Track and coordinate all departments of the business unit and related functional departments to solve the problems in the process and ensure the delivery date of important orders: 1) The business Unit will arrange personnel, equipment and site according to the development needs and current orders. 2) for process planning and layout, reasonably according to the production technological process, the use of workshop environment, ventilation and lighting equipment layout, dust, moisture and other requirements and field, determine the flow of material and storage, etc., and reduce the transportation and inventory, convenient for operation, production staff to reduce operator superfluous action, according to the provincial humanization arrangement process, save the production cost, 3) Recruit, hire and train personnel according to the specialty of each division, select equipment that can meet the production requirements and have high cost performance, improve the production efficiency, quality level and professional level of the division, and enhance the competitiveness of the division;

Personnel management: 1) Based on the actual situation of orders, adopt the piece-rate based and hourly auxiliary wage calculation mode, assess employees according to the quantity and quality of their work, determine the unit price of routine products, and work out the piece-rate wage system for production employees of the Business division. 3) long-term recruit and train staff professional skills and keep good working attitude and professional staff, collaborative human resources, with a reasonable compensation, benefits, company vision and values to attract and stable employees, the employees monthly and annual appraisal, good let employees get promoted and promotion, to build good management technical team;

Material management: 1) Warehouse and material personnel are responsible for the management of production materials, including raw materials, auxiliary materials purchase, tracking, access to the warehouse, account construction, etc. 2) Each branch shall be responsible for the management of incoming materials, semi-finished products and finished products. For the branch and project department with complex materials, material personnel shall be set up to be responsible for the tracking of materials, including docking with the material opening department, warehouse, spraying department and engineering department, tracking the materials in place on time, and checking the quantity and errors on the engineering table, etc. 3) Material management of each department also includes material quality, storage, protection, cleaning, scrapping, etc., and regular cleaning of idle materials, including reuse and scrapping; Quality management and equipment management. The production department shall carry out corresponding quality management and equipment management according to the quality management system and equipment management system.

Cost control: 1) The production department calculates the actual production cost of various orders, including the consumption of raw materials and auxiliary materials, labor costs, etc., calculates the direct production cost of orders and provides it to the business division to calculate the profit of orders. 2) The production department calculates and analyzes the production costs of each division, conducts on-site and data research, improves production process, improves production efficiency and reduces production costs, including materials, labor, electricity and auxiliary materials; Production safety and fire safety: 1) The production department strictly implements the company's production safety and fire safety system, and makes safety production rules based on safety problems in the production process, including driving use, workpiece lifting and transportation

Operating machine tools, production safety and fire safety training to employees, 2) implement the daily production safety and fire safety supervision and inspection, according to the system and the detailed rules to guide and supervise daily work site management and staff operation, 3) a safety accidents according to the system for processing, fill out the security incident report, reason analysis, responsibility, and formulate corrective and preventive actions; Site management: 1) Daily implement 5S field management method, implement fixed management, keep equipment, workplace and environment neat and tidy, and carry out daily supervision, inspection and correction, so that employees can develop good habits; 2) Kanban management: make bulletin on the data and reports of production statistics such as quantity, quality, safety and cost, and publish the detailed rules of important manufacturing processes, so that employees can understand the operation of the business division and production, improve the manufacturing process and quality control level, and improve production efficiency;

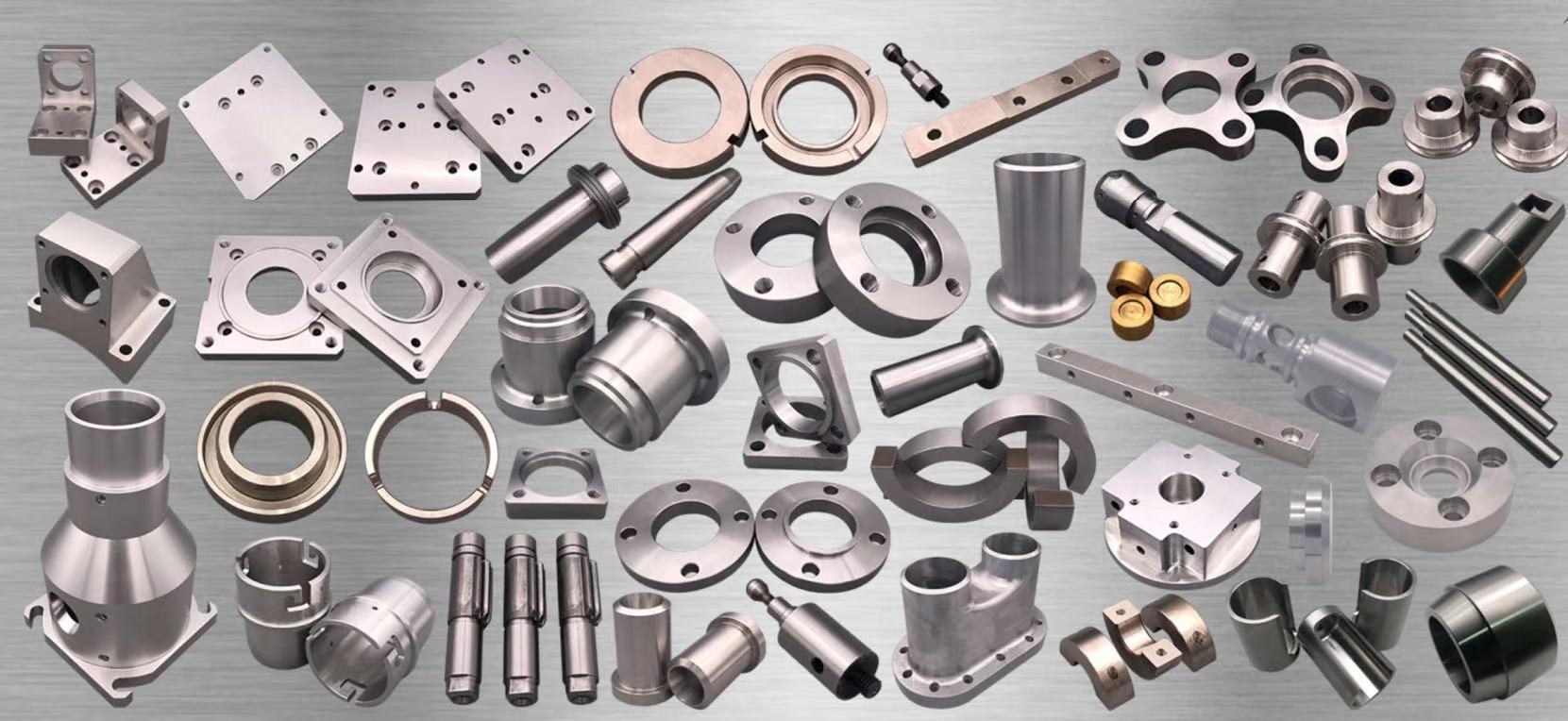

Manufacturing process management: 1) Each division shall produce according to the process sheet, process flow card and drawing in the production process to ensure the accuracy of products and reasonable process methods. 2) in the process of production of drawings and/or process is not reasonable to the engineering is put forward, and the content of the correction by engineering, in addition, on the one hand, fully understand customer requirements, on the other hand, the process of production at the scene to encourage technology improvement and perfect production employees, let staff positive Suggestions, refinement and improvement of manufacturing process and form file, as a guide for production process document.

Post time: Nov-16-2021