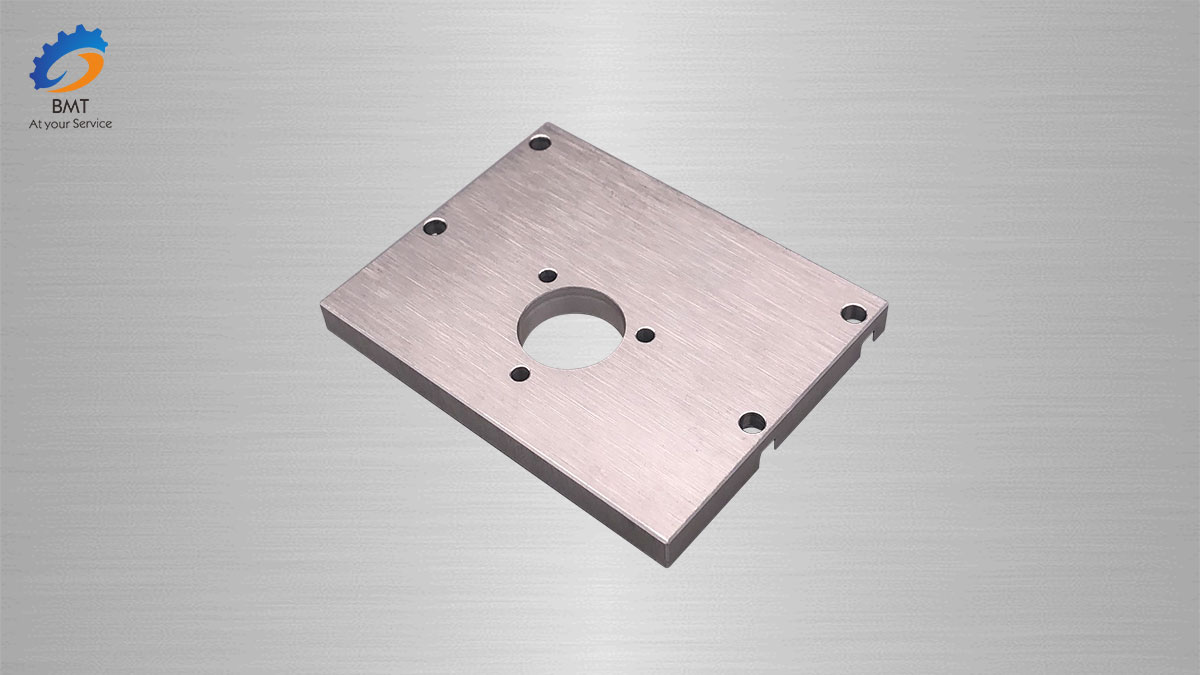

CNC Machining Processing Analysis

Process analysis

The technical issues of CNC machining of the processed parts involve a wide range of aspects. The following combines the possibility and convenience of programming to put forward some main contents that must be analyzed and reviewed.

Folding dimensions should conform to the characteristics of CNC machining

In CNC programming, the size and position of all points, lines, and surfaces are based on the programming origin. Therefore, it is best to give the coordinate size directly on the part drawing, or try to quote the size with the same datum.

The conditions for folding geometric elements should be complete and accurate

In the programming, the programmer must fully grasp the geometric element parameters that constitute the contour of the part and the relationship between the geometric elements. Because all geometric elements of the contour of the part must be defined during automatic programming, the coordinates of each node must be calculated during manual programming. No matter which point is unclear or uncertain, programming cannot be carried out. However, due to inadequate consideration or neglect by part designers in the design process, there are often incomplete or unclear parameters, such as arc and straight line, arc and arc whether they are tangent or intersecting or separated. Therefore, when reviewing and analyzing the drawings, you must be careful and contact the designer in time if you find any problems.

Reliable folding positioning datum

In CNC machining, the machining processes are often concentrated, and it is very important to locate them on the same basis. Therefore, it is often necessary to set some auxiliary datums, or add some process bosses on the blank.

Fold uniform geometry type or size

It is better to adopt a uniform geometric type or size for the shape and inner cavity of the part, so that the number of tool changes can be reduced, and it is also possible to apply a control program or a special program to shorten the length of the program. The shape of the parts is as symmetrical as possible, which is convenient for programming with the mirror machining function of the CNC machine tool to save programming time.