We've analyzed some of data collected to understand the effects of the COVID-19 pandemic on the manufacturing industry here in the world. Whilst our findings may not be indicative of the entire world industry, BMT's presence as one of China's Manufacturing should provide some indication of the trends and impacts felt by the manufacturing industry in China more widely.

What has been the impact of COVID-19 on the Manufacturing Sector in China?

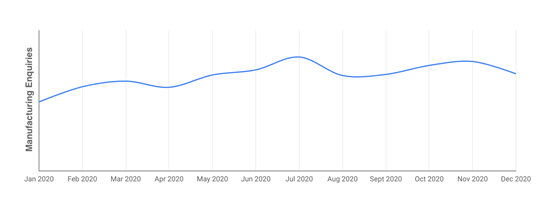

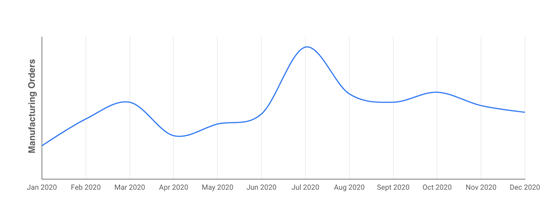

In short, 2020 has been a varied year for the manufacturing industry, with peaks and troughs dominated by external events. Looking at a timeline of key events in 2020, it's easy to see why this is the case. The graphs below show how enquiries and orders have varied at BMT during 2020.

With the vast amount of the world's manufacturing taking place in China, the initial coronavirus (COVID-19) outbreak in China affected companies across the globe. It is worth noting that as China is a large country, strict efforts to contain the virus allowed certain regions to be relatively unaffected whilst other regions shut down completely.

Looking at the timeline we can see an initial increase in China manufacturing around January and February 2020, peaking around March, as China companies attempted to mitigate supply chain risks by reshoring their manufacturing back to China.

But as we know, COVID-19 became a global pandemic and on the 23rd January, China entered its first nationwide lockdown. Whilst manufacturing and construction industries were allowed to continue, the number of designers and engineers placing orders for manufactured parts dropped throughout the months of April, May and June as businesses closed, employees were staying at home and expenditure dropped.

How has the manufacturing industry reacted to COVID-19?

From our research and experience, the vast majority of China manufacturers has remained open throughout the pandemic and has not needed to furlough their employees. Whilst high tech production businesses have been quieter in 2020, many have looked to find inventive ways to use their additional capacity.

With an estimated lack of ventilators and Personal Protective Equipment (PPE) in China, manufacturers looked to repurpose and use their extra capacity to produce parts they might not have otherwise have produced. From ventilator parts to 3D Printer face shields, China manufacturers have used their knowledge and expertise to join the nationwide effort to try and defeat COVID-19.

How has COVID-19 affected supply chains and deliveries?

At BMT, we use air freight when delivering projects from international partner factories; this allows us to deliver low cost manufactured parts in record time. Due to high-volumes of PPE being shipped to China from abroad, there have been minor delays to international air freight as a result of the pandemic. With delivery times increasing from 2-3 days to 4-5 days and weight limits being imposed on businesses to ensure sufficient capacity, supply chains have been strained but fortunately, not compromised over the course of 2020.

With careful planning and additional buffers built into production lead times, BMT has been able to ensure that our client's projects have been delivered on time.

Arrange a Quote Now!

Are you looking to start your CNC Machined Part manufacturing project in 2021?

Or alternatively, you are looking for a better supplier and satisfied partner?

Discover how BMT can help your project start from arranging a quote today and see how our people make difference.

Our professional, knowledgeable, enthusiastic and sincere team of technicians and sales will provide free Design for Manufacture advice and can answer any technical questions you may have.

We are always here, waiting for your join.

Post time: Mar-06-2021