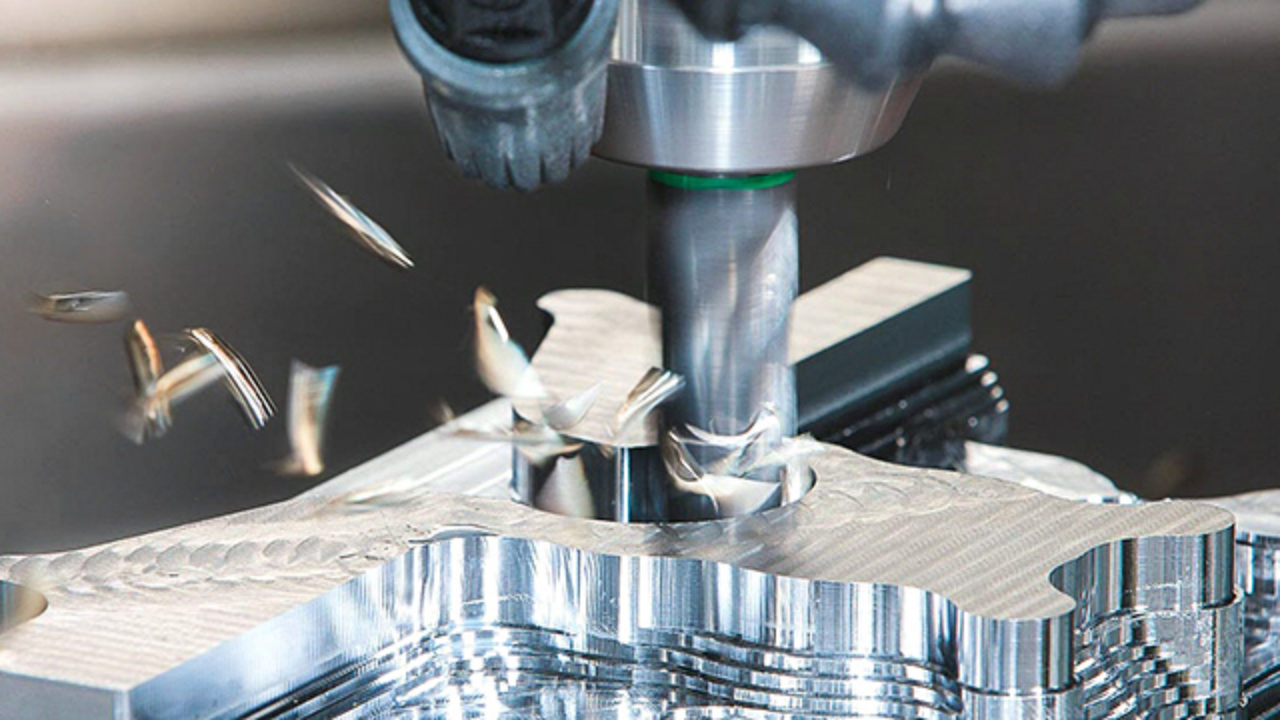

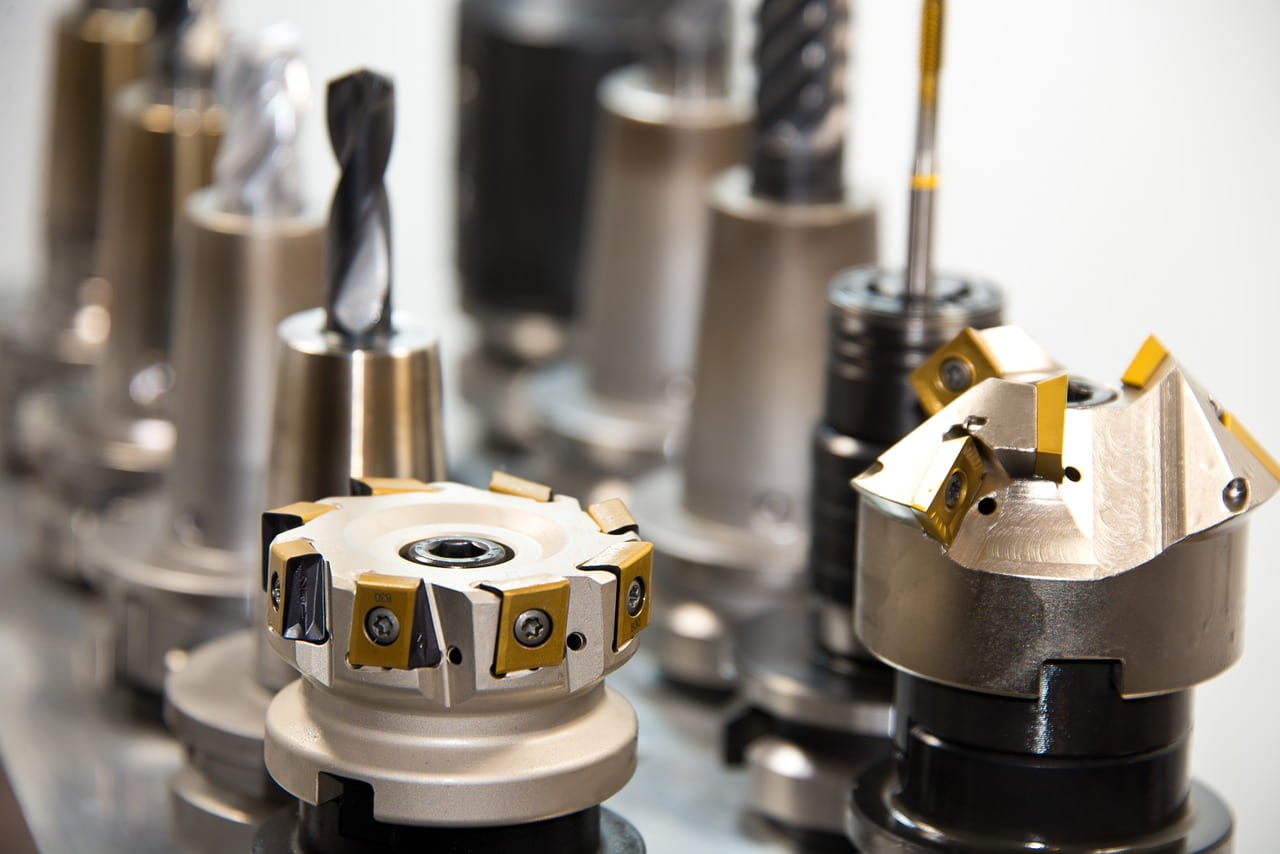

The process involves different accurate cutting instruments that working on the blank material to its designed shape from the software CAD or Solid works, with different cutting tools. This kind of process helps us in designing the product we want with the opportunity of altering and making changes.

The ultramodern CNC machining services use such software that generates computer files having different commands which allow the CNC Controller to operate the machine for production. Commonly used CNC machining services include the following functions:

√ Precision Cutting

√ High Speed Turning

√ Precision Milling

√ High Speed Drilling

√ Accurate Grinding

√ Specific Tapping

√ Precise Boring

√ High Quality Slotting

√ Custom Grooving

√ EM Shearing

√ Prescribed Reaming

√ Rotary Broaching

√ Qualified Threading

With this technology, it saves a lot of production time for the operators and production entrepreneurships. With the development and innovation of science and technology, the CNC process technology is growing in very high speed. BMT adopts fashioned superior production technology and accurate machine tools to provide the most favorable machining parts to our esteemed customers from all over the world.

If you’re engaged in one of these or any other industry that relies on the use of CNC technologies, rest assured that BMT can help you take your production up a notch. We work with a variety of materials, including stainless steel, aluminum, titanium, bronze, brass, etc. Let us know what your manufacturing processes call for, and we’ll supply you with that for a reasonable price.

For your convenience, you can find the much-needed CNC machined parts in a few clicks with the help of a search bar on our website. Feel free to send us emails or call us at any time. BMT—At Your Service!

Post time: Jan-07-2021